Superfici Talks Using 3D Printing for the Shipbuilding Industry

Among the industrial sectors currently reaping the benefits of additive manufacturing is the maritime industry. High standards, high surface quality, attention to detail, durable materials and customized design are just some of the sector’s requirements that 3D printing can meet, acting as a viable and sometimes necessary alternative to traditional production methods. Why and how can 3D printing be applied to the maritime sector? To find out more, we spoke with Superfici, an Italian company that is one of the first to install fully 3D printed parts on board ships. Paolo Nazzaro, CEO and co-founder, answered our questions.

3DN: Could you introduce yourself?

Hello, my name is Paolo Nazzaro and I’m one of the founding partners of Superfici, along with Davide Telleschi and Guido Zannoni. I’m a nautical designer with a PhD in nautical and sustainable product design. Since 2015, I’ve been an adjunct professor at the Nautical and Marine Design degree at the University of Genoa. My connection with 3D printing was born in 2010 from an experience I had during an internship with a company that develops diving equipment. On this occasion, I had the opportunity to create several prototypes with one of the first professional 3D printers installed in the company.

The founders of Superfici

3DN: What is Superfici’s mission?

Superfici was born in 2016 in Liguria, from the idea of introducing additive manufacturing to the shipbuilding sector. The challenge is to bring innovation to a world notoriously linked to traditional, artisanal manufacturing. Superfici responds to the high demand for the production of highly detailed models in this sector. This led to an in-depth study of materials and surface treatment. The development of this process has provided the necessary know-how to be able to supply today various components that are installed directly on board boats of various sizes. Today, Superfici is a complete specialist in 3D services for the maritime industry.

3DN: Why did you opt for additive manufacturing?

The naval sector is a world of small quantities, but with a high degree of customization and stylistic evolution. The constant search for new constructive proposals and complex shapes makes it a fertile sector for the introduction of additive manufacturing. The trend among shipyards is to differentiate themselves from their competitors by offering distinctive features, which are often hampered by the difficulty of construction and the high cost of producing components. 3D printing is therefore becoming a viable option, while having to cope with the high surface quality required.

3DN: What 3D printing processes and materials does Superfici use?

We mainly use fused deposition modeling (FDM) and resin 3D printing. Superfici currently has a fleet of 15 3D printers of various sizes. As far as materials are concerned, we have an agreement with a manufacturer in northern Italy who produces thermopolymers under our own brand name. The materials we mainly use are ABS, ASA and PETG. Our direct relationship with the manufacturer enables us to guarantee a very high level of quality.

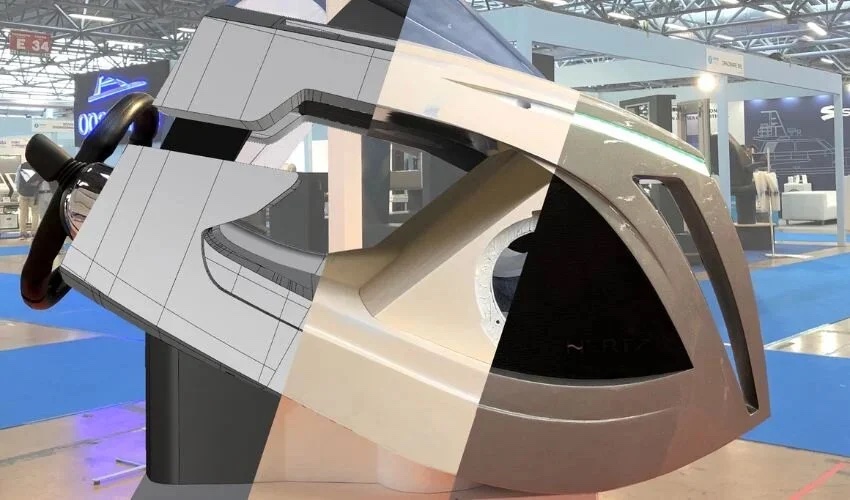

The first control cabin for a 30m Amer 94′ motor yacht, fully 3D printed by Superfici in 2018

3DN: How do you see 3D printing evolving in the maritime sector?

3D printing can meet the diverse needs of construction sites and designers. The trend is towards the production of larger and larger articulated parts. Another possibility is to produce molds for boat building. Today, the large number of obsolete molds poses a real problem of disposal and storage. The possibility of creating them by additive manufacturing with thermoplastic materials could bring many benefits to the industry.

3DN: What are Superfici’s most outstanding projects?

We’ve completed a number of projects over the years, including the first 3D-printed dashboard mounted on a yacht at the San Remo Amer shipyard. There’s also the development of a dashboard for SACS inflatable boats, entirely designed to take advantage of the full potential of additive manufacturing. Finally, we present the first 3D-printed steering wheel with a multi-functional display integrated into the center, created using generative design.

A 3D-printed steering wheel

We’re also working on several fronts to bring new ideas to shipyards, and to continue introducing additive manufacturing into production. So there’s no shortage of projects. Superfici is constantly evolving, and research and development are at the heart of the way we operate.

3DN: Any last words for our readers?

The main challenges stem from the diversity of the requests we receive, and the fact that the ever-increasing size of the parts implies a demanding production approach. In addition, our products have to withstand the external stresses of the marine environment, such as high temperatures, salt water and impact. The boat object itself is a complex body that moves and twists in different directions. All this requires a great deal of preliminary study and compliance with strict standards, which are essential in this work. You can find more information on the Superfici website HERE.

What do you think of Superfici? Is AM growing in prominence in the maritime industry? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Superfici