Slic3r: A Free and Open-Source Slicer to Prepare 3D Models

Among the many different 3D printing software available, slicers serve as an intermediary between a 3D model and the 3D printer. More precisely, the slicer cuts a 3D model into a succession of layers that will be 3D printed by the machine. The instructions to print these layers are converted into a special language called G-code, which a 3D printer can follow. Due to their importance, numerous slicers are available on the market, and cater to various levels of experience in additive manufacturing. However, today we will take a closer look at a well-known slicing solution: Slic3r.

Slic3r is open-source software independent of commercial companies or printer manufacturers. It was launched in 2011 as part of the RepRap community, led by Alessandro Ranellucci. It’s a non-profit project, so Slic3r can be downloaded free of charge from the official website or Github. Version 1.3.0 is currently available, after 48 different official versions! It is compatible with the main file formats on the market – STL, AMF and OBJ – and easily generates G-code or SVG files. It’s a particularly popular slicer, used on many machines: UltiMaker, Prusa Mendel, MendelMax, TAZ, Rostock, etc.

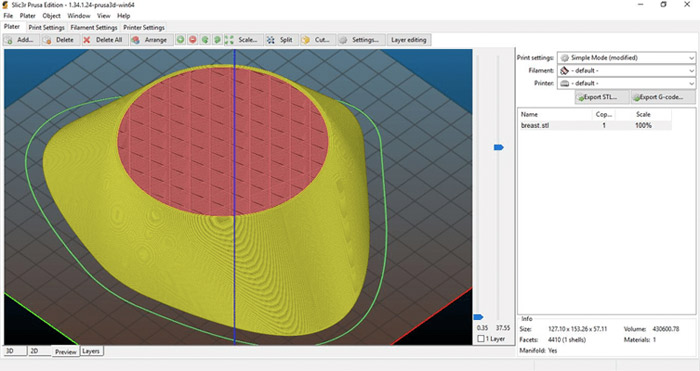

Photo Credit: Slic3r

First Steps

The first step is to download the software – it is compatible with Windows, Mac OS X and Linux. Windows users can choose between 32- and 64-bit versions adapted to their system. After downloading, simply install Slic3r. Before the first print, it’s essential that the 3D machine is properly calibrated, as the software and, ultimately, the print quality depend on it. If, for example, the extrusion speed is not set correctly, the machine will not produce the quantity of filament that has been determined, resulting in 3D printing problems.

Slic3r Configuration

For the manufacturing process to work optimally, not only must the 3D printer be correctly calibrated, but also the configuration parameters must be correct. Below you’ll find an overview of the various configuration parameters including for printing, filaments and the printer itself.

Print Settings

We let’s take a closer look at the general print configuration, which consists of layer height and the perimeters. The layer height represents the thickness of each extruded layer and is influenced by the desired resolution and printing speed. In general, it can be said that a lower layer height results in better print quality. However, the smaller the layer, the longer the printing time. The perimeters are the limits of each layer. It can be a fixed value for all layers or follow a more adaptive algorithm.

3D printing settings

You will also be able to choose the infill parameters, i.e. material used inside the model. The infill also serves as a support for the surfaces. Slic3r usually adds it automatically, but there are different infill patterns and other parameters to choose from. These affect, for example, the printing speed and strength of the printed model. There are also options related to the support material, which ensures that the protruding parts of the model are well-supported. These are generated automatically, but the density can be determined.

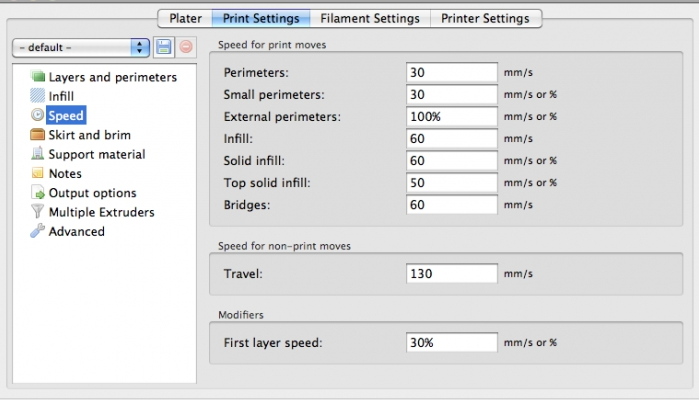

Another group of parameters is speed. These can be divided into sizes, fillings and support material. With this selection, Slic3r adjusts the extrusion speed according to the other parameters specified by the user.

Filament Settings

Filament settings are used less frequently. One reason for their use could be a new filament spool, for example. The software will fill in the values in the filament settings. However, you have the option of adapting or updating them. The values concern diameter, flow and temperature settings. In addition, you can enter optional information on the density and cost of the filament. In this way, Slic3r can help calculate the weight and manufacturing cost.

Photo Credit: Slic3r

Print Settings

The printer configuration is the least updated, unless Slic3r is used on several printers. Slic3r is compatible with dual-extrusion 3D printers. For example, some parts of a model need to be printed in different colors or with different materials. To inform Slic3r of the correct positioning of the extruders, a combination of printer parameters must be defined. Another important scenario is connectivity. The user can set up USB printing in the printer parameters. It is also possible to set up a serial connection, as well as remote connection and printing via the cloud using systems such as Octoprint or Duet.

Last but not least, Slic3r is equipped with an interesting feature for better thermal management of your prints. In fact, it can regulate both fan and print speed to give each layer the time it needs to cool properly before moving on to the next. A system that will prevent many errors and defects!

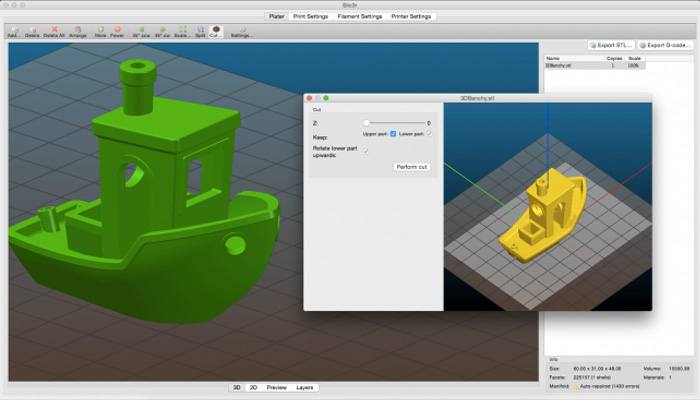

A 3D-printed model in two colors via Slic3r (photo credits: Slic3r)

What do you think of Slic3r? Have you ever used this slicer? Let us know in a comment below or on our Facebook and Twitter pages what you think! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!