3D Printing Innovates Neutron Science With “Frankenstein-Design” Collimator

In the industry of neutron science, unlocking the secrets of materials at the atomic level hinges on precise tools. Researchers at Oak Ridge National Laboratory (ORNL) have achieved a breakthrough in this domain by developing a novel approach to designing neutron collimators through 3D printing. These crucial components enable neutron collimation, a critical step in neutron scattering experiments, which allows scientists to study materials at the atomic scale. This new method leverages advanced 3D printing techniques to create highly precise, multi-part collimators, overcoming limitations encountered with traditional single-piece designs.

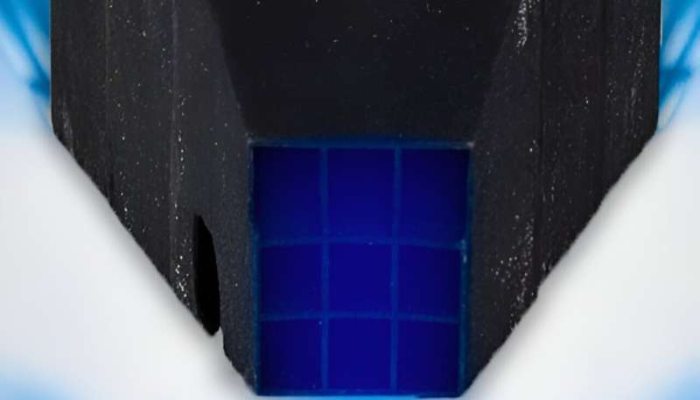

Traditionally, the challenge of crafting a one-piece collimator has been met with significant hurdles. However, a team of experts led by Fahima Islam, a neutron scientist at ORNL’s Spallation Neutron Source, discovered a novel solution through what they refer to as a “Frankenstein design” strategy. Rather than trying to produce one large monolithic structure, the team instead opted to 3D print multiple components that could then be easily assembled into a cohesive collimator.

The team behind the “Frankenstein Design” collimator: Fahima Islam, Bianca Haberl and Garrett Granroth

Collimators, similar in function to specialized funnels, are crucial in guiding and filtering neutrons towards detectors, thereby minimizing unwanted interference during experiments. Neutrons that fail to interact with the sample material or scatter off surfaces can distort data, requiring precise collimation to isolate the desired signals. A fully customizable, 3D printed collimator can offer the improved accuracy needed. Speaking on the effect of the unfiltered neutrons, Islam stated, “These unwanted neutrons produce undesirable signatures in the data, which is why we were working to produce a 3D printed collimator that could be custom designed to filter out these unwelcome background features during different types of neutron scattering experiments.”

To achieve this precision, the ORNL’s Manufacturing Demonstration Facility team employed binder jetting 3D printers. This approach proved a perfect fit as it offered both the flexibility and capability to create the intricate designs and complex shapes required for efficient collimation.

One significant challenge frequently encountered when producing a single-piece collimator is scaling up the part’s size while maintaining dimensional accuracy. In experiments involving high-pressure environments, the need for larger collimators becomes apparent to capture scattered neutrons effectively. However, traditional scaling methods prove inadequate, as larger collimators can produce less accurate data and are prone to breaking during experiments, prompting the team to explore 3D printing as an alternative avenue.

“Simply scaling up the print as one large part with continuous blades was clearly not feasible without further optimizing the printing process,” Garrett Granroth, a neutron scattering scientist at SNS, added. “The main reason for using smaller pieces is that the cracking observed in the single-part design was primarily due to variations in the material’s contraction rate during the curing and cooling process. By reducing their overall size, the individual parts cooled more uniformly.”

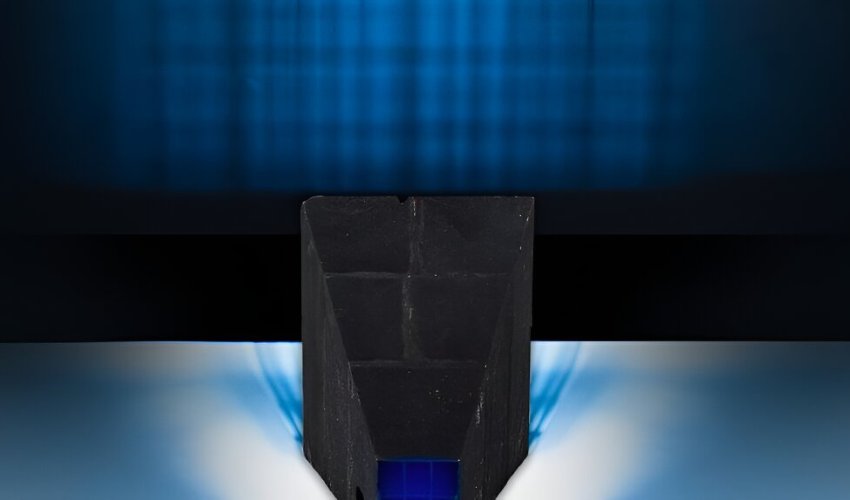

The collimator exhibits visible “scars” where the individual 3D printed parts are joined, which become apparent upon closer inspection.

The effectiveness of the new collimator design was evaluated at ORNL’s Spallation Neutron and Pressure beamline, a facility dedicated to high-pressure neutron experiments. According to the research team, the results were impressive, revealing a significant improvement in the data quality collected.

Looking ahead, Islam’s team plans to find additional ways to improve their design, such as stricter quality control during manufacturing and even more precise alignment techniques. By combining advanced modeling with cutting-edge 3D printing, the team believes this project will not only impact how instruments for neutron experiments are designed, but also push the boundaries of what is possible in neutron science. To learn more about this project, click here.

What do you think about this 3D printed collimator? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Oak Ridge National Laboratory