Cuttlefish-Inspired 3D Printed Body Armor to Redefine Safety

Researchers at San Diego State University are revolutionizing body armor design, taking inspiration from the resilience and adaptability of marine life. Spearheaded by Professor Yang Yang and his research team, this transformative approach integrates cutting-edge sensing capabilities into protective gear developed from stiff, yet highly durable composite. And it has been made possible through the use of 3D printing.

While marine life has previously been explored for inspiration in developing protective equipment, researchers at SDSU have focused their attention specifically on the durability of the cuttlefish. Renowned for its lightweight yet incredibly resilient properties, Professor Yang and his colleagues sought to emulate its structural makeup. As some species of cuttlefish can thrive under the immense pressure found 2,000 feet below the ocean’s surface, they have evolved a rigid, but lightweight microstructure within their shells to help them cope with these extreme conditions. This microstructure, known as wall-septa, enables cuttlefish to effectively absorb and dissipate energy to easily navigate this intense physical pressure.

Photo Credits: BBC Wildlife

Recognizing the potential of this capability, SDSU researchers identified a significant application in impact reduction. To mimic the structural efficiency of wall-septa, Yang and his team cultivated piezoelectric Rochelle salt crystals, integrating them with cuttlefish bone. In doing so, they have developed a novel composite material that dramatically absorbs impact force.

Practical Applications of SDSU’s 3D Printed Body Armor

The versatility of this advanced material extends across a wide array of industries, ranging from sports to defense, aerospace, and healthcare. One primary application of this composite is in helmets, which could revolutionize safety in sports and construction. These helmets not only offer superior impact protection but also feature real-time monitoring capabilities to alert medical personnel to any signs of distress experienced by the wearer. Similarly, in healthcare, customized exoskeletons like braces and kneepads could feature sensors to detect falls and provide in-depth data of the impact, enhancing safety for the elderly.

There are significant sustainability benefits as well, as the nature of 3D printed components enables easy and affordable maintenance and repair. Damaged parts of the 3D printed body armor can be swiftly replaced or restored by applying droplets of the composite to the broken areas, extending product lifespan and reducing waste— a stark contrast to conventional materials often ending up in landfills.

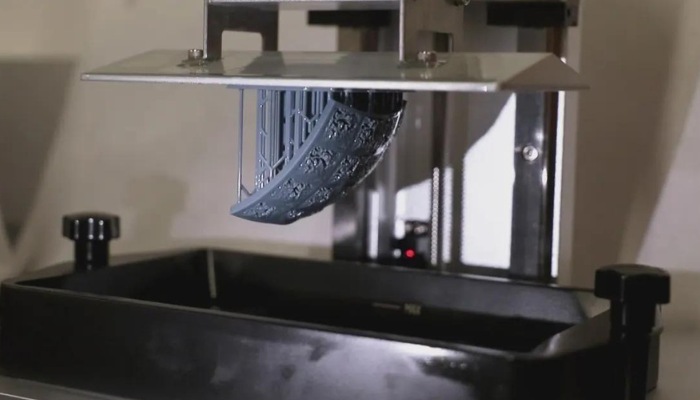

Cuttlefish-inspired composite. (Photo Credits: San Diego State University)

Explaining this process, Yann added, “When traditional ceramics break, it’s impossible to heal them in this way, creating a lot of waste. Our method, on the other hand, is reusable. The manufacturing process uses much less energy, and the overall price of the product is lower.”

As Professor Yang’s team continues to refine their body armor, collaborations with industry partners are underway. Since developing their body armor, they have partnered with 3D Systems, affiliated with the NFL, to advance research on how this composite and armor can be improved upon and implemented into the league. To learn more, click here.

What do you think of this cuttlefish-inspired 3D printed body armor? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: San Diego State University