3D-Printed Scaffold Used in Treatment for Patient With Gunshot Wound

Sometimes it seems that the uses of 3D printing in the medical field are growing by the day. Beyond surgical planning and training, increasingly additive manufacturing is being used for implants and in surgical procedures to heal traumatic injuries. The latest case of this comes from the Hannover Medical School, Clinic for Trauma Surgery, where a customized, resorbable 3D-printed bone replacement scaffold, made by BellaSeno, was used to treat a third degree open infected fracture due caused by a gunshot injury.

Prior to this, BellaSeno, an ISO 13485-certifield clinical-stage medical device company, was perhaps best known for its regenerative implants. Its work in breast implants for women who have had to have mastectomies as a result of breast cancer is especially notable. Now the German company (which also has a subsidiary in Brisbane, Australia) has branched out into the fields of trauma and orthopedics with this latest case.

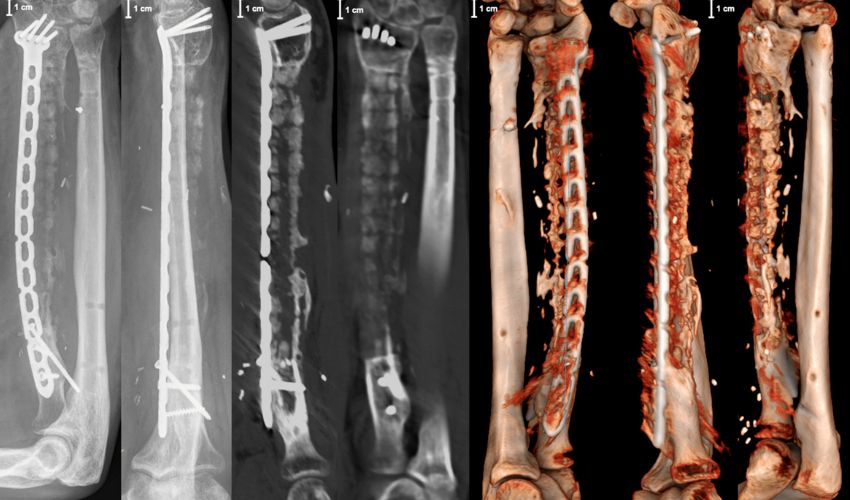

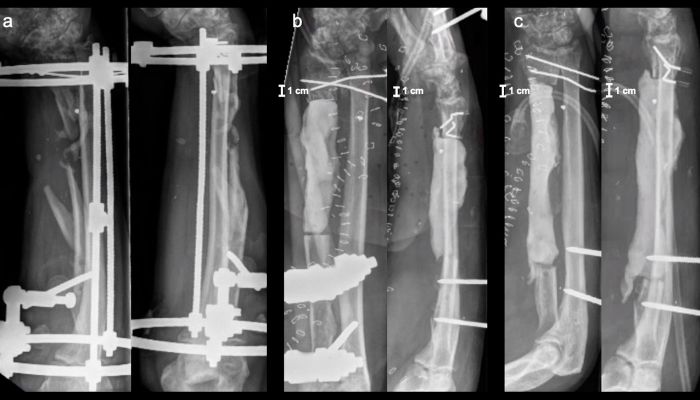

X-ray images (AP and lateral view) of the right forearm: (a) at the time of admission; (b) after 1st operation; and (c) before bone reconstructive surgery

Making a 3D-Printed Replacement Scaffold

Carried out in October 2023, the procedure in question was to reconstruct a 14 cm segmented bone defect of the radial shaft. This long section of bone spans from the neck to the radial tuberosity, a significant portion of the arm. Before treatment at Hannover Medical school, the patient had already undergone eleven surges to close the wound, but the fracture had only been stabilized by a ring fixator as the size of the injury posed a problem. The final stage was the integration of this bone replacement scaffold that was designed to reabsorb in into the body.

Prof. Dr. med. Philipp Mommsen, Managing Senior Physician, Clinic for Trauma Surgery at Hannover Medical School and lead author of the paper explains, “As the example of the 46-year-old patients demonstrates, sophisticated solutions to treat large bone defects are scarce. BellaSeno’s scaffold enabled us to conduct a new surgical technique for graft vascularization by embedding a vascular muscle arcade directly into a patient-specific, 3D-printed bioresorbable scaffold. This surgical procedure represents an innovative and promising approach for the restoration of extensive bone defects. As we see an increasing number of such catastrophic and very difficult to treat defects we are facing a rapidly growing medical need to reconstruct such injuries.”

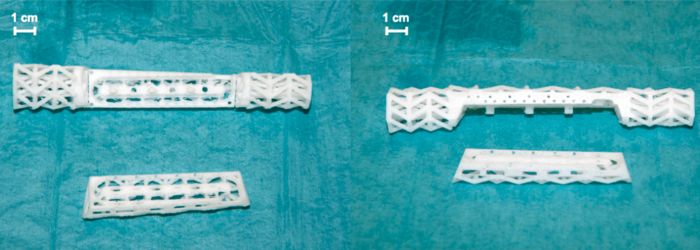

The 3D printed bone scaffold

As you can guess, the benefit of 3D printing in this case was that it could be customized precisely to the patient. To do this, BellaSeno used their AI-drive additive manufacturing facilities to create a 3D printed cage that perfectly matched the patient’s anatomy and could ensure a secure hold of the autologous bone graft, which was taken from the medullary cavity of the femoral bone, in the large void. It was made out Resomer®, a biodegradable polymer platform from Evonik, and design of the part was key in order to allow for proper internal vaculization by position an arterio-venous loop within the scaffold.

Indeed, it seems that the cage has both an inner and outer support frame and integrated a vascular pedicle which was place on the outer cage frame. Furthermore, the cage is expected to not just be totally bioresorbable but also has osteoconductive properties. This combination of the reconstruction of an extensive radial shaft bone injury while also ensuring immediate vascularization was seen as particularly important in the treatment.

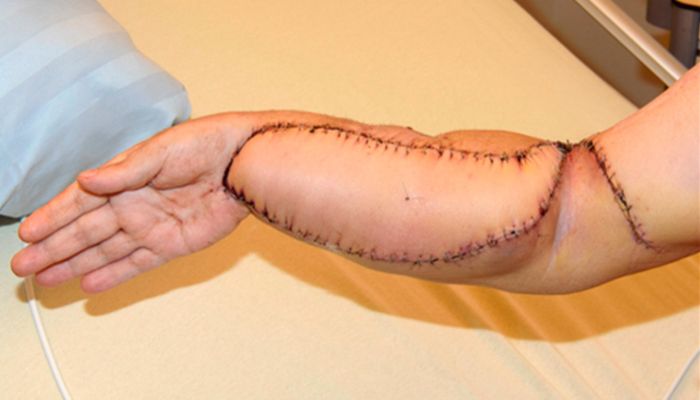

The best part? The surgery for the 3D-printed scaffold seems to have succeeded, at least according to a press release from BellaSeno. Three months after, the patient has shown signs of timely bony integration and has regained adequate elbow function with no signs of wound healing disorder or infection.

The arm after surgery

Dr. Mohit Chhaya, CEO of BellaSeno concludes, “This case study once again underlines the versatility of our technology. Almost any design request by a medical team can be fulfilled to optimize the patient’s treatment. The open structure of the scaffold enables vascularization which is crucial not only for proper bone healing but also to allow access of immune cells and anti-microbial drugs to prevent surgical site infections. We are currently working on next-generation bone scaffolds made of a composite of PCL and bio-active glass with anti-infective properties.” You can find out more in the case study, which was published in the Journal of Personalized Medicine HERE.

What do you think of the use of this 3D-printed scaffold to treat bone defects caused by a bullet? Where do you expect we’ll see the next innovations in 3D printing in healthcare? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Hannover Medical School and BellaSeno