The Football Helmet from Vicis Enhanced with 3D Printing

Becoming a champion also means protecting yourself. From the NFL to the NHL, in a sports context where athlete safety is a central concern, technological advances are now turning to innovative solutions to protect players on the field. 3D printing is emerging as a promising option for revolutionizing the design of American football helmets, which is where company Vicis has made its play. The goal: to reduce the risks of head injury associated with the sport and keep players in the game.

Vicis brand helmets, which have consistently achieved excellent results in NFL tests over the years, have taken another step forward thanks to cutting-edge additive manufacturing technology. Case in point, the helmet is being worn by more and more players across the NFL, such as 49ers defensive lineman Nick Bosa and a string of high-profile QBs including Tua Tagovailoa, Derek Carr and Patrick Mahomes. Although its outward appearance seems ordinary, the inside of this helmet conceals 3D-printed pads, specifically designed to adapt to the shape of the head.

The Vicis Zero2-R Matrix ID Trench helmet features 3D-printed padding, customized to fit the shape of the player’s head perfectly.

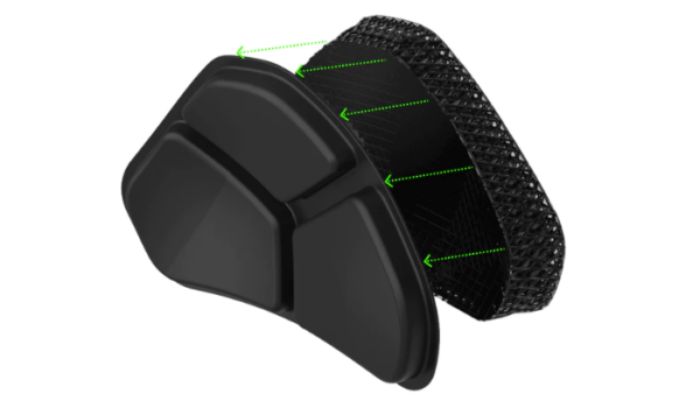

The Zero2-R Matrix ID Trench helmet from Vicis sets itself apart by incorporating customized padding manufactured using 3D printing, replacing the traditional foam padding that lines most football helmets. According to the results of laboratory tests, the use of this new technology can reduce the force of impact by up to 7% when a head comes into contact with the ground. The helmet’s padding consists of a series of lattice structures, carefully designed to combine lightness with the ability to absorb impact more effectively. These structures can be adapted not only to the shape of the player’s head but also to take into account his position on the pitch and the types of impact to which he is most likely to be exposed. Vicis improves its production by using the Carbon L1 3D printer, capable of producing padding for two helmets in a single print. This reduces printing time from eight down to just two hours per part, resulting in lower manufacturing costs. To guarantee a customized fit for each player, Vicis also relies on a 3D scanner called the Structure Sensor Pro.

The use of 3D-printed mesh padding isn’t a revolution in itself, as the Riddell brand launched the SpeedFlex Precision Diamond helmet in 2020. However, Vicis sets itself apart by taking this technology to the next level, beyond what has been done to date. First of all, they have chosen a standard high-performance helmet. Inside the helmet shell are six individual, interchangeable DLTA cushions, specially designed to deform on impact. These cushions can be easily replaced with Matrix ID cushions, creating a bespoke helmet offering maximum impact protection. This approach, in which 3D-printed components account for only 25% of the helmet, means lower manufacturing costs and shorter lead times. Which in turn, brings faster benefits to players on the field. To find out more about their helmets and 3D printed engineering, you can visit the Vicis website HERE.

The Vicis Zero2-R Matrix ID Trench helmet 3D printed padding.

What do you think of Vicis and their 3D printed football helmet? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Vicis