The Role of Large Format Additive Manufacturing in Boat Building and Repair

In the maritime sector, additive manufacturing is becoming popular for the production of boats, whether to design custom parts, higher-performance components or entire models. In Greece, one of the countries where tourism is a key asset for the economy, the rental and sale of boats is booming and has become a sector with a significant amount of demand. Among the players in the market is Stefos Yacht Services, a company that maintains and repairs a large number of sailing and motor boats, often within strict deadlines. Recently, it has been using a large-format 3D printing solution to accelerate its manufacturing processes and offer its customers more tailored and efficient results. Accompanied by Lino3D, which prints the parts and ensures their post-processing, Stefos Yacht Services can rely on a real expertise and benefit from the advantages of XXL 3D printing.

Massivit3D is a manufacturer of large-format 3D printers that offers solutions with a very generous printing volume of 145 x 111 x 180 cm. Thus, the company addresses industries that need to produce large parts, all at high speeds. This is particularly interesting for the maritime industry, especially for repairing ships that need to get back on the water as soon as possible. For example, the manufacturer’s large-format machines can be used to produce instrument panels or radar masts. Thanks to its large build volume, the parts are manufactured in one go, without any assembly step, which facilitates their waterproofing and thus their duration in time. In addition, less waste is generated, reducing the environmental impact.

A piece 3D printed on a Massivit machine

That’s probably what prompted Stefos Yacht Services to rely on Massivit3D’s additive manufacturing solutions. Company founder and CEO Dimitris Stefos explained, “I started to look into the type of 3D printers we could use to meet our needs. We needed a solution that was large, fast and could be deployed easily. That’s when I met the Lino3D team who advised me and directed me to a Massivit3D machine.” For the time being, Lino3D is 3D printing the necessary parts for Stefos Yacht Services and, thanks to the company’s experience in shipbuilding and repair, is post-processing the part.

Additive manufacturing now allows the Greek company to produce prototypes that can be installed on boats so that the end customer can more easily project and validate the final part, rather than doing so on a CAD model. Through Lino3D, it also manufactures molds and finished parts. In any case, the technology offers significant time and cost savings. Dimitris Stefos says, “Today we use glass fiber reinforced plastic with polyester resin or epoxy resin for the final parts and wood or other materials for the pre-molding. This method, in addition to the time it takes and the excessive use of materials, has its limitations. The Massivit 3D printer, on the other hand, can produce any shape in any size for molding at least three times faster than before.”

Post-processing of a 3D printed part

One of the major challenges facing the marine industry is the resistance of parts to wear and tear over time and weather conditions that can degrade the condition of components. Additive manufacturing could be the answer, more specifically Massivit3D’s technology – producing parts that have been tested after periods of over two years at sea and withstanding harsh conditions without damage. 3D printing will allow the part in question to be produced again in record time, without having to go through the creation of an expensive and more environmentally damaging mold. And it remains to be seen what material developments the 3D printing industry has in store for us!

One thing is certain, Stefos Yacht Services can count on Lino3D’s expertise to develop innovative projects. Dimitris Stefos concludes, “Our collaboration continues in a friendly environment that allows me to have a panel of manufacturing solutions.” The boat specialist is expected to invest in its own Massivit 3D printer in the coming months.

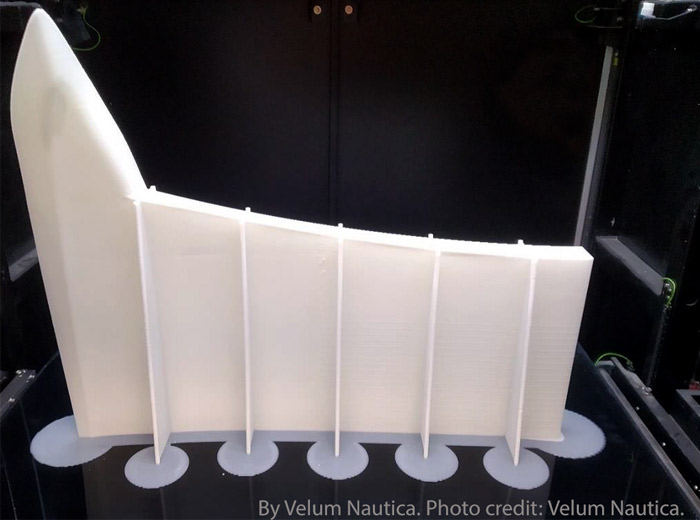

Yacht Hardtop Roof from 3D Printed Mold by Velum Nautica (photo credits: Velum Nautica)

For those interested in learning more, Lino3D will be present at Metstrade in Amsterdam from November 15-17, one of the largest events dedicated to the marine industry. It will be present at Massivit3D booth 12.603. Additionally, you can visit Lino3D’s website HERE to learn more about these different processes.

What do you think of the use of additive manufacturing in boat building and repair? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo: 3D printed mold by Velum Nautica for the roof of a boat (credits: Velum Nautica)