The EXT 800 Titan Pellet 3D Printer Expands Accessibility to Industrial Extrusion

Less than two weeks ago, RAPID + TCT, the largest additive manufacturing event in North America, took place. The event was a unique opportunity for many companies to showcase their latest innovations and products to the 3D printing community. Among them is the multinational 3D Systems, which unveiled the latest addition to its extrusion portfolio: the EXT 800 Titan Pellet. With more compact hardware and a lower required initial investment, this system enables wider adoption of the EXT industrial platform in both new and existing markets. All those attending RAPID + TCT had the opportunity to see this new machine from 3D Systems, along with the company’s entire portfolio of solutions at its booth.

As you may already know, in 2022 3D Systems entered into an agreement to acquire Titan Robotics. Dedicated to the development of large-format industrial 3D printers with hybrid toolhead configurations, Titan Robotics had a variety of pellet extrusion-based machines. With this acquisition, 3D Systems expanded the strength and breadth of its portfolio of polymer 3D printing solutions to address applications in new markets. Now, two years after this acquisition, they presented the EXT 800 Titan Pellet at RAPID + TCT. We took a closer look at the characteristics and functionalities of this new machine.

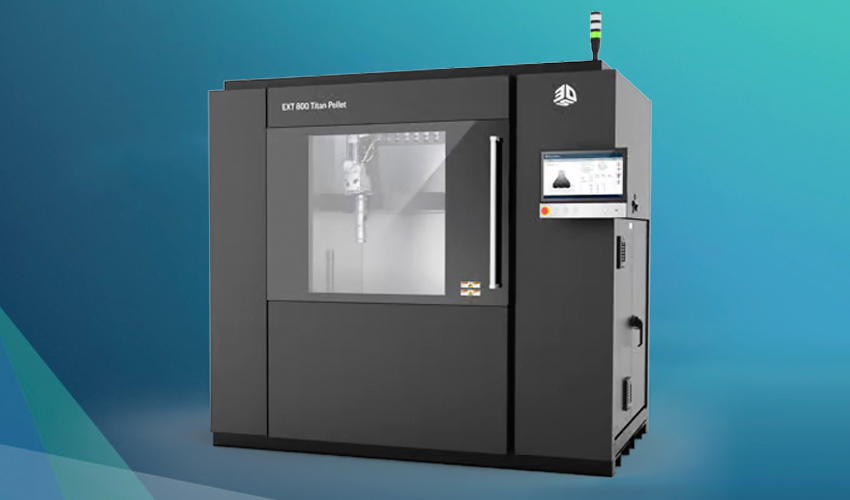

The EXT 800 Titan Pellet 3D printer is a pellet extrusion system (photo credits: 3D Systems)

Features of the EXT 800 Titan Pellet

With a build volume of 800 x 600 x 800 mm, the 3D printer uses the pellet extrusion technology developed by Titan Robotics. The company claims that this solution is up to 10 times faster than available filament systems using feedstocks up to 10 times less expensive, contributing to a faster return on investment (ROI). In addition, 3D Systems stresses that this 3D printer leverages all the benefits in terms of speed, reliability and efficiency of previous EXT Titan Pellet systems, but in a much more compact format and without the need for a high initial investment.

There are a number of advantages present in the EXT 800 Titan Pellet, for example industrial CNC controllers for reliable and repeatable production, the company’s proven pellet extrusion hardware and materials, and finally, a heated bed and chamber for higher part accuracy. This last point, related to the temperature of the chamber and build plate, is the reason why the machine is compatible with the use of high-temperature glass- and carbon-filled engineering materials, such as ABS, PC, Nylon, PEI and PEKK, as well as highly flexible TPEs and TPUs that could not be printed on filament-based machines. The system also includes a large front touch screen that offers an intuitive user experience.

The production-ready EXT 800 Titan Pellet features a single extrusion head, refined design and open material system to address a wide range of industrial applications efficiently and cost-effectively. Thus, many users and companies can turn to this 3D printer to manufacture functional prototypes, tooling, fixtures, sand casting patterns, thermoforming molds and final parts. In fact, it is intended for a variety of professional industries, including aerospace and defense, thermoforming, prosthetics, footwear and research.

The machine on display at RAPID + TCT 2024 (photo credits: 3Dnatives)

“With the addition of the EXT 800 Titan Pellet to our industry-leading family of pellet extrusion systems, we are able to bring this technology to a broader set of manufacturers to enhance their products and innovation,” says Rahul Kasat, Titan’s vice president of 3D Systems. “For manufacturers seeking speed and sustainability, our EXT Titan Pellet systems are a game-changer. They combine high-speed printing with cost-effective pellets, making the technology ideal for a wide range of applications.”

The development of the EXT 800 Titan Pellet has been carried out taking into account feedback from 3D Systems’ customers, with the aim of meeting their production needs. One of them is the possibility of creating smaller parts at a reasonable manufacturing cost. Thus, the new machine is designed for manufacturers who are looking for these advantages, but do not need the large manufacturing capacity of current systems.

“We believe the combination of high-speed, high-quality printing with a smaller footprint and lower upfront investment cost will make the EXT 800 Titan Pellet an attractive solution for a variety of industrial applications. This is yet one more example of how 3D Systems develops innovative solutions that empower our customers to stay ahead of the curve,” concludes Kasat. The EXT 800 Titan Pellet is available for immediate orders and delivery of the first printers is scheduled for the third quarter of 2024. More information about this machine can be found on the 3D Systems website here.

What do you think of the 3D Systems EXT 800 Titan Pellet 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: 3D Systems