Massivit 3D, providing large format 3D printing solutions for visual communication

Advertising and retail are two segments that constantly seek to reinvent themselves by looking for new ways to be innovative. Now with 3D printing, brands can use the technology to integrate 3D printed pieces in their advertising for example. This is exactly the business opportunity Massivit 3D was able to grab by offering large-scale 3D printing solutions for visual communication applications. In record time, they are able to utilise their technology to create 3D printed props for movie sets or large pieces for an advertising campaign such as billboards. Now, they are even being approached by other industries for prototyping purposes. To learn more about the company and its technology, we interviewed Isabelle Marelly, Director of Marketing at Massivit 3D, who worked at Stratasys for 10 years before joining the company.

3DN: How did the idea of creating large format 3D printing solutions for visual communication applications come about?

Isabelle Marelly

The idea of creating large format 3D printing solutions came from our founder, Gershon Miller, who is a serial innovator, entrepreneur, and pioneering developer of large format digital printing (Scitex Vision) and 3D printing solutions (PolyJet technology from Stratasys). There was no existing 3D printer that could print at large scale and fast and there was a market need for this. In addition, visual communication market players, whether in advertising or retail, need to reinvent themselves. Print shops are facing tough competition and they need to differentiate themselves and find new services to offer to their customers.

Massivit 3D printing solutions can help PSPs by enabling them to allow the brands to reinvent themselves. The idea is to integrate 3D printed elements into billboards and to create POSs and Props in record time. Massivit 3D printing technology can produce big models because it can 3D print FAST: 35 cm (14”) per hour vertical speed, which is unique. In addition to the visual communication segment, our 3D printing solutions are increasingly used by scenic fabricators to produce props and movie sets. We have also been approached by the automotive segment for concept prototyping.

3DN: Can you tell us more about your 3D printing solution? What is the technology?

Existing AM technologies are based on 2 main technology families:

- Using solid materials – melting, depositing, and waiting for it to cool down and then start over with the next layer

- Using photopolymer liquids – jetting or curing in a vat using radiation

Both techniques are incredibly slow. Massivit 3D’s technology, Gel Dispensing Printing (GDP), uses a “half-baked” material and polymerizes it on the fly. The curing process is subsequently much faster and therefore doesn’t require support material. Massivit 3D’s GDP technology (hardware, software and material) enables Massivit 3D printing solutions to achieve radical speed.

3DN: What was Massivit 3D’s most innovative and challenging project?

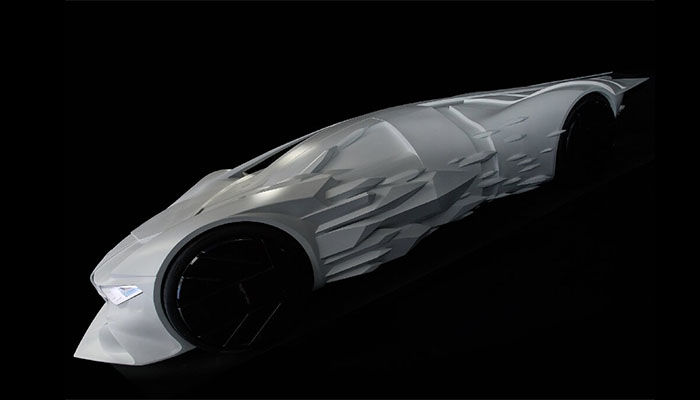

Our customers develop very exciting projects from props to POSs, window displays, and billboards with 3D printed elements. One of the most innovative projects so far was the “db car” that one of our France-based customers, Marie 3D, produced according to the design of a talented automotive designer called Takumi Yamamoto. This concept car was completely 3D printed in only 350 hours. Given the shape of the car, and the short production time, it wouldn’t have been possible to achieve with any other technology. The car was showcased at the famous Festival Automobile International in Paris in February 2019.

3D printed advertising piece

3DN: How do you see this segment of additive manufacturing evolving? Any predictions for the next 5 years?

Given the PSPs’ current market challenges the radical speed and success of our large format 3D printing solutions provide a concrete answer to these challenges. We predict a growth in the visual communication arena and believe that it will expand to additional segments. We are constantly investing in R&D in order to take our solutions to the next level

3DN: Any last words for our readers?

3D printing/Additive Manufacturing is all around us and has already proven to be a winning technology in other market segments such as aerospace, automotive, consumer goods and electronics, and healthcare. But it’s just the beginning. It’s a technology that has been disrupting markets and will continue to disrupt the way things are produced. We are just at the beginning of this journey and we believe that Massivit 3D will play a prominent role in evolving multiple industries.

3D printed running shoe

What do you think of Massivit 3D? Let us know in a comment below or on our Facebook and Twitter pages if the listing above was useful! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!