What Flame-Retardant Materials Are Available for 3D Printing?

As defined by Merriam-Webster, if a material is flame retardant, it is “made or treated so as to resist burning.” Or in simpler words, in contrast to flame resistance, where something can operate as normal within fire conditions, anything that is flame retardant actively prevents fires from spreading. And as you can guess, it’s incredibly important with the market for these materials estimated to be worth 8.63B in 2022 and with applications like furniture, textiles, electronics and even building materials. It also is gaining in importance within additive manufacturing for end-use parts where combustion is a risk, with an uptick in available flame-retardant 3D printing materials. We take a closer look at the different solutions, separated by filaments, resins and powders, on the market in the following list.

Filaments

High-Performance Flame-Retardant Materials

High-performance materials are a group of polymers capable of withstanding demanding environments, not only in terms of temperature, but also mechanical and chemical stress. These materials have complex thermal profiles and are often used for industrial applications, mainly in the aerospace, automotive and rail sectors. They are generally inherently flame retardant.

Take for example PEEK, which belongs to the PAEK family and has a high flammability temperature, in addition to being mechanically and chemically highly resistant. There are many manufacturers of PEEK in filament form, including Victrex, Evonik, 3DXTech and others. Another example is PEKK, a flame-retardant material that does not emit toxic fumes. This polymer is highly resistant to wear and fluids. Finally, it’s hard not to mention PEI – or ULTEM – when we talk about PEEK and PEKK. This thermoplastic is also flame-retardant. In fact, ULTEM™ 9085 is certified for low fire, smoke and toxicity (FST) applications, and its flammability rating is UL 94 V-0.

Another high-performance material is PVDF (polyvinylidene fluoride), which is flame-retardant. It is renowned for its very high chemical resistance and low coefficient of friction – it is particularly popular in the production of nuts, screws, etc. Among manufacturers of filaments for additive manufacturing, Nanovia and Solvay offer PVDF.

Finally, we can conclude with PPSU which, in addition to its interesting thermal profile, is reputed to be extremely resistant to hydrolysis, water and impact. Forward AM, a BASF brand, offers a PPSU filament for 3D printing that is highly suitable for the aerospace industry.

Parts 3D printed with PPSU (photo credits: Zortrax)

Polycarbonate (PC)

Polycarbonate (PC) is a thermoplastic distinguished by its transparency, which is why it is known as a glass-like material. In addition to this distinctive feature, it is extremely robust, resistant to impact and abrasion, and has a mechanical strength of up to 140°C. It is inherently flame-retardant and can withstand repeated steam sterilization. Its resistance remains high even at temperatures as low as -20°C.

Polycarbonates are commonly used as filaments in 3D printing in a multitude of sectors, notably for prototyping. Their applications extend to the production of car headlights, building components, molded parts and translucent housings for electrical equipment. The first industrial polycarbonate was introduced to the market in 1958 by Bayer in Germany. Today, manufacturers such as Polymaker, Kimya and UltiMaker offer this material, reflecting its growing popularity and usefulness in many industrial and manufacturing fields.

Photo Credits: 3djake

Other Flame-Retardant Materials

Although widely used for their strength and versatility in 3D printing, ABS and polyamide (nylon), two popular thermoplastics, are not inherently flame-retardant. However, they can be made flame-retardant by modifying them and adding certain specific additives. On the market are flame-retardant ABS filaments such as 3DXTech’s Fire FR-ABS, made from high-quality flame-retardant ABS that is UL94 V-0 rated, meaning it offers excellent fire resistance. This type of filament is ideal for applications in sectors such as automotive or aerospace, as it features self-extinguishing characteristics.

Similarly, Nanovia’s PA Rail polyamide filament complies with non-flammability standards, being specially designed to meet the requirements of the rail sector. Composed of polyamide (nylon) and ceramic flame retardants, this filament ensures greater safety in the event of fire by preventing the spread of flames.

Photo Credits: Polyfab3D

Resins

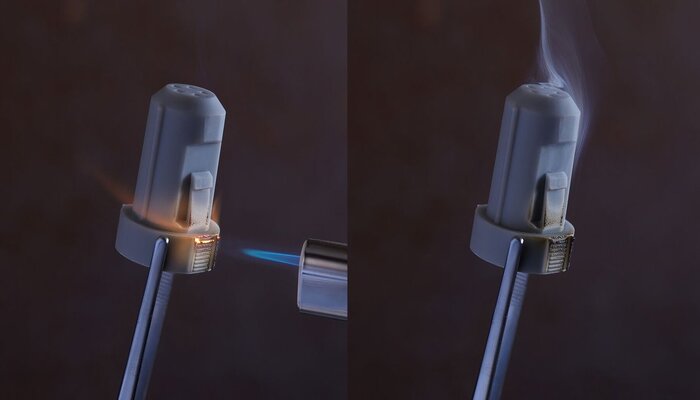

Formlabs’ Flame-Retardant Resin

Formlabs’ flame-retardant resin is an effective, low-cost solution for the manufacture of self-extinguishing parts using SLA 3D printing. Designed to withstand high temperatures without propagating flames in the event of a fire, this resin offers a suitable solution for industries subject to stringent standards, such as aerospace, aviation, electronics and medicine. By meeting UL 94 V-0 standards, it guarantees the production of safe, reliable parts, even in high-temperature industrial environments and close to ignition sources. After post-processing at 80°C for 120 minutes, these parts boast a Heat Deflection Temperature of 111°C at 0.45 MPa, guaranteeing their long-term strength and functionality.

Photo Credits: Formlabs

The Flame-Retardant EPX 86FR Material

EPX 86FR is a flame-retardant resin developed by the manufacturer Carbon. It is characterized by its toughness and resistance, offering a viable solution in demanding environments. With its self-extinguishing properties and BlueCard certification, it meets the most stringent fire safety standards. What’s more, EPX 86FR effectively resists high temperatures, thermal shock, chemicals and humidity variations without compromising its essential mechanical properties.

This resin is used in a variety of sectors where toughness, fire resistance, precision and surface quality are essential criteria. Furthermore, it is therefore widely used in industry, consumer goods and the automotive industry. Concrete examples of use include the manufacture of electronic housings and brackets, connectors and cable clamps.

Photo Credits: Carbon

Cubicure Evolution FR

Cubicure Evolution FR is the first material of its kind to achieve UL94 V0 classification, making it ideal for use in industries such as electronics and transportation. This material offers exceptional precision and surface quality, mimicking injection molding while maintaining heat resistance of up to 80°C. Developed using Cubicure’s Hot Lithography technology, Cubicure Evolution FR allows for precise 3D printing with resolutions of 10 µm.

As one of the very first flame-retardant photopolymer materials for resin 3D printing, Evolution FR presents an ideal option for spare parts production and functional prototypes. Its UL94 V0 classification ensures the self-extinguishing of flames within 10 seconds, a characteristic previously only achieved by materials used in the material extrusion and powder bed fusion processes. With its halogen-free composition, tensile strength of 34MPa, and ability to meet stringent safety standards, Cubicure Evolution FR offers an ideal option for industrial 3D printing, particularly in applications where flame retardancy is crucial.

Photo Credits: Cubicure

3955 HDT280 FST Resin

Developed by Loctite, 3955 HDT280 FST flame-retardant resin offers excellent physical and surface finishing properties. As a high-performance, halogen-free material meeting UL94-V0 standards, it is ideal for additive manufacturing of connectors, clips, sockets, electronic housings and interior parts for the most demanding industries. Thanks to its performance in vertical combustion tests, this resin is perfectly suited to FST aerospace standards, guaranteeing the safety and reliability of manufactured parts. Parts 3D printed with this resin, mainly using industrial DLP technology, will not deform in thermally harsh environments. This paves the way for its use in sectors such as aerospace and railways.

Powders

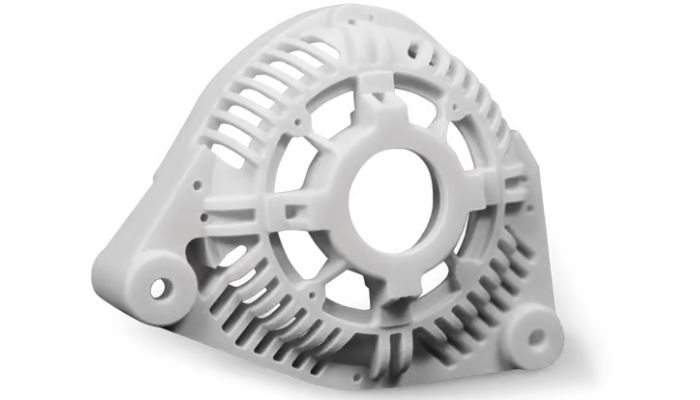

The Flame-Retardant Material PA 2210 FR

The highly flame-retardant polyamide powder PA 2210 FR is a high-performance, UL Blue Card-certified, and CS/FAR 25.853 compliant material suitable for various applications across multiple industries. This halogen-free and, therefore, non-toxic material exhibits advanced mechanical properties, with a tensile strength of 46 MPa and a flexural strength of 65 MPa. PA 2210 FR unlocks greater design freedom for complex parts, as its substantial build volume of 280 x 280 x 550 mm accommodates large components, while its layer thickness of 0.15 mm enables intricate details and precise features. Additionally, the material boasts a heat deflection temperature of 84°C, alongside several low flammability properties, making it highly suitable for environments where fire resistance is crucial, including industries such as construction, transportation, aerospace, and electronics.

Photo Credits: Materialise

DuraForm® FR 100 Flame-Retardant Material

DuraForm® FR 100, a flame-retardant thermoplastic from 3D Systems, is a solution developed to reduce smoke production and toxic by-products during combustion. UL94 V-0 compliant, this material meets the most stringent environmental standards for a wide range of consumer applications. Available in powder form, this material offers high toughness and good impact resistance, making it ideal for 3D printing, particularly selective laser sintering. DuraForm® FR 100 is specially designed to meet the needs of the aerospace, automotive and consumer goods industries, requiring flame protection and low smoke toxicity. Applications include aircraft cabins, electrical appliances, drones and enclosures.

Photo Credits: 3D Systems

What do you think of these flame-retardant, 3D printing materials? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Massivit 3D also have a Fire Retardant material Dimengel 20-FR

20-FR (DIM 20-FR) is the world’s first flame-retardant 3D printing thermoset gel for the production of large parts. It allows Massivit customers to meet essential flammability-related safety and performance requirements in accordance with industry regulations.

The polymer complies with the highest standard for flame-retardant materialsץ. Developed as a premium printing material for use with the Massivit 5000 industrial-grade 3D printer, this novel flame-retardant photo polymer serves a range of industries, including Automotive, Marine, Aerospace, Rail, and Scenic Fabrication.