U. S. Marine Corps is Investing in 3D Printing Innovation

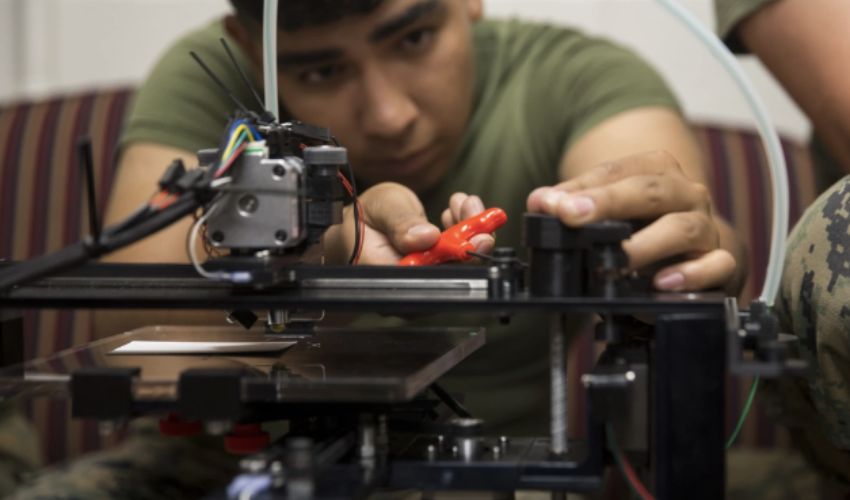

Within the field of additive manufacturing the various branches of the United States military have often been at the forefront of incorporating 3D printed devices and manufacturing techniques into their literal and figurative arsenals. From military buildings to naval ship construction and to the frontlines of combat, the military 3D printing sector is quickly growing into a multi-billion dollar industry. Most recently, the United States Marine Corps has issued a report highlighting the role of the Marine Corps Systems Command Advanced Manufacturing Systems (AMS) team in tackling the issues of supply and logistics effectiveness through additive manufacturing.

The USMC has been looking into the multitudinous applications of 3D printing as it places higher strategic importance on additive manufacturing in its new restructuring plan, Force Design, which refocuses the Armed Forces branch on potential threats and conflict scenarios in the Pacific where the Corps will require a “fully-integrated logistics enterprise” capable of supporting “multi-domain and distributed operations in contested environments”, as stated in their guidance document. Overall, the goal of this restructuring is to ensure that soldiers have access to top-of-the-line equipment and replacement parts without the added stress of long supply lines and geological obstacles.

The USMC has previously been involved with various AM projects including 3D printed concrete structures. (Photo credits: ICON)

3D Printing On-Demand Battlefield Supplies

Matt Audette, a program analyst for the Advanced Manufacturing Systems team, is confident about the potential difference that 3D printed parts can make in the field stating, “In a nutshell, additive manufacturing is a game-changer for the Marine Corps. It allows us to repair equipment and innovate solutions right on the frontline. With its smaller footprint and easy-to-use technology, we can construct essential components right on the battlefield, making us nimbler and more responsive in any combat scenario.”

Audette’s sentiments are part of the idealistic drive towards additive manufacturing that exists within the Marines AMS team. Indeed, AMS team lead Robert Davies’ stance illustrates the no-nonsense attitude that 3D printing can offer in terms of practical solutions when he said, “Parts break—that’s the reality of the battlefield. You used to have two simple choices: bring the parts or order the parts. Our advanced manufacturing solutions rewrite that playbook. Now, we can actually manufacture essential components right in the combat zone. When something breaks, a call is made: ‘We need a component.’ No more ‘We forgot it’ or ‘It’ll take months to arrive.’ We contact our machinists and within a couple of hours, we’re making and sending parts back up to the frontline.”

Ultimately, the use of 3D printers allows for greater mobility and customization for every need according to the mission-specific parameters. The uses for such technology stretch from medical supplies to vehicle parts and beyond. The benefits are not only visible in the reduced travel time and weight of the printed objects but also in the training and readiness of the users, who need significantly less training and specialization to operate a 3D printer compared to a traditional CNC or welding device.

The AMS team has been clear in their promotion of 3D printing as a means to an end, but they have been equally clear that additive manufacturing is set to complement traditional manufacturing, not replace it. As AMS team lead Davies reiterates, “We’re not here to mass-produce hundreds of components in an hour—that’s for dedicated facilities. What we offer is the ability to produce a limited number of key components on-site when they’re urgently needed.” For more information about the USMC and their AMS team, you can read more HERE.

Photo credits: Rachaelanne Woodward

What do you think of the Marine Corps’ AMS team? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Justin Updegraff