The Department of Defense Is Using 3D Printing to Make Hypersonic Weapons

The U.S. Department of Defense has quite a history of using 3D printing, working to implement this technology in many of its new weapons and vehicle designs. An example of this is the agreement between Newport News Shipbuilding and General Dynamics Electric Boat (GDEB), where additive manufacturing is being integrated into the construction process of the Virginia class nuclear submarines to address supply chain shortages. In more exciting news in the field, according to Defense News, the Pentagon has announced that it wants to incorporate 3D printing into their Hypersonic Air-breathing Weapon Concept (HWAC). More specifically, the technologies will be used to make direct-flow air-jet engines which are used in everything from aircraft to missiles, and are unique in that they are capable of exceeding speeds such as mach 24 (or more than 18,400 mph/29,000 kph).

According to Keith DeVries, deputy director of the Office of the Secretary of Defense’s Manufacturing Technology Program, additive manufacturing will be useful in the development of new systems by enabling the rapid creation of complex components. Thanks to advancements in the technologies, now “these manufacturing techniques create objects from high-entropy metals that are particularly strong and stand up to wear and tear, using lasers to melt metals that can withstand high temperatures and allowing more complex shapes to be crafted.”

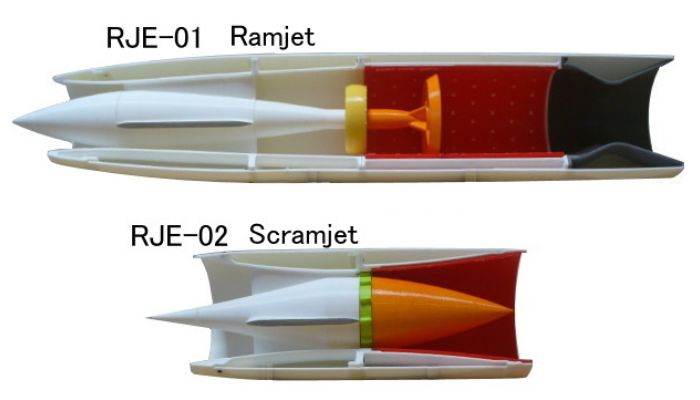

Differences between the U.S. Army’s traditional Ramjet engines and the new Scramjet engines manufactured with 3D printing (photo credits: Cults3D)

Notably, Devries notes that the technologies will be used in creating Scramjet propulsion systems, fundamental systems for hypersonic engines that require complex chambers and are very difficult to manufacture. Indeed, thanks to 3D printing, it seems that the perception of the manufacturing of these engines is changing. As mentioned above, these systems are now being implemented in missiles such as the Hypersonic Air-breathing Weapon Concept (HAWC). According to the deputy director of the Office of the Secretary of Defense’s Manufacturing Technology Program, additive manufacturing technology allows Scramjet components to be fabricated from metals at very high temperatures, without the need for complex welding as required by traditional methods.

3D printing technologies speed up the part manufacturing process, as complex welded joints created by traditional methods require expert approval to ensure their reliability. In contrast, this approval is not necessary for parts created using 3D printing. The reason behind this is that additive manufacturing produces the parts directly, without the need to create joints, avoiding time-consuming and tedious testing. Although the use of 3D printing technologies seemingly only brings advantages to manufacturing processes, Keith DeVries believes that the use of these technologies should be organic and limited. Additive manufacturing should only be used where it is needed and where it can maximize benefits.

The DOD has already shown its willingness to adopt different 3D printing processes in the US armed forces (photo credits: Defense Media Network)

What do you think of the use of 3D printing in the creation of these hypersonic weapons? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Defensenews