Should You Use SOLIDWORKS For 3D Printing?

In industrial sectors and product design, SOLIDWORKS is a CAD solution many rely on. The software has been around since the mid 90s and the latest figures estimate that there are around 9.3 million active users across 80 countries. It is based on parametric modeling and is primarily used to create 3D models and assemblies. SOLIDWORKS has also been adopted in the world of additive manufacturing, as it enables engineers to save their models in an STL format; the format needed for a 3D model to be processed by 3D printing software.

SOLIDWORKS was developed back in 1993 when John Hirschtick, a member of the MIT Blackjack Team, recruited a team of engineers to create the first accessible and affordable 3D modeling solution. At the time, AutoCAD, which had been released in 1989, was limited to the creation and editing of 2D geometry. Therefore, SOLIDWORKS was the first software to bring an accessible 3D modeling solution to the market. For many engineers, 3D modeling truly changed the way they could bring creations to life.

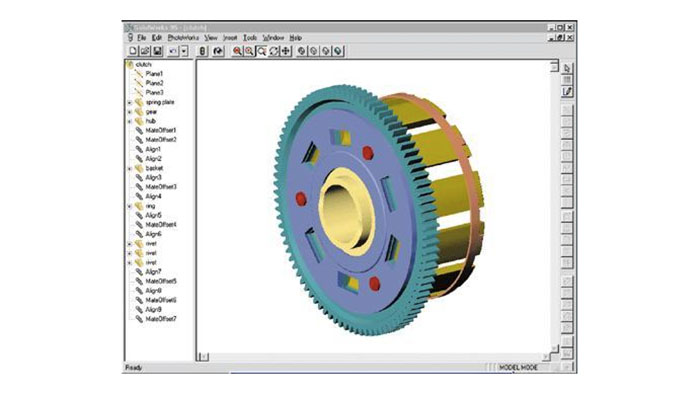

One of the first versions of the software

Soon enough the software became extremely popular and Dassault Systèmes decided to acquire it in 1997 for $320 million in stock. At the time, Dassault Systèmes was known for its CATIA solution, a product lifecycle management suite, which combines design, engineering, and manufacturing features used for automotive, aerospace and aeronautics. Essentially, SOLIDWORKS is a lighter version of CATIA.

Main Features of SOLIDWORKS

As mentioned, SOLIDWORKS is a CAD software based on parametric design. Parametric design is a process that clarifies the relationship between design intent and design response. One of the key features of parametric models is that attributes that are interlinked can automatically change their feature when one attribute is changed. This modeling process is great for projects with a lot of manufacturing requirements. 3D models can be created for high performance parts and assemblies used in sectors such as aerospace & defence or automotive.

For example, the very popular AutoCAD solution from Autodesk is primarily a 2D CAD software that caters to architects, home builders and civil engineers. Even though it is possible to create basic 3D surface and solid modeling with AutoCAD, it is not its key feature, and definitely not as easy as working on a parametric modeling software. This is the key benefit of SOLIDWORKS.

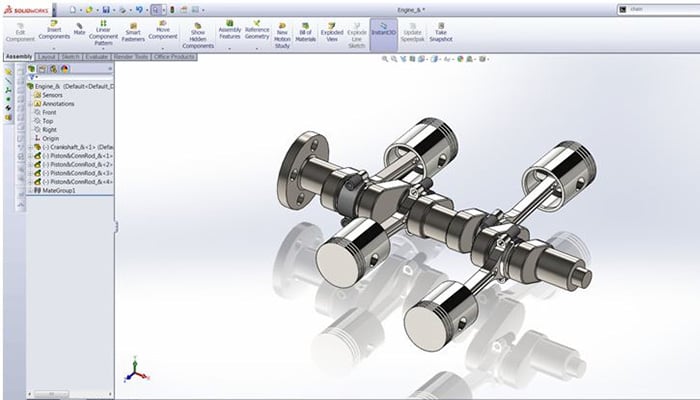

SOLIDWORKS is primarily used to model parts or assemblies (as is the case here)

SOLIDWORKS offers a comprehensive suite of tools tailored for various industrial applications, including simulation, rendering, and CAM (computer-aided manufacturing). With SOLIDWORKS, you can effortlessly craft solid models, manipulate surfaces, visualize wireframe models, and seamlessly generate 2D drawings from 3D solid models.

The 2022 Update

The latest update of SOLIDWORKS, dating from 2022, introduces several enhancements, offering various benefits. In terms of assembly performance and workflow efficiency, this update significantly reduces time constraints and enables seamless handling of larger assemblies. Additionally, opening a SOLIDWORKS drawing in Documentation mode now saves time regardless of your version or whether it was previously saved in that mode.

Other notable improvements include the ability to execute tasks concurrently, such as creating drawings on both sides of joint lines simultaneously and performing geometric symmetry on two planes concurrently, eliminating the need for duplication. There’s also model import, improved display performance, and other competitive edge enhancements thanks to 3DExperience’s extensive product portfolio. But these are just some of the latest additions to SOLIDWORKS. Here’s a video below, to find out all about the latest software update, and you can also view this PDF.

SOLIDWORKS Standard

SOLIDWORKS Standard will enable engineers and designers to create parametric parts, assemblies, and product drawings, as well as generate complex surfaces, flat sheet models, and structural welds. Thanks to its parametric design function, models are automatically updated in line with design changes. Conceptual design is also an important capability of the software, enabling design sections to be created, motors and forces to be applied to verify mechanism performance, and so on.

SOLIDWORKS Professional

SOLIDWORKS Professional builds on the capabilities of SOLIDWORKS Standard to increase design productivity with file management tools, advanced photo-realistic rendering, automated cost-elimination, design checking, and a part library.

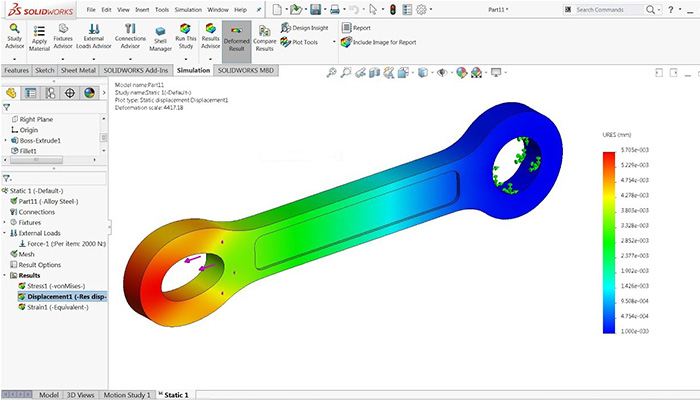

The software can offer powerful simulation tools.

SOLIDWORKS Premium

SOLIDWORKS Premium adds powerful simulation and design validation to the capabilities of SOLIDWORKS Professional, plus reverse engineering, and advanced wire and pipe routing functionality. ScanTo3D tools, available in SOLIDWORKS Premium, import mesh and point cloud data from which you can create surfaces and solid models.

Use for 3D printing

As mentioned, SOLIDWORKS can be used for additive manufacturing technologies because you can save your 3D model as an STL file. This is the format needed to transform the data from the model into G-code that a 3D printer can work with. However, this is not the only way in which SOLIDWORKS is suited for additive manufacturing projects. When designing for additive manufacturing, there will be many design considerations to take into account. Anything from distortions, warping, and breaking can occur, which means a 3D model must be adjusted accordingly.

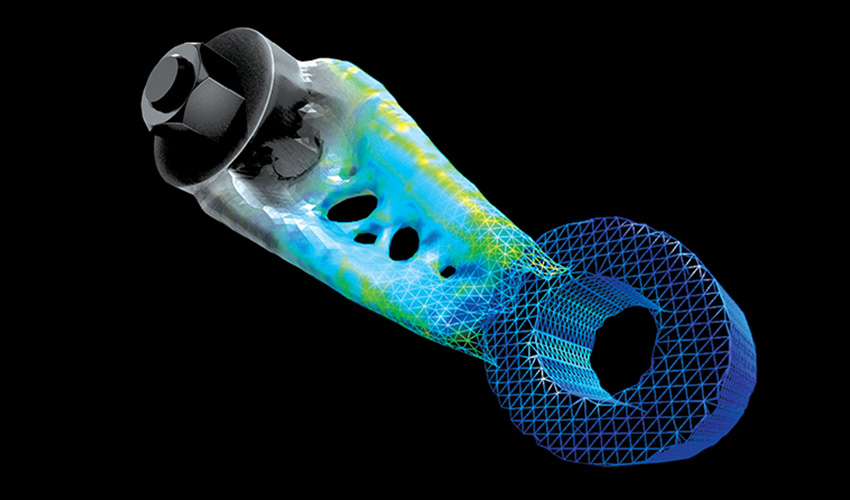

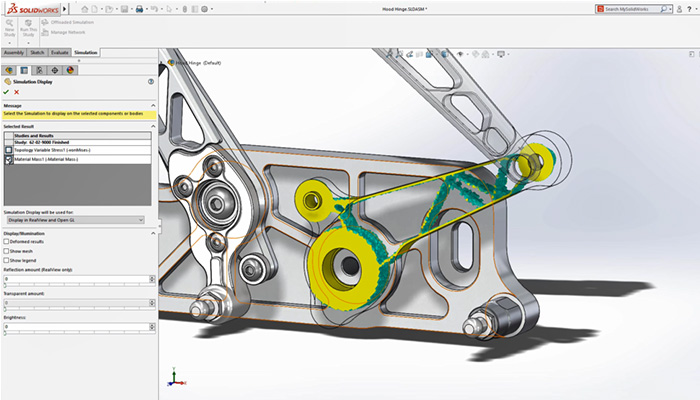

Topology Optimization is one of the design techniques possible on SOLIDWORKS

SOLIDWORKS has put in place tools that account for the special requirements of AM techniques, including support structures, and any distortion that can arise during printing. These features are extremely important, especially when working with expensive materials such as metals, where failed prints can be very costly. Finally, given the design freedom that 3D printing technologies allow, design techniques such as topology optimization can be applied to models. Another way to save material consumption and optimize a part! You can find more information HERE.

Do you use SOLIDWORKS? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

I would like to print a 3D model with Solidworks . starting with design and finish with 3D printing.

Thanks for sharing this Amazing information , Beautifully explained! If anyone wants to learn Solidworks training then I am here to suggest to you the best training institute for Solidworks i.e. ShapeMySkills Pvt Ltd. I did my Solidworks training course at ShapeMySkills Pvt Ltd and my experience was good. For more details you can visit website : https://shapemyskills.in/courses/solidworks/