All You Need to Know About Orca Slicer

In today’s FDM 3D printing landscape, Bambu Lab is a major player. On social media, in printing forums and at international trade fairs such as Formnext, the Chinese manufacturer is on everyone’s lips and in high demand. But 3D printing cannot be done with printers alone. In additive manufacturing, slicers are needed to generate the so-called G-Code, a language that can be understood by the 3D printer. Although Bambu Lab has already excelled in this area with the Bambu Studio, their Orca Slicer software is another highlight from the Bambu Lab sphere. But what’s all the hype about this software, does Orca Slicer deliver what it promises, and is the uproar from the 3D printing community justified?

Orca Slicer was first released in July 2022 and was originally known as Bambu Studio SoftFever. This is due to the fact that it is based on a fork of Bambu Studio and PrusaSlicer and was developed by Bambu Lab user SoftFever. Orca Slicer also has many of the functions of the aforementioned slicing models and also contains SuperSlicer options, especially calibration functions. It was developed to extend the limits of Bambu Studio.

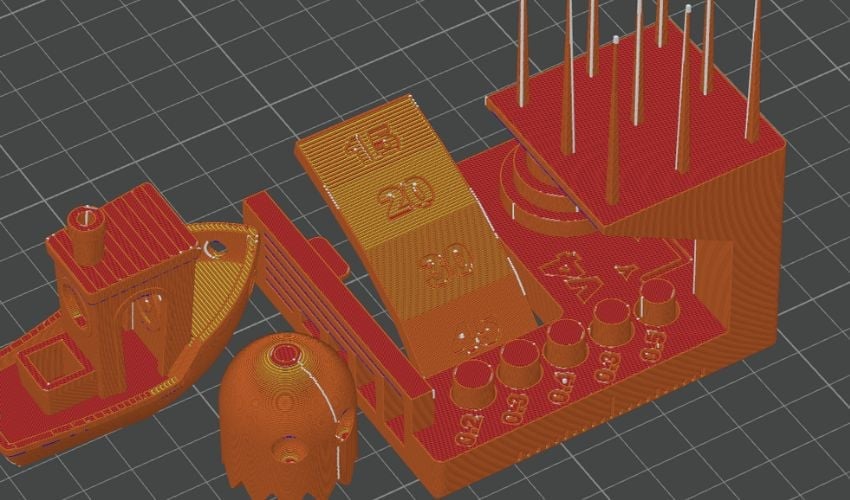

Orca Slicer takes advantage of Bambu Studio’s ease-of-use (Credits: Bambu Lab)

As Orca Slicer also uses the functions of other slicers, it offers important advantages for the user. On the one hand, the tool portfolio is much more interesting and expanded. On the other, the program is an open source slicer for FDM 3D printers. This is because Orca Slicer has evolved from Bambu Studio, which is based on the open source PrusaSlicer, which in turn is based on Slic3r, which is also open source. Although Bambu Lab tries to keep its environment as closed source as possible, this is not possible if the final products are based on open source models. Therefore, Orca Slicer is a free and open source solution.

At first glance, Orca Slicer is not so different from Bambu Studio. The differences only become apparent with advanced use. The program has a wider range of tools and more functions, which are interesting for better and more detailed print results. Despite its ease of use, Orca Slicer can be used to produce high-quality prints.

In addition, larger projects with multiple print jobs can be realized, and AI print fault detection ensures that manufacturing errors are prevented. The cutter automatically checks for updates so that the latest version can always be retrieved. Tips for each tool make using the various functions to adjust prints even more intuitive and faster. This is a suitable option for all those who like to play around, try things out and have the whole printing process from A to Z in the palm of their hand. For simple things, Bambu Studio is enough, but for advanced prints, Orca Slicer is ideal as it unleashes the full manufacturing potential.

Compatibility and Installation

Orca Slicer is compatible with Windows, Linux and Mac. You can always find the latest version of Orca Slicer on GitHub, where you can download it for free. After installation, you can configure the 3D printer. Only four or five steps are necessary to set it up:

- Select region: Here you can choose between China, Europe, North America, Asia and Others. The localization is only relevant for Bambu Lab 3D printers.

- Selecting the 3D printer: Orca Slicer already has many printer profiles configured. Therefore, you can use a preset profile or create your own.

- Select filaments: Supported materials include PLA, ABS, TPU, PC, PETG, ASA, PA, PA-CF, PLA-CF and PVA. Print settings for the respective filaments are also preset.

- Install the Bambu Network plug-in: This plug-in enables print job submission via WLAN, remote access, live transmission of print jobs and synchronization of user data. This is especially important with a Bambu Lab printer. If this is not the case, users can set up Octoprint or other remote print management services.

- Create Bambu Lab account: This step is optional but interesting for those who have a Bambu Lab 3D printer. This way they will be able to control the printing jobs through the mobile app.

Once these settings are completed, you will directly access the slicer screen and can test the actual workflow and Orca Slicer functions. Under “New project”, you can load a 3D model and define the print, material and slicer settings. This is not necessary if you are using a preset printer profile where the layer height settings are already included.

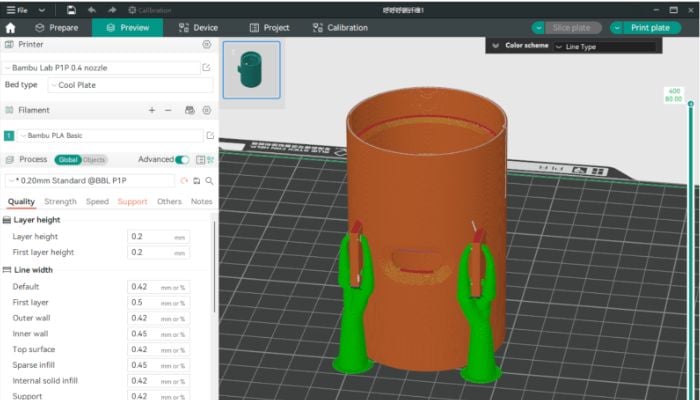

Otherwise, you can choose from four presets to define the nozzle parameters, with the options Quality, Thickness, Speed, Support and Other. The height and width of the lines can be set in Quality. Walls and fills can be set under Thickness. Speed is dedicated to acceleration and retraction values and print speed. The Support area is used to adjust the necessary support structures. There is also an area with mixed settings, which appears under Other. Here you can optimize, for example, the G-Code output.

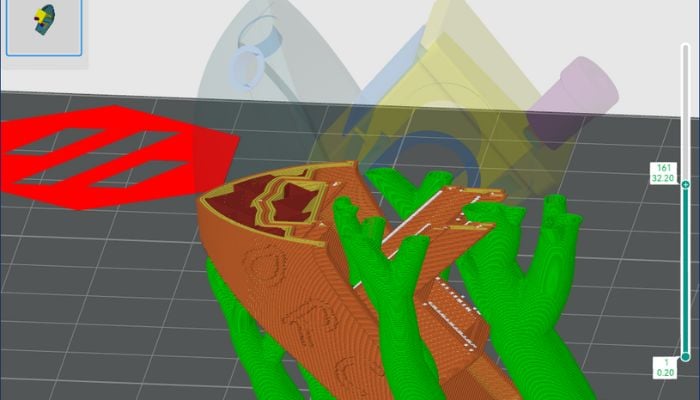

Photo Credits: Orca Slicer

The predefined print profiles and the possibility to set up new profiles by the user in a convenient and easy way are certainly some of the advantages of Orca Slicer. Users also appreciate that the software offers the user-friendly Bambu Studio platform and can now be used with other printers. They can also perform multi-plate lamination. Let’s take a closer look at Orca Slicer’s many features.

Orca Slicer Features

As mentioned, Orca Slicer impresses with a wide range of tools for advanced 3D printing. One example is Multi Plate, the multi-plate option that allows you to add multiple build plates. This allows multiple parts to be loaded and cut for a print project. Individual values can be set for each part in terms of temperature, fill, support structures and adhesion to the print bed.

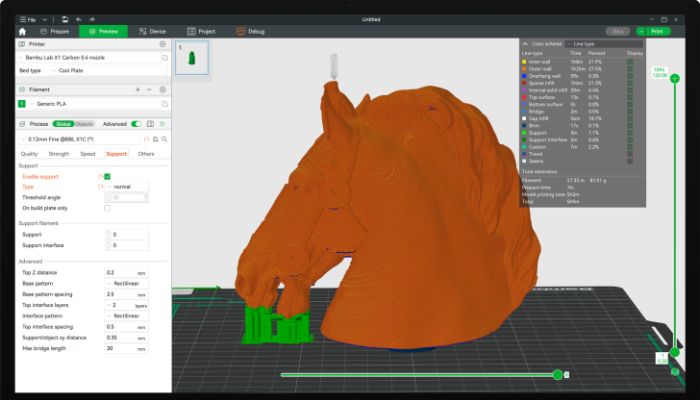

Although other slicers can also do this, Orca Slicer builds on the ease of use of Bambu Studio to make the functions simpler. Orca Slicer uses AI to automatically detect the required substrates and it is possible to print them at a different speed. It is also possible to define the printing speed of the first layer, which can be useful in multi-part jobs to avoid damage to this layer. Speed and acceleration can be defined separately for fillers and inner walls. The main advantage of Orca Slicer is that it makes the positive user experience of Bambu Studio accessible to non-Bambu Lab users and offers advanced calibration settings.

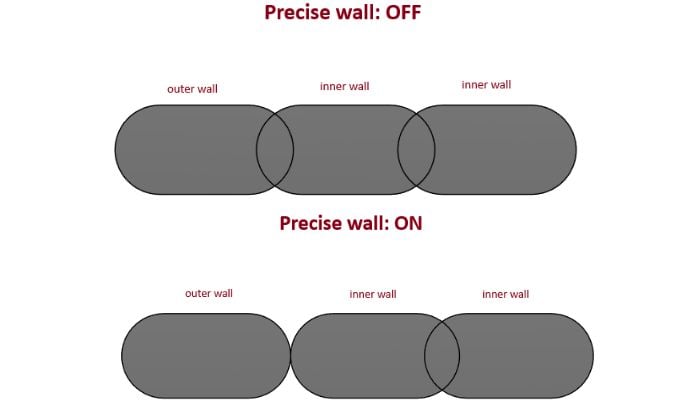

Some other functions are explicitly intended to increase the print quality, such as the sandwich mode. This inside-outside-inside mode is an enhanced version of the Outside Limits First mode. The Precise Walls function also makes it possible to fine-tune print jobs. This makes it possible to control the flow rate during the production of both walls, which results in higher accuracy. This is especially interesting when using materials such as ABS, which are prone to warping.

To avoid imperfections, there is the Seam Gap feature, which slows and stops the flow of material just before the end of a layer to avoid Z-seams, a problem in FDM printing caused by excess material being extruded from the nozzle during layer change. Another feature that evens out seam lines is loop cleaning. This setting is automatically activated and ensures that the nozzle moves slightly inward when a layer loop has been completed. In addition to these functions, it should also be noted that Orca Slicer offers clipper support and that remote control of the printer is also possible.

Photo Credits: Orca Slicer

Depending on the complexity, lamination may take some time. Even so, it can be viewed and checked before printing. There are also several options for sending the print job to the machine. The file can be exported and transferred to a memory card. If the printer uses Octoprint or Klipper, it is possible to send the file directly from the Orca Slicer to the machine. Simply enter the IP address of the printer beforehand. This way nothing stands in the way of production.

No slicing software is perfect, and Orca Slicer also has some limitations. According to user feedback, there are frequent bugs and problems. However, they are constantly working to fix them as soon as possible and provide users with a new update. The latest version V2.0.0 was released in March 2024. You can download the latest version of the software here.

Photo Credits: Orca Slicer

What do you think of Orca Slicer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: GitHub