US Navy Continues Onboard 3D Printing Initiative for Enhanced Self-Sufficiency

In further efforts towards operational self-reliance, the USS San Diego has leveraged the potential of additive manufacturing with the adoption of a Xerox ElemX 3D printer onboard. Housed within a dedicated 20-foot container within the ship’s main vehicle stowage area, the integration of the ElemX printer represents a significant milestone in self-sufficiency and improved onboard manufacturing capabilities for the US Navy’s deployed vessels.

The deployment of this printer reflects the recent yet ongoing trend within the US Navy towards fully embracing 3D printing technology, an essential aspect of modernizing its fleet and weaponry. It follows a strategic initiative to overhaul maintenance and shift how the Navy approaches part production. With this installation, crew members gain the capability to produce crucial components as needed, reducing reliance on external supply chains and enhancing operational flexibility. The utilization of the ElemX 3D printer is projected to drastically boost self-sufficiency in deployed vessels, as its ability to rapidly produce parts provides a crucial edge in critical scenarios.

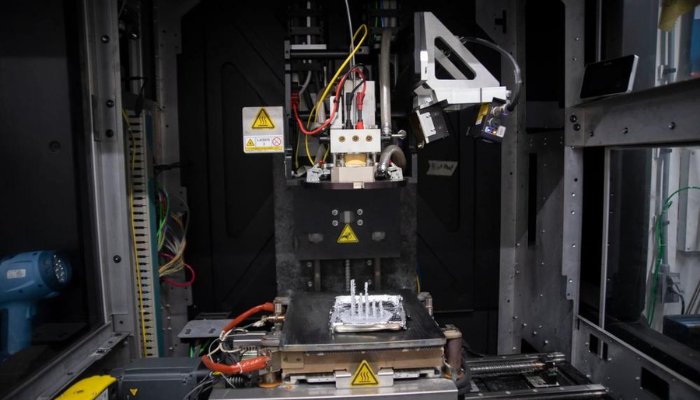

The Xerox ElemX 3D printer on board the USS San Diego.

Chief Warrant Officer Nicholas Garcia, a seasoned U.S. Marine, and Combat Cargo Officer emphasized 3D printing’s benefits for enhancing naval readiness, stating, “The purpose of the 3D printer is to establish an additive manufacturing capability aboard L-Class ships. This reinforces our ability as a naval force to implement self-help measures from an engineering casualty perspective and to confront future landing force maintenance requirements. These are necessary to project combat power during crisis response and contingency operations.”

The allure of on-site liquid metal printing lies in its ability to close the gap between traditional manufacturing processes and real-time operational needs. Aviation Boatswain’s Mate (Fuel) 1st Class Christopher Robertson praised the technology’s efficiency, citing instances where parts that took months to print can now be made within hours. “It can take a long time to receive certain parts in the Navy. But with something like this, we can turn six months of waiting for a part into a couple of hours.”

The adoption of 3D printing technology aboard has not only reduced logistical challenges but also cultivated a culture of innovation aboard the USS San Diego. Air department sailors, among the first to undergo training on the ElemX 3D printer, have fully embraced the opportunity, leveraging the technology to enhance their creativity and engineering skills. From crafting low-pressure air fittings to intricate toggle pins and sound-powered phone caps, producing parts on-demand has been a game-changer for USS San Diego crewmembers.

A 3D part created by the Xerox ElemX 3D printer.

Currently, plans are underway for the ElemX 3D printer to become a permanent capability on all L-Class ships. While the USS San Diego serves as the testing ground for the technology, there is a severe push for 3D printing to become a standard feature across the fleet soon, reshaping the landscape of maritime operations.

What do you think about the integration of an ElemX 3D printer on the USS San Diego? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: United States Navy