3D Printing Applications in the Fight Against Breast Cancer

Being a woman is the biggest risk factor for developing breast cancer. Even though men are not immune to this type of cancer and around 1% are diagnosed with it every year, breast cancer was the most common cancer in women in 2022. According to the WHO, an average of one in twelve women will develop breast cancer during their lifetime. And this is global—even if the mortality rate is higher in developing countries than in highly developed regions. In 2022, 2.3 million women worldwide were diagnosed with breast cancer and 670,000 women died from it.

In breast cancer, abnormal breast cells grow uncontrollably and spread to the whole body if left untreated. Early detection and education about treatment options are crucial to reducing these alarming numbers. For this reason, October has been declared Breast Cancer Awareness Month and October 19th is World Breast Cancer Day. In October, we therefore find initiatives in all corners of the world to raise awareness, treatment and coping. In addition, more and more companies and research institutions are developing innovative ways to support women with the disease. Here, we find numerous projects and research approaches where 3D printing is used for breast cancer. Below, you can read about some current approaches in which 3D printing is used to overcome breast cancer.

CollPlant and Stratasys Regenerative Implants

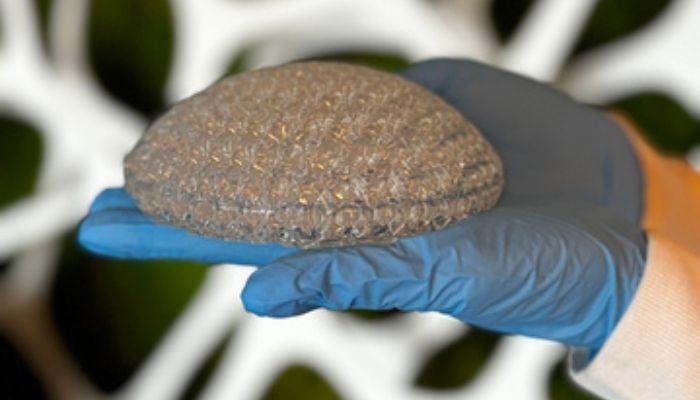

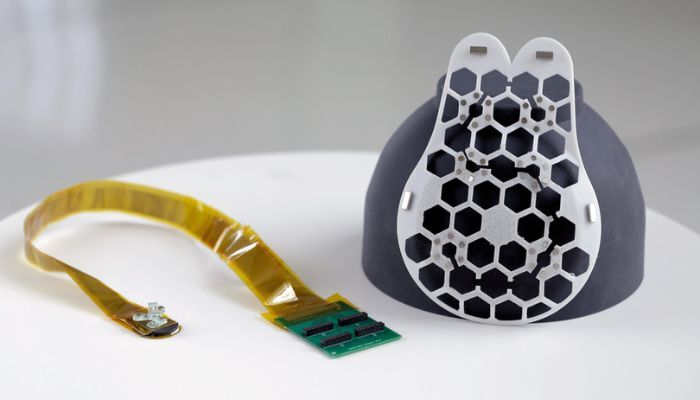

Often, many traditional breast reconstruction procedures rely on a limited supply of human cadaver or animal tissue. CollPlant’s innovative 3D bioprinting approach eliminates this supply barrier, allowing broader access to reconstruction for more patients. This year, CollPlant and Stratasys teamed up on a new preclinical study to produce regenerative breast implants. Combining Stratasys’ Origin system and CollPlant’s rh collagen biotin, the implants will be tested to regenerate natural breast tissue without triggering an immune response. CollPlant had already reported evidence of well-developed connective tissue and blood vessels in the 3D implant as well as tissue growth within it. However, the results of this collaboration will not be known until the second quarter of 2025.

Although the Stratasys Origin is not a bioprinter, the machine has been adapted to allow processing of rh collagen bioink (Photo credits: Stratasys)

Lattice Medical’s MATTISSE Bioprosthesis

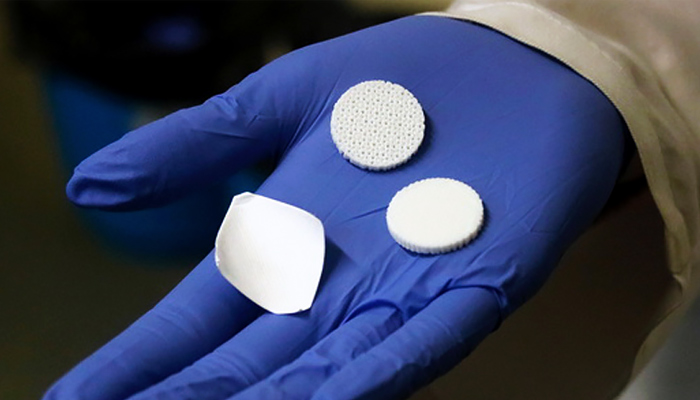

Lille-based Lattice Medical has consolidated its position as a leader in innovation after six years of research and the registration of 12 patents. The French company has developed MATTISSE, a breast bioprosthesis that combines 3D printing, advanced biomaterials and tissue engineering techniques. This innovative device not only provides the desired volume and shape, but also facilitates breast tissue regeneration. MATTISSE is made by the additive manufacturing of resorbable biomaterials, which allows the regeneration of autologous adipose tissue. Once implanted, the prosthesis integrates naturally into the body, allowing the tissue to regenerate over a period of six months, after which the bioprosthesis dissolves without leaving residues. To learn more about Lattice Medical’s activity and its use of 3D printing in the fight against breast cancer, don’t miss this exclusive interview:

Healshape Is Using 3D Printing for Natural, Resorbable Breast Prosthetics

Isolation of Aggressive Cancer Cells

A research group at the University of Girona succeeded in using 3D printing to isolate the cells that cause breast cancer in women. Specifically, they made tiny 3D matrices, called scaffolds, that reproduced the tissues and fibers of the human body. With the help of BCN3D Cura software and the Barcelona manufacturer’s Sigma 3D printer, they tested various parameters to create the most optimal models for the research. They made 10 copies of each configuration in order to see which geometry best separated the stem cells, which are the ones that cause relapses. By successfully isolating the stem cells of this subtype of cancer, the researchers will be able to study them better to find the biomarkers responsible for the tumors and be able to target them with drugs.

Photo Credits: University of Girona

BellaSeno Innovates with Resorbable 3D Implants for Breast Reconstruction

BellaSeno, a German pioneer in the 3D printing of medical implants, is developing resorbable implants for bone and soft tissue reconstruction, manufactured by 3D printing. At this year’s 93rd Annual Plastic Surgery Meeting in San Diego, BellaSeno presented preliminary results from its clinical trial. The data showed that its medical-grade polycaprolactone (mPCL) scaffolds deliver twice the breast volume retention compared with fat grafting alone. These scaffolds also demonstrated optimal safety, with no complications such as infection or necrosis. In this study, 19 patients received mPCL breast scaffolds filled with 50% autologous fat grafting, following removal of their silicone implants. Follow-up over 12 to 24 months revealed no major complications.

Next, BellaSeno plans to open a fully automated production plant in Australia in 2025 that will specialize in 3D printing medical implants. The plant will produce up to 100,000 custom-made breast scaffolds per year, offering customized solutions.

Photo credits: BellaSeno

The University of Limerick’s 3D-Printed, Bespoke Breast Prostheses

At the University of Limerick in Ireland, researchers have announced what they claim to be a ‘world first’: creating bespoke breast prostheses for women post-mastectomy using both 3D scanning and printing. Resulting from a collaboration between the Rapid Innovation Unit at the University of Limerick (UL), the Symptomatic Breast Care Unit at University Hospital Limerick (UHL) and the Mater Private Network’s Mid-Western Radiation Oncology Centre, the pilot service hopes to improve the quality of life for survivors of breast cancer. In essence, women who have undergone a complete mastectomy (full removal of one or two breasts) will have access to fully personalized prostheses that will be produced onsite at the point of care, perfectly matching the residual breast no matter shape or size. Though the researchers do not delve into which 3D printing technology was used, they do mention that the treatment hopes to address the lacking ‘one-size-fits-most’ approach that is the current standard. The project will aim to deliver tailored prosthesis solutions across Ireland.

The team behind the UL project (left to right): Emmajude Lyons, PhD Researcher, Rapid Innovation Unit, University of Limerick; Dr Lorraine Walsh, Consultant Radiation Oncologist, Mater Private Network Limerick; Mr. Chwanrow Baban, Consultant General and Oncoplastic Breast Surgeon, Symptomatic Breast Unit, University Hospital Limerick; and Dr Kevin J O’Sullivan, Senior Research Fellow, Rapid Innovation Unit (Photo credits: University of Limerick)

The 3D Printed Implant that Adapts to the Body and Releases Drugs

A group of researchers at Queen’s University Belfast (QUB), with the aim of treating breast cancer efficiently, have created 3D printed implants thanks to Tinkercad and the Cellink Bio X 3D bioprinter. These customized implants have been manufactured with intelligent materials capable of changing their shape and characteristics. Thanks to the use of this technology, the implants can be programmed, and controlled by external stimuli such as temperature or humidity, to improve their adaptation to each patient. The benefits of using 4D printing in the implant are not merely aesthetic, they are also capable of gradually releasing drugs in very precise locations. This type of chemotherapy drug (doxorubicin or DOX), helps the patient to prevent the recurrence of cancer cells.

Photo credits: Queen’s University Belfast

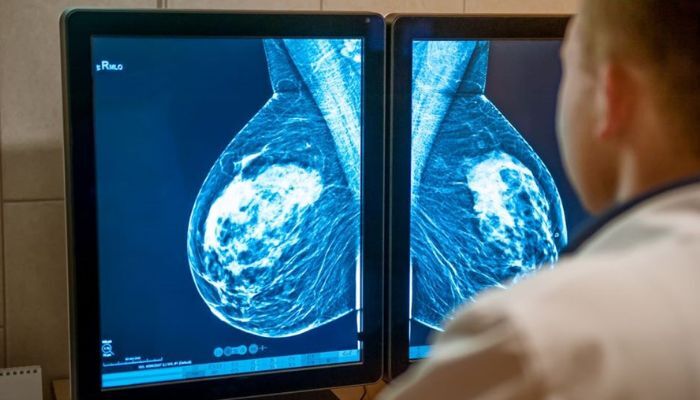

3D-Printed Ultrasound Device Designed to Fight Gap Cancers

A research team at MIT has created a 3D-printed device that promises to help in the fight against breast cancer. The purpose of this ultrasound device is to provide early detection of this type of cancer. Something that worries both doctors and patients is interval cancers. We are talking about tumors that develop rapidly between regular mammography appointments, which are also more aggressive than those detected routinely. Canan Dagdeviren, lead author of the study, points out that his aim was to design a device that would allow more frequent screening of high-risk individuals. The so-called cUSBr-Patch consists of a 3D printed patch with openings, which provides an in-depth scan and image from different angles of the breasts. This device was created using a 3D printer Prusa i3 MK3S+ using TPU and PLA, is attached to the bra and allows this type of scan from home in order to combat interval cancers.

Photo credits: MIT

ONEBra

ONEBra is a young Italian company that has devised a solution for women who have had to undergo a mastectomy following breast cancer. Often, in fact, the asymmetry of the breasts that results from this surgery causes additional psychological difficulties for patients. ONEBra has therefore devised customized 3D-printable bra cups that fit the woman’s physiology. Through scanning done at home, the client can scan her body and send the images to the company, which then 3D prints the customized bra cups and ships them to the patient’s home. Through the use of additive manufacturing, the product is shipped in a short time and with complete respect for the person’s privacy.

ONEBra 3D printed cups are made with HP MJF technology in TPU. (Photo credits: ONEBra)

ReConstruct Bio

ReConstruct Bio is a company started by the Wyss Institute at Harvard University. Using the 3D bioprinting technology SWIFT devised by the Wyss Institute, ReConstruct Bio focuses on breast reconstruction and augmentation for women who have undergone mastectomy. The team has developed BioImplant, a bioengineered tissue created from patients’ own cells. This tissue printed with the SWIFT technique is vascularized to ensure immediate integration with the patient’s blood supply. In addition, by using the patient’s own cells, it minimizes rejection and other complications. This technique, according to the company, produces better results than synthetic breast implants and can be used for breast reconstruction and augmentation, as well as other reconstructive or cosmetic procedures.

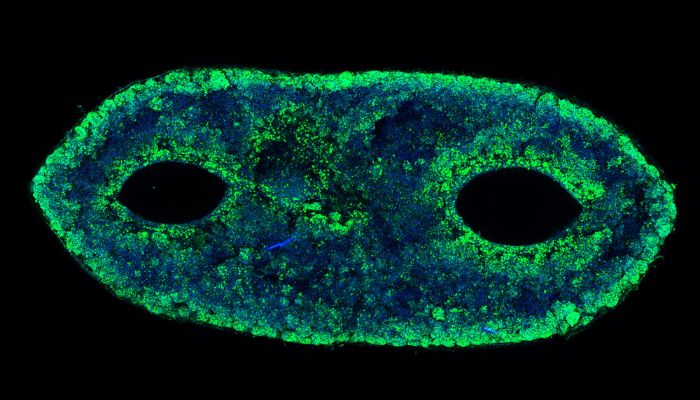

A microscopic image of vascular channels within adipose tissue that has been bioprinted and perfused in vitro for four days. (Photo credits: Wyss Institute – Harvard University)

Cellbricks Prints Biological Implants

Many women who have to have breast cancer surgically removed opt for an implant after the procedure. Until now, these have usually been made of silicone. However, silicone implants carry the risk of the body encapsulating them and the implants have to be removed after some time. To create a better alternative to silicone implants, the Berlin start-up Cellbricks is working on the development of implants made from human tissue. With its proprietary biofabrication technology, Cellbricks is able to print an implant from human cells – sometimes directly from the patient. The key to success lies in the bio-ink, the stereolithographic multi-material bio-printing process, but also in the software and process technology.

Cellbricks breast implant (Photo credits: Cellbricks)

3D Printed Mini-Tumors to Improve Cancer Immunotherapy

Researchers at the Leiden Academic Center for Drug Research have 3D printed mini-tumors within an environment that closely mimics human tissue to assess the efficacy of cancer immunotherapies. These immunotherapies include enhanced T-cells, which are specialized immune cells that can attack cancer cells, and bispecific antibodies, which help the T-cell locate and destroy the cancer cell more effectively. By 3D printing mini tumors, the researchers can have a more realistic model of the immunotherapy interactions, as opposed to traditional immunotherapy testing done in a Petri dish. Their 3D printed mini tumors, which they embed in collagen gel, more accurately mimic the human body.

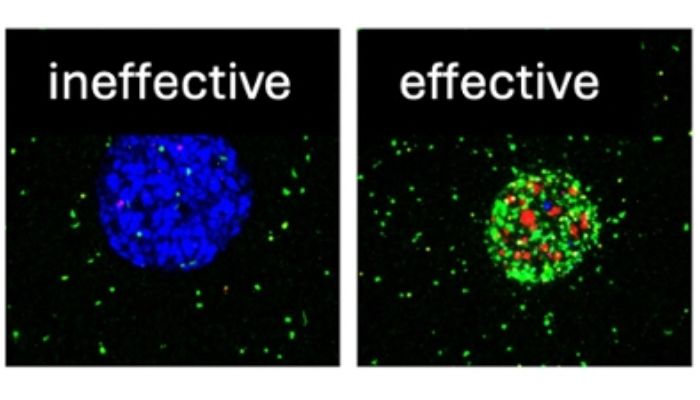

The team uses a 3D bioprinter to inject tumor cells into the gel, creating small 3D tumors, which grow and invade the gel as they do in the body. Then, the T-cells are added and monitored with automated microscopes. The testing method has already proven successful, and the researchers have been able to disseminate which antibodies are effective. They even collaborated with Reno Debets’ immunology lab at Erasmus Medical Center in Rotterdam to test new receptors for triple-negative breast cancer therapy.

The tumor on the left has inactive antibodies, and the tumor on the right has active antibodies. The green indicates T-cell recruitment, and the red indicates tumor killing. (Photo credits: Liao et al. (2024))

The University of East Anglia and Its Approach to Breast Reconstruction

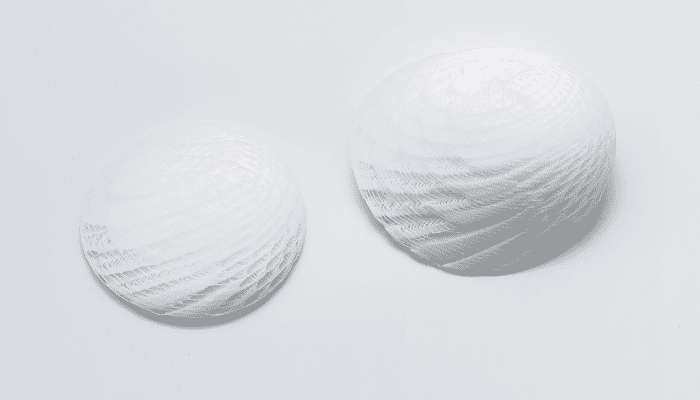

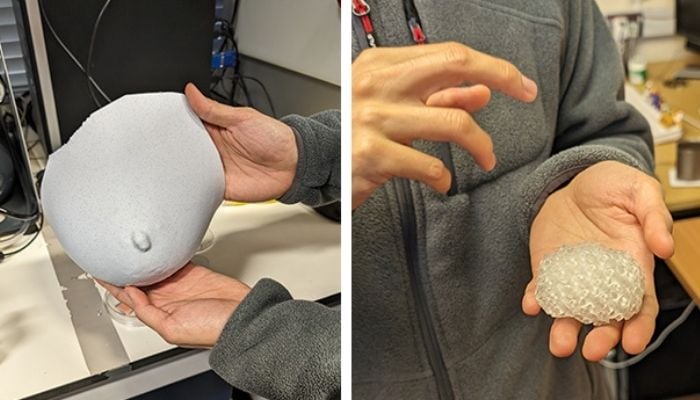

Recent research at the University of East Anglia (UEA) explores the use of 3D printing technology to improve breast reconstruction surgeries in cancer patients. The project involves creating customized molds using 3D scans of the patient’s breast prior to surgery, facilitating tissue measurement and optimizing shape and volume during reconstruction. This improves the quality and speed of the procedure. Another aspect of the research involves using MRI data to design customized implants printed in biodegradable polymers. These implants would be used in breast-conserving surgery, which involves removing the tumor while preserving as much of the breast tissue and shape as possible. This 3D implant would be placed in the patient and would degrade in the body after being injected with the patient’s own fat.

On the left, a 3D printed breast mold. Right, biodegradable implant with the exact shape of a tumor (Photo credits: University of East Anglia).

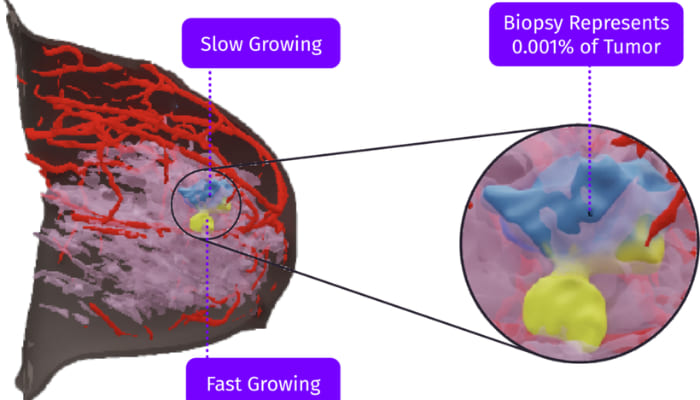

Ricoh and SimBioSys Unite AI and 3D Printing to Treat Breast Cancer

Ricoh USA, through Ricoh 3D for Healthcare, is a leading manufacturer of personalized medical devices. The company signed an agreement with SimBioSys, a tech company specializing in AI and computer modeling, to explore new technologies in breast cancer treatment. The collaboration focuses on evaluating the potential of artificial intelligence combined with advanced 3D printing to improve surgical experiences and personalize care for breast cancer patients. At the American Society of Breast Surgeons conference in April 2024, Ricoh and SimBioSys presented their first advances, unveiling innovative breast cancer models. Although details of the technologies used remain confidential, the collaboration promises to bring innovative solutions for the treatment and management of breast cancer.

Photo credits: SimBioSys

ZULE Offers 3D Printed Breast Prosthesis Alternatives

Last October saw the launch of ZULE, an innovative project from ESPOL (Escuela Superior Politécnica del Litoral) in Ecuador, which uses 3D printing to create customized external breast prostheses. This technological approach makes it possible to design prostheses that precisely fit the anatomy of each patient, ensuring comfort and a natural appearance. The team, led by Professor Gabriel Helguero, has developed a process that combines 3D scanning and modeling, allowing each prosthesis to not only adapt to the patient’s dimensions, but also to her scar. During the presentation of this initiative, the importance of early detection of this type of cancer was stressed. Likewise, the rector of ESPOL, Cecilia Paredes, highlighted how research, in this case driven by additive manufacturing technology, can transform lives and contribute significantly to the welfare of patients.

Photo credits: ESPOL / Escuela Superior Politécnica del Litoral

What do you think of the applications for 3D printing in the fight against breast cancer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.