3D Systems Receives FDA Clearance for 3D Printed VSP PEEK Cranial Implants

In the realm of cranial reconstruction, conventional methods have often relied on standardized or manually crafted implants, limiting customization and posing potential complications. However, in a breakthrough for personalized medicine, 3D Systems has recently secured FDA clearance for the world’s first 3D printed VSP PEEK Cranial Implant. This solution represents a significant leap forward in cranial reconstruction, and is expected to offer improved levels of patient-specific care.

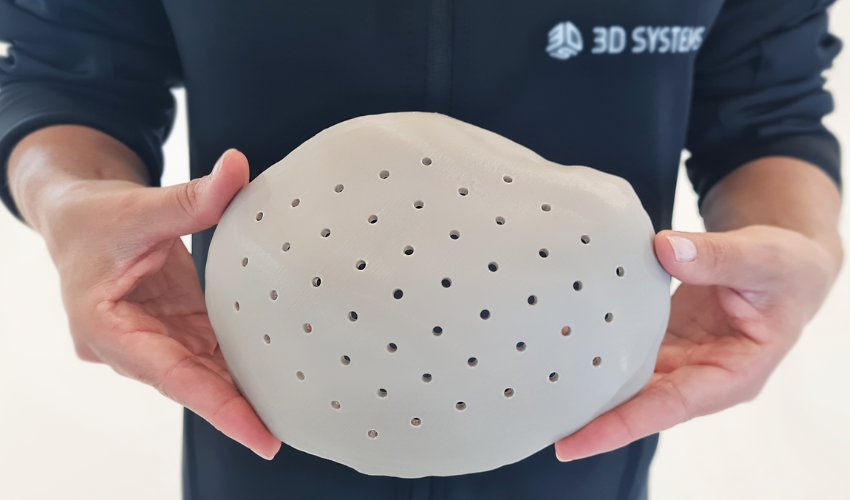

The VSP PEEK Cranial Implant offers a complete FDA-cleared workflow, integrating segmentation and 3D modeling software with the 3D Systems EST 220 MED 3D printer and Evonik VESTAKEEP i4 3DF PEEK material. Through 3D printing, this technology crafts patient-specific cranial implants using up to 85% less material than traditional machining methods, resulting in significant cost reductions and quicker production times.

PEEK Cranial Implant placed directly onto the top of the skull.

The benefits extend beyond cost-efficiency, reports 3D Systems. The printer’s cleanroom environment, paired with streamlined post-processing, allows for on-site production of these custom implants directly at hospitals. This eliminates logistical hurdles and potentially reduces wait times for patients in need. Notably, this innovative system has already seen success in Europe and the Middle East, with just under 40 successful cranioplasties performed in Switzerland, Austria, and Israel.

Dr. Johannes Pöppe, a leading surgeon at University Hospital Salzburg, highlighted the potential of the VSP PEEK cranial implants, stating, “This solution is revolutionizing the field. The combination of 3D Systems’ printing technology that is uniquely engineered for sterile environments and PEEK’s mechanical properties are helping surgeons push boundaries. Within our hospital, we have already completed several successful surgeries using these technologies. I believe the potential for customized PEEK cranial plates is significant to integrate 3D printing into routine clinical practice.”

The FDA clearance signifies a significant move forward for cranial implant surgery. Renowned for its exceptional mechanical properties mirroring human bone, this implant-grade polymer boasts a rich clinical history in medical device applications. With its high versatility, PEEK offers outstanding biocompatibility, resistance to bodily fluids, and stability across various temperatures, making it a prime candidate for diverse medical device applications.

Reflecting on the achievement of receiving FDA clearance, Dr. Gautam Gupta, Senior Vice President & General Manager of 3D Systems, stated, “Receiving FDA clearance for our VSP PEEK Cranial Implant solution is a significant milestone in our journey. . . With this FDA clearance, we are now able to bring VSP PEEK Cranial Implant to the U.S. — setting a new standard of excellence for these procedures. We are now looking to the next applications for this technology, which includes 3D-printed spine interbody fusion implants, carbon fiber-reinforced PEEK for plating applications in trauma and fixation, and bioresorbable polymers for large bone and craniomaxillofacial applications.”

Successful implantation surgery of the PEEK Cranial Implant.

As the landscape of medical technology continues to evolve, the market for cranial reconstruction will likely experience significant growth, with industry reports projecting market growth of $2 billion by 2030. The company anticipates that the combination of high demand and the benefits offered by 3D printing will drive widespread adoption of its PEEK Cranial Implants within the medical industry. To learn more about this project, click here.

What do you think of 3D Systems gaining FDA clearance for its 3D printed implants? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: 3D Systems