PA11 vs PA12: Which Nylon Should You Choose for 3D Printing?

Nylon, also known as polyamide (PA), is a group of thermoplastic polymers or plastics frequently used in 3D printing. Nylon is particularly appreciated for its ability to withstand high mechanical stress, and its resistance to heat, tearing and abrasion. This is why the material is often used in the manufacture of heavy-duty parts, for example in the automotive and aerospace industries, as well as in the medical sector.

3D printing uses many types of nylon, whose names vary according to the number of carbon atoms they contain. PA6 is most often used in FDM printing, while PA11 and PA12 are used in powder-based processes. Although PA11 and PA12 overlap in their areas of application, there are a number of differences between the two plastics. We therefore sought to compare the two materials and examine their respective properties, origins, printing requirements and, finally, applications and price categories.

Origin and Mechanical Properties

Polyamides are differentiated by nomenclature, and the number following the common code PA is a function of the number of carbon atoms. PA11 and PA12 therefore appear to be quite similar. Yet the two types of nylon differ in many respects, starting with their origin and manufacture.

PA12 is a thermoplastic, semi-crystalline and linear, obtained from natural gas or petroleum. Chemical processes are used to obtain laurin lactam, which is the starting molecule for the manufacture of PA12. In 1963, Chemische Werke Hüls AG first presented PA12 in collaboration with Emser Werke in Domat. Since then, the homopolymer, which consists of a single monomer component, has been used for many applications. Despite this, PA12 is increasingly at the heart of debates about its origin and environmental impact.

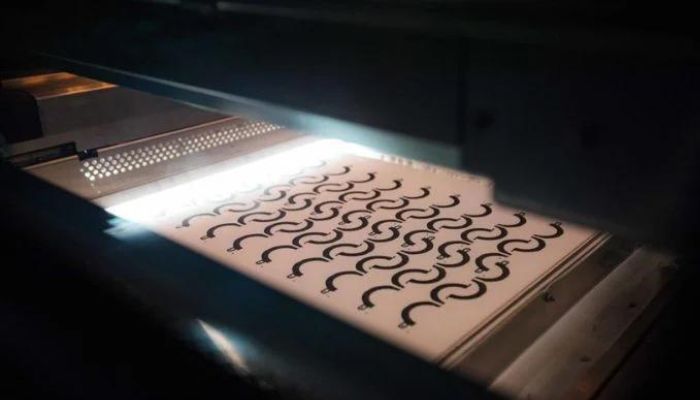

PA11 is obtained from castor oil and is therefore considered a more environmentally-friendly alternative to PA12 (photo credits: Jellypipe)

In search of greater durability and “greener” production, companies are turning to alternative materials with similar properties. This has contributed to the rise of PA11, as the origin of this polyamide is biological. PA11 is made from renewable raw materials, obtained from plant derivatives.

In most cases, castor oil is used, which in turn is obtained by pressing the seeds of the African miracle tree “Ricinus communis”. Castor oil is then converted into the amino acid 11-aminoundecanoic acid by synthesizing monomers. Subsequent polymerization of the monomers then gives rise to PA11.

The origin of PA11 thus resembles that of PA6, and is far removed from PA12. Although PA11 is considered a more sustainable alternative due to its biosourced origin, it is not biodegradable. Like other polyamides, it must be sorted in a specialized collection system before being processed for recycling.

Although the origins of PA11 and PA12 are very different, their mechanical properties are very similar, which is why they are often used in industry for similar purposes. PA11 and PA12 are considered to be extremely robust, strong and resistant, with convincing frictional-, wear- and chemical-resistance. PA12 is considered the lightest of all polyamide plastics, and is distinguished by its low concentration of amide groups. In addition, PA12 outperforms other polyamides in terms of low water absorption and density.

Although PA11 also absorbs relatively little water for a polyamide, it cannot compete with PA12 in this respect. Its advantages lie in its mechanical properties, which surpass those of PA12. PA11 is highly ductile and has excellent impact resistance. It is highly resistant to abrasion and fatigue, and PA11 parts boast higher isotropy. It withstands temperatures of up to 190°C, even though permanent temperatures range from -40°C to 125°C. Finished PA11 parts are both strong and flexible, durable and have an opaque matte surface. The same is true of PA12 parts. In both cases, the parts can be colored.

PA 12 (white) is the lightest type of nylon, while PA 11 (grey) has better mechanical properties. (photo credits: Jellypipe)

In terms of operating temperature, PA 12 fares less well than PA 11, because while it can withstand the extreme range of -50°C – 150°C, its continuous operating temperature is only 50-80°C. Like PA 11, it is also highly resistant to abrasion and fatigue. It is resistant to fats, oils, solvents, alkalis and salt solutions, making parts made from PA 12 highly wear-resistant and easy to weld and bond. Moreoever, PA 12 is not only the lightest polyamide, it is also the most resistant to stress cracking.

Although the impact resistance of PA12 is very good, it cannot quite match that of PA11. In direct comparison with PA11, PA 12 is also not quite up to scratch in terms of strength and hardness. This is why PA12 is often reinforced with additives such as glass or carbon fibers, to compensate for this shortcoming.

Both materials are generally compatible with fabrics, and parts made from them are suitable for contact with human skin. It’s worth mentioning, however, that some manufacturers’ PA12 can be used for parts that will come into contact with food, which is not always the case with PA11. There are, however, PA11 powders, such as APC-Tec’s PA11 Blue, which are FDA-cleared for food contact.

3D Printing Using PA11 and PA12

In 3D printing, PA is mainly used in filament and powder form. It is also possible to find PA resin for the SLA process, which mimics the properties of PA thermoplastics. The most used filament filament for nylon is PA6. It is also available to a limited extent as a powder.

Powder-based processes, on the other hand, primarily use PA11 and PA12. This is due to the thermoplastic properties of the material, as nylon can be shaped or joined particularly well using heat. These processes include Selective Laser Sintering (SLS), Multi Jet Fusion, Selective Absorption Fusion (SAF) and High Speed Sintering (HSS). They are characterized by high productivity, and the powder not used for parts can be recycled to a certain extent.

The MJF process (photo credits: Hubs)

PA12 tends to be used more often in additive manufacturing than PA11, both because of its earlier availability and its lower melting point. PA12 melts at 175-180° (depending on the manufacturer), whereas PA11 only melts at around 200°. These differences in melting temperature also explain why powders cannot be mixed together for the same print. Powder processing is a challenge for these 3D printing processes, although most manufacturers offer specific Build Unit solutions for each material.

Post-Processing

Whichever process you choose for printing with PA11 and PA12, post-processing is an essential step and applies to both PA11 and PA12 parts. There are therefore no differences between the materials in this respect, as some post-processing steps are mandatory for both, while others are optional for both.

Regardless of whether the components are made of PA11 or PA12, the first step is depowdering, in which the parts are removed from the powder cake and the powder is extracted from all sides. This can then be recycled to a certain extent in a new printing process. Various processes then allow extended cleaning of the parts, as some residual powder still adheres to the parts, and an improved surface finish.

Examples of post-processing methods include water jet, air jet and bead blasting, as well as chemical smoothing and drum polishing. In a further step, it is also possible to paint or dye the PA11 and PA12 parts.

An important step in all powder-based processes is post-processing (photo credits: Protiq)

PA11 and PA12 Applications

Both materials belong to the same group of plastics and can be found in a multitude of applications in the 3D printing process. This understandably leads to some overlap when it comes to the fields where they are used.

In the medical field, PA11 and PA12 powders are used as long as they have been determined to be biocompatible by the manufacturer. They are used in the manufacture of prostheses, orthoses, medical devices and medical appliances. In the medical field, however, PA11 is more appreciated for its biocompatibility and flexibility than PA12, which is generally stronger.

PA11 and PA12 are often used for prosthetics and orthotics (photo credits: EOS)

Both materials are also used in the automotive industry. PA11 is popular for vehicle prototyping parts, but also for serial production. Due to its resistance to impact and chemicals, it is also used for the manufacture of vehicle parts in the event of a collision, both internally (PA11 does not crack) and externally, for gaskets, engine components and coatings, for example. PA12 is also used in automotive 3D printing, i.e. for vehicle construction, particularly for precision hoses and tubes, including pressure- and impact-resistant fuel lines.

In aeronautics, PA11 is used in 3D printing because of its impact resistance and lightness, such as fairings and internal structural parts for aircraft. PA12 is also ideal for the manufacture of precision hoses and tubes – particularly for pressure- and impact-resistant fuel lines. Furthermore, in both the automotive and aerospace sectors, PA11 is appreciated, unlike PA12, for the lighter parts it produces and its contribution to energy efficiency, while PA12’s advantages lie in its rigidity and hardness for parts requiring greater strength.

The sports industry also uses both materials: PA11 for its abrasion-resistance, e.g. for ski linings and cleat soles, and for its superior flexibility. PA12 is used for winter sports equipment, such as alpine and cross-country ski boots and ski bindings, thanks to its particular mechanical resistance at low temperatures.

PA11 and PA12 are also used in sports (photo credits: Prodways/Salomon)

Both materials are used in mechanical engineering, electrical engineering and electronics, as well as in the packaging industry. Here, PA11 is particularly appreciated for its longevity and PA12 for its high toughness.

PA12 is used in the manufacture of precision hoses and tubes, particularly for pressure- and impact-resistant fuel lines, as well as for drive elements in wet environments or underwater transmission parts – where high dimensional accuracy is required – and for mechanical engineering components such as hinges and gears, as well as insulating films.

Meanwhile, in electrical engineering and electronics, PA11 is used as an insulating and protective material for cables, connectors and the housings of electronic devices. Furthermore, due to its particularly long service life, it is generally well-suited for highly technical applications.

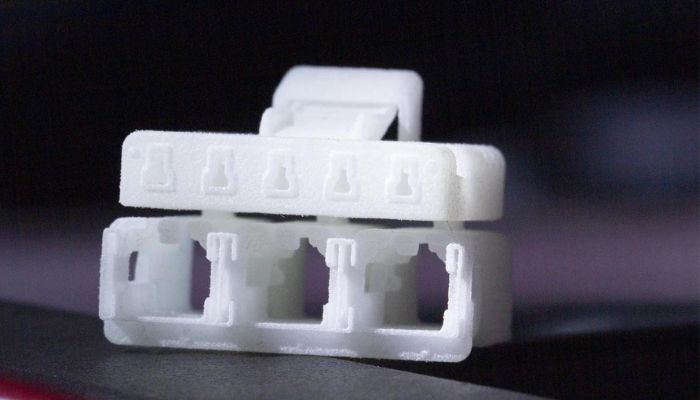

A nylon connector (photo credits: EOS)

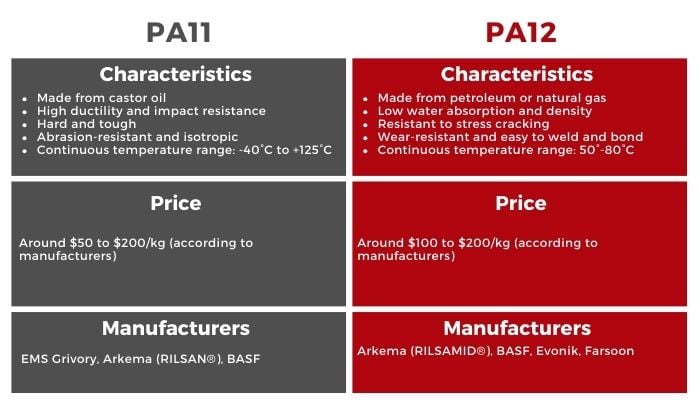

PA11 and PA12 Manufacturers and Prices

Generally speaking, PA12 is generally more expensive than PA11, as demand for PA11 is currently still low. PA11 can be purchased from some manufacturers for as little as $50/kg, but from others for $200/kg. Price variations for the same type of powder depend on whether it is standard or reinforced. Comparing the prices of finished parts made from the two different materials, it is easy to see that mass-produced parts made from PA11 are considerably cheaper than those made from PA12, by around 30% depending on the quantity produced. On the other hand, for the manufacture of single parts, it is worthwhile, from a cost point of view, to use PA12.

Both materials are available from a wide variety of manufacturers. Among the best-known PA11 manufacturers are EMS-Grivory and the French Arkema group, which sells PA11 under the name RILSAN® PA11. Arkema also offers PA12, formerly under the same name as PA11, but now under the name RILSAMID® to distinguish it more clearly. PA12 is also often sold on the market under the name VESTAMID® or VESTOSINT®. BASF also offers PA12 and PA11 in powder form. Additionally, PA12 is also available from manufacturers working in 3D printing such as Evonik, as well as 3DSystems and Farsoon, who offer powders developed in collaboration with chemical companies, but who keep these material development partnerships confidential.

In addition to the invention of the more environmentally-friendly PA11 material, more and more efforts are being made by various manufacturers to make PA12 production more organic and greener. German equipment and materials supplier EOS, for example, offers PA12 as a high-performance alternative to the ABS or PA6 plastics favored in injection molding, and has steadily improved the efficiency of this material’s production – for example, by reducing the carbon footprint through the use of renewable energies.

There are also polyamide powders on the market to which Kevlar, carbon fibers or even glass beads have been added. HP, for example, offers a thermoplastic with 40% glass beads and a high recycling rate. The material is available under the name HP 3D High Reusability PA12 Glass Beads. Recently, HP also announced the launch of a new PA12 powder developed in collaboration with Arkema, called HP 3D HR PA 12 S, which features a high reusability rate of up to 85%, helping to reduce waste.

Do you use PA11 or PA12 for additive manufacturing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.