PrusaSlicer, the Free and Open-Source Slicer for FDM and SLA 3D Printers

PrusaSlicer is a slicer software by famed 3D printer manufacturer of the same name, Prusa. The software is based on the open source slicer Slic3r, which Prusa has enhanced with a number of improvements to meet the requirements of users of its FDM and SLA 3D printers. What sets PrusaSlicer apart can be summarized in a few key points: free, open source, feature-rich and frequently updated. The tool contains everything you need to export the print files for the 3D printer and is suitable for beginners, advanced users and professionals alike.

The first version of the Prusa slicer was released in November 2016 – at the time, the software was still called Slic3r Prusa Edition. The software only changed its name in 2019 to avoid confusion with Slic3r, which was developed by Alessandro Ranellucci. Slic3r is powerful and versatile, but some of the functions are difficult to use or hidden and therefore difficult to see.

The PrusaSlicer is constantly being revised and improved. Thanks to feedback from the community, Prusa is always aware of the slicer’s weak points

Although PrusaSlicer is based on Ranellucci’s solution, Prusa has redesigned the user interface and made it easier to access the different functions. This makes the user interface clearer to see and more intuitive to use. Thanks to feedback from the Prusa community, Prusa is always aware of the slicer’s weaknesses and the developers of the Prusa Research Team are constantly striving to fix the shortcomings and add new functions.

3D Printing With PrusaSlicer

Slicing in additive manufacturing is a crucial step in the process of creating a part. Among other things, it enables careful slicing of the layer model and generates print supports if required. There is currently a variety of slicer software on the market, each designed for a specific machine and therefore different technologies.

The Prusa Slicer solution was developed for FDM and resin printers and is one of the first slicers suitable for MSLA printing. PrusaSlicer includes all printer profiles, including third-party printers. However, when used with an original Prusa printer, users get more than 180 tested and automatically updated profiles for filaments and resins.

PrusaSlicer can be easily downloaded from the Prusa website and installed on Windows, Mac and Linux. The slicer is compatible with the following formats: STL, OBJ, 3MF and AMF. It is also possible to import a STEP file. This eliminates the need to convert CAD models into STL files.

Once you have imported your model, PrusaSlicer will guide you through the alignment of the part. In this step, you can also edit your object as you wish using the various functions. Then select your 3D printer, the material used and a print profile. This is followed by the step of adding any supports and fillings. You can then view the G-code before printing to check it for errors before printing.

PrusaSlicer has a broad portfolio of materials and support structures

The Main Features

The software has a very clear user interface in which all functions are grouped together on a sidebar to make the operator’s work easier. Here you will mainly find functions for adding materials, selecting the layer height for each part of the workpiece, 150 print profiles for filaments and resins, but also some more advanced functions.

For example, you can paint user-defined supports directly onto the model or select from a pool of automatically generated support blocks. For multi-material printing, you have the option of coloring the object with a few mouse clicks and programming the color or filament change in the slicer.

In addition, PrusaSlicer offers a built-in shape gallery, the option of group selection for editing multiple objects and adaptive infills. The “Smart Fill” tool can be used to add color to a larger area, and the “Brush Tool” can be used to do this manually.

The PrusaSlicer has an extensive range of shapes and many infill options

The Latest Versions of PrusaSlicer

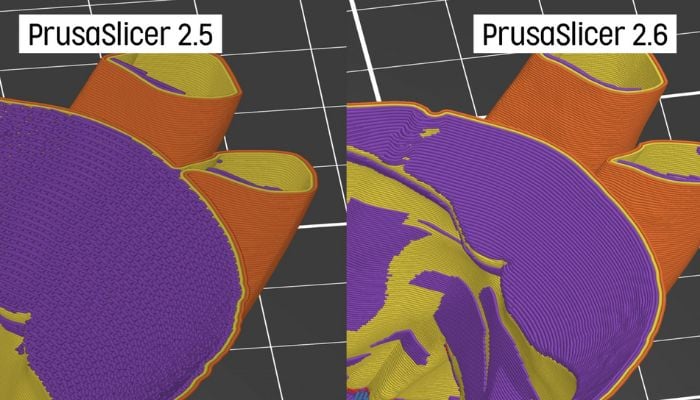

As mentioned at the beginning, PrusaSlicer is constantly being revised and improved. In June 2023, version 2.6.0. brought some new features. For example, tree supports, which originally from Cura, were implemented and enable the branching of organic supports.

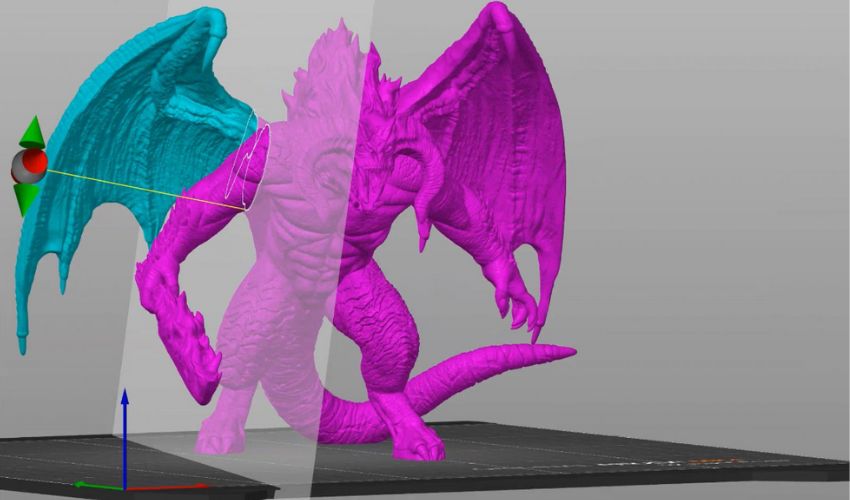

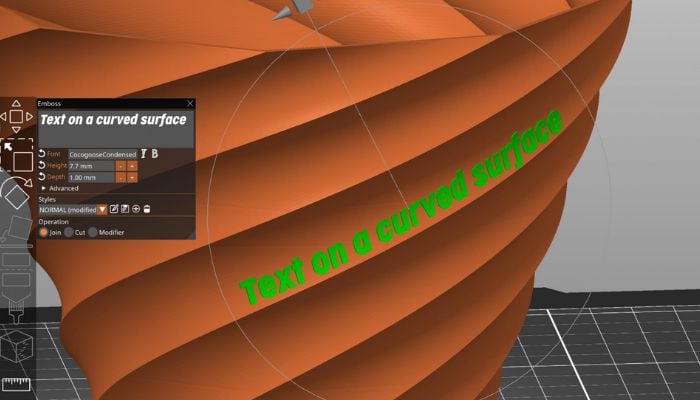

A text embossing tool has also been integrated, which allows text to be inserted and edited as a 3D object. For example, notes, characters and print serial numbers can be added directly in the slicer. An intelligent measuring tool has also been integrated, which measures the distances between vertices, edges and planes. In addition to numerous other tool integrations, the improvement of the Cut tool is also notable. This allows you to recut the model at any angle and determine the alignment.

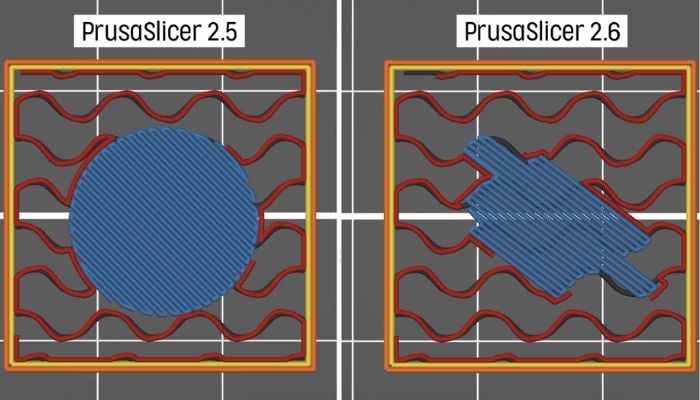

The latest version from September 2023 included a few more new features. Prusa improved the arrangement function for this version. Objects can now be placed in concave areas formed by other objects. Furthermore, there are now three different levels (fast, balanced, accurate) of geometry handling, which can be selected via the drop-down menu in the “Arrange” dialog box. The cutting and text embossing tools of the previous version have been revised and improved again. You can view all the functions on the Prusa website and download the latest version HERE.

The latest versions allow you to insert text

Have you already used PrusaSlicer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Prusa