#3DExpress: Wilson’s 3D Printed Airless Gen1 Basketball Is Now Available

Once again, it is time for 3DExpress, the segment where we bring you short news stories from the week. This time, we talk to you first about Wilson and its 3D printed, airless basketball. Though we told you about the prototype last year, Wilson has officially announced that the so-called Airless Gen1 Basketball will be available in a limited release from February 16th, 2024. Exciting news for fans of both sports and 3D printing! Next up, Boeing has given a grant to fund an additive manufacturing space lab to advance 3D printing education for students. Learn as well about how OSF Healthcare is using 3D printing for better skin cancer treatment, Desktop Health’s new dental resin and the latest report on the rise of the polymer 3D printing material market. Have a great weekend and happy reading!

Wilson Releases 3D Printed Airless Gen1 Basketball

Last year, Wilson made waves with the announcement of its 3D printed, airless basketball prototype. Now this first-of-its-kind 3D printed basketball, named the Airless Gen1, is available! The basketball is exceptional due to its 3D printed polymer lattice structure which allows it to replicate the bounce, flight and feel of a traditional basketball (all without needing to inflate it). And there have been upgrades since we first saw the prototype, Wilson mentions new perforated channels, refined lattice and different colors (jet black, natural and brown) for this limited release.

Boeing Is Funding the Additive Manufacturing Space Lab

The importance of additive manufacturing in the aeronautics sector is certainly no secret. As one of the first industries to adopt 3D technologies, major aviation companies continue this trend as they continuously look into innovation in their fields. In the latest news, Boing has given a grant to the Space Foundation Discovery Center to establish an 826-square foot “Additive Manufacturing Space Lab.” The goal? To bridge the global skills gap in AM techniques by targeting students who are to be the next generation of engineers and innovators. The move shows the continued importance of 3D printing to Boeing.

The Space Foundation Discovery Center (photo credits: Space Foundation)

OSF Uses 3D Printing for Skin Cancer Treatment

Skin cancer is one of the most widespread cancers in the United States and around the world. However, despite this, treatment still has not been optimized as people with skin cancer on the surface of the skin can require large doses of radiotherapy as precise delivery is challenging. But that’s about to change. OSF Healthcare have announced their use of a 3D printed, patient-specific radiation bolus, which can help provide more effective, localized delivery of the treatment. The innovation further shows the benefits of combining healthcare with technology like 3D printing.

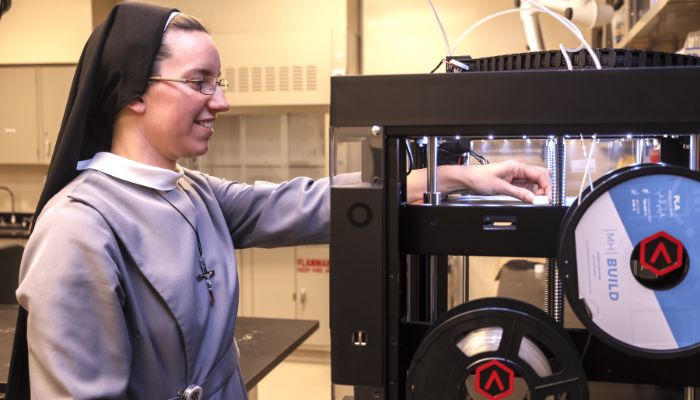

Sister Pieta from OSF Healthcare printing on one of the 3D printers (photo credits: OSF Healthcare)

Desktop Health Launches New Dental Resin Flexcera™ Base Ultra+

The global denture market is experiencing significant growth, with a value of $2.8 billion in 2023 and projected growth of 7.5 percent from 2024 to 2030, or nearly $4.6 billion. Resin 3D printing helps dentists and dental laboratories reduce labor and provide customized solutions that are faster and more convenient for patients. Desktop Health, the division of Desktop Metal dedicated to the medical industry, has just launched a new 3D-printed denture resin, Flexcera Base Ultra+, which joins the Flexcera line. It is a 3D-printable, light-curing resin used for fabricating the gingival component of removable full and partial dentures. The updated formulation is a nano-ceramic composite resin that provides a stronger and stiffer denture base, allowing thinner models to be fabricated for greater durability and comfort.

Photo Credits: Desktop Health

The 3D Printing Polymer Market on the Rise

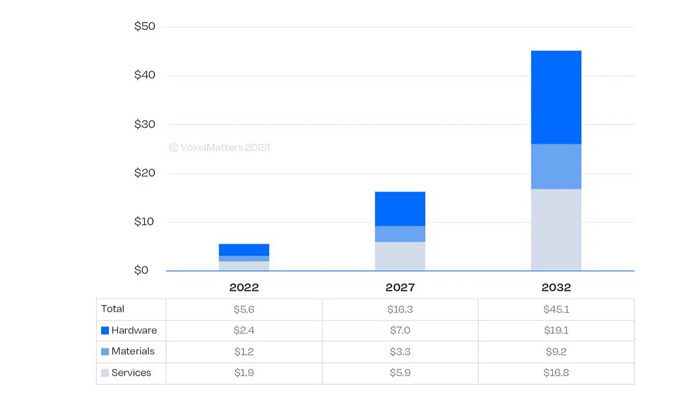

This week, VoxelMatters Research published a new study on the market for polymers in additive manufacturing. According to the study, the sector generated $5.6 billion in 2022, representing 19% growth over the previous year. Revenues are generated by the sale of hardware and materials, as well as by printing services. The report estimates this global market at $45 billion in 2032, representing growth of 23.3%. In fact, the 4 main sectors driving this growth are Industry, Consumer Goods, Automotive and Dental.

Additive manufacturing polymer market revenue forecasts by segment (in billions of dollars) (photo credits: VoxelMatters)

What do you think of Wilson’s Airless Gen1 basketball? What was your favorite in story in this week’s #3DExpress? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.