Breakthrough Could Enable At-Home 3D Printed Prosthetic Socket Manufacturing

3D printing has shown itself to be one of the most promising technologies in the medical sector thanks to its ability to create customizable solutions. This has made it especially popular for the creation of prosthetics and orthotics, which obviously need to be made to fit each individual person. Nevertheless, obstacles still remain, notably the fact that these 3D printed prosthetics still must be made in the hospital, making their use less widespread. But new research could change all that. Researchers from Loughborough University have announced a breakthrough in the creation of 3D printed prosthetic sockets with a fully digital design-to-manufacturing process which could ultimately allow lower limb prosthetic sockets to be printed in remote locations or even users’ homes.

Those of us not in the medical field may now be asking what exactly is a prosthetic socket? Well, as its name suggests, it is the device that joins the residual limb, or stump, to the prosthesis. For this reason, they are critical in ensuring a good fit for users, as poorly fitted ones can lead to stability and skin issues. The problem, however, is that, due to this, they are time- and labor-consuming to make. With each one requiring a high level of expertise and taking at least three to six weeks. Not only that, but they must be replaced regularly as they wear down quickly: about three to six months for adults and even more often for children.

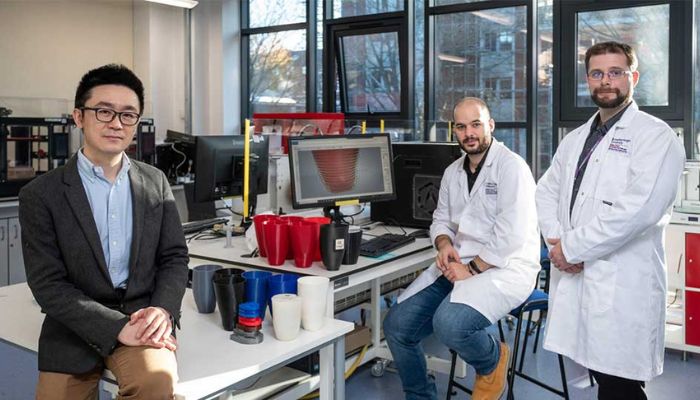

Dr. Simin Li and his team are working on creating 3D printed prosthetic limb sockets

But access can be difficult, especially in areas with less available healthcare, like in remote or poor communities. This is where the research from Loughborough University, led by Dr. Simin Li, a Senior Lecturer in Mechanics of Biomaterials in the School of Mechanical, Electrical and Manufacturing Engineering, comes in. He and his team have created a digital process that would allow for limb socket production through the use of 3D printing even outside of hospital settings.

Dr. Li explained the benefits of this “groundbreaking” process, commenting. “By using a fully digital design-to-manufacturing workflow and additive manufacturing – or ‘3D printing’ as it’s commonly known – our entire process for creating a socket is quantitative and iterative, therefore, highly customizable, repeatable, and efficient…The ultimate goal for this project is to make the design and manufacturing process easier and more accessible for both the healthcare professions and user so that one day the prosthetic socket can be manufactured in local community areas, hospitals and even in users’ homes on demand.”

Making Prosthetic Limb Sockets With 3D Printing

To make this work, Dr. Li has brought together a number of different technologies and coding for a fully-digital process. First, the limb in question needs to be scanned before a personalized design profile is created with CAD software. This file then can be imported into a 3D printer, for example a desktop FFF solution. Moreover, for users who may be less experienced in creating 3D models, they could scan their limb, send said scan to a healthcare expert to process remotely and then receive a customized design file. This would allow for printing of the socket wherever the user is, overcoming a number of geographical barriers, as well as making personalized medical devices more accessible than ever.

Though it may seem to be science fiction, the team actually has had significant success. Not only have they shown that they can customize designs to make them harder or softer depending on users’ needs, opening up 3D printed prosthetics to be used in everything from everyday walking to higher-intensity sports, but extensive testing has shown great results. Prototypes are able to bear loads ranging from 6,000 to 16,000 Newtons, equivalent to seven-to-20 times of body weight. An impressive feat for sure.

Dr Li concluded, “I hope to see this research one day benefiting lower limb prosthetic users worldwide and kick-start broader discussions about using 3D printing for medical devices and beyond. Currently, the entry barriers for accessing healthcare facilities, medical professionals, and 3D printing techniques in remote locations is too high. We believe our research will not only break down these barriers, but act as a catalyst for other exciting innovations that utilize 3D printing.” You can find out more on the dedicated website HERE.

What do you think of Dr. Li’s research and the ability to make 3D printed prosthetic sockets anywhere in the world? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Loughborough University