Additive manufacturing applications by sector

When the advances of additive manufacturing began, no one thought that this technology would be able to revolutionize the industry to the extent that it has. While the main reason for its creation was to accelerate rapid prototyping; over the years, it has developed itself further than this, bringing great benefits to different sectors such as reduced material use, lowered costs, and production acceleration.

According to the Gartner 2017 curve, 3D printing is now a fully established technology in the manufacturing industry for prototype development. With this foundation, 3D printing will be able to develop itself even further, as different industries begin implementing this technology into their companies. As the revolution continues through the medical sector, art, and automotive, there is no telling what tomorrow will bring for the future of 3D printing!

Medical

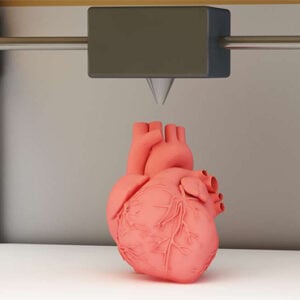

Since the 1990s, Bioprinting has been a staple in additive manufacturing that is directly applied to the medical field. Since the first break through in 1999 with a 3D printed human liver, there are many companies who have become the pioneers of this technology, such as Organovo, the creators of the first commercial bioprinter, the NovoGen MMX, as well as different universities, and companies that have machine models to meet this new trend. Today, the technology has continued to grow and innovate into a strong and vibrant part of the 3D printing world, which is expected to grow by 36% by the year 2022.

In addition to bioprinting, another big sector of additive manufacturing in health is prosthetics. Thanks to the customizability that 3D printing offers, the impact that it has had on this industry has been phenomenal. The ability to easily transport 3D printers has made it a key tool in conflict zones to help those who have lost limbs, with MakerBot being one of the leaders in this area of healthcare. Additionally, a growing trend is being seen in hospitals around the world who are now incorporating 3D printers into their facilities to help meet the needs of their patients such as through additive manufacturing prosthetics as well as turning to 3D printing for the creation of 3D printed organs to practice on before operating on patients.

Transport

Additive manufacturing could be well on its way to transforming the way we move, as it has quickly begun to revolutionize the different sectors surrounding transport. From aeronautics and aerospace to automotive and maritime; these sectors are looking to spend less time and money and have found a friend in this technology. In sectors such as aerospace, where 2.2 pounds of material can cost upwards of $150,000, this technology is providing a new way to offer cheaper and better results than typical manufacturing technologies.

It is for precisely this reason that additive manufacturing has become the go to technology for transport industries across the world who are looking to create lighter, stronger and more resistant equipment that can match the needs of the companies. The democratization of additive manufacturing of different parts is also bringing enormous technological and pragmatic advances in the automotive and transport sectors. Examples of this can already be seen in bigwig companies, such as Mercedes-Benz as well as in projects spanning from water to land. While additive manufacturing is still at its only at its forefront, this technology is offering an incredibly promising future for the transportation industries.

Architecture

In the 1980s, more and more architects and building engineers began to use computer-aided design (CAD) to design and built buildings from a computer. With the rise of additive manufacturing, many architectural firms have discovered the potential of this new technology, especially for the construction of models. Thanks to additive manufacturing, it is now possible to build very precisely, with great detail. The number of architects using this technology is growing rapidly, as many firms were already familiar with CAD well before additive manufacturing became available.

In 2017, Russian company Apis Cor presented their first 3D printed house that they built in only 24 hours! A feat in the architecture sector that was created thanks to a removable arm that is capable of extruding concrete. Since then, 3D printing has not stopped at only creating buildings, but has started to expand into the creation of bridges such as in China and the Netherlands. In addition, NASA has begun their own studies on the possibilities of using 3D printing to print an entire moon village on Mars.

Art & Design

Additive manufacturing technologies give you the power to break the limits of imagination, with proof being in the incorporation of it within the works of artists and designers around the world. Thanks to its ability to break barriers, bringing forth personalized and creative works, it is slowly becoming the go to technology for modern day artists.

Thanks to additive manufacturing, we have seen a rapid increase of projects that push the limits of an artist’s creative capabilities. Examples of this can be seen in the 3D printed fashion collection by Danit Peleg, Dinara Kaskos exquisite cakes, Zaha Hadid’s 3D printed structure, and Diana Law’s 3D printed jewelry. These are only some examples of the latest developments of 3D printing in the artistic world, with plenty more creations yet to come as artists continue to explore the possibilities of 3D technologies.

Other

Additive manufacturing is used in many other sectors other than the main ones we mentioned above. 3D printing is without a doubt a technology that has upset our entire society because it facilitates creation and personalization, allowing all who use it to meet and exceed their needs. This technology makes it possible to overcome certain obstacles and complexities, with an excellent example being seen in space exploration as additive manufacturing offers new possibilities to discover the richness of space with new satellites or potentially, the creation of our own moon bases.

In addition, 3D printing also offers more solutions in robotics by enabling the rapid manufacturing of robots that are more efficient and realistic; whether by makers or professionals. As additive manufacturing becomes more and more democratized and more accessible, we can see dramatic increases in developments within sports, music, and even in the lives of our furry friends! The surprises additive manufacturing has in store for us around the different sectors has yet to be seen but we are sure that it will accelerate innovation around the world!