MUSE: The First Star Stellarator With A 3D Printed Casing

Technological progress in energy production, free from reliance on fossil fuels, is undergoing exponential growth, facilitated by the emergence of new energy sources and cleaner processes. Today, we showcase a prime example of such innovation: plasma, a field that has been under study for years and is now experiencing a surge in advancements, largely thanks to additive manufacturing. In essence, plasma represents the fourth state of matter, wielding immense strength yet characterized by instability. To harness and explore its potential, specialized devices like star generators or stellarators, such as the one we highlight today, have been meticulously engineered and constructed.

Researchers at the Princeton Plasma Physics Laboratory (PPPL) have pooled their expertise to create a new type of stellarator generator with permanent magnets and a novel 3D printed housing. MUSE, as this new stellarator is called, is based on a less complex and less expensive production technique that will open up new avenues of study in nuclear fusion power plants. Researchers have turned to the development of MUSE as an enhanced solution for two key reasons. Firstly, they have opted for magnets with simpler geometries, and secondly, 3D printing has enabled the creation of a flawlessly circular casing, perfectly suited for containing the plasma.

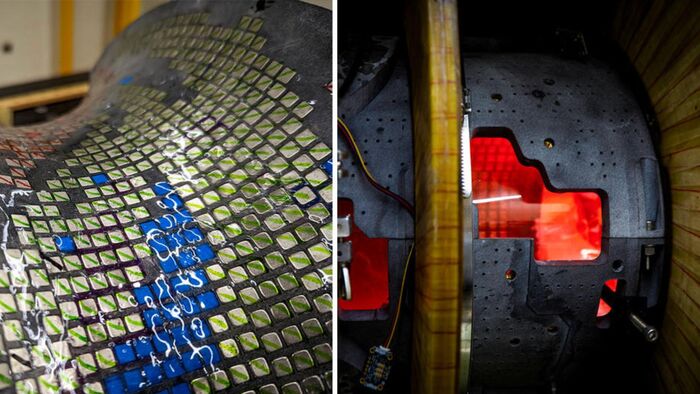

Permanent magnets from MUSE (left). The 3D printed housing (right).

The star generators that had been manufactured so far were very expensive because their structure was based on electromagnets with very complex geometries and which needed an additional flow of electricity to create their own magnetic field. However, recent PPPL research has shown that other magnets (permanent magnets), similar to “refrigerator magnets”, could also perform this function under optimal conditions. To support such magnets, a circular structure was needed that would be placed on the outside of the whole and would also be able to withstand the magnetic forces. This is where additive manufacturing came into play.

The Role of 3D Printing In The Manufacturing of MUSE

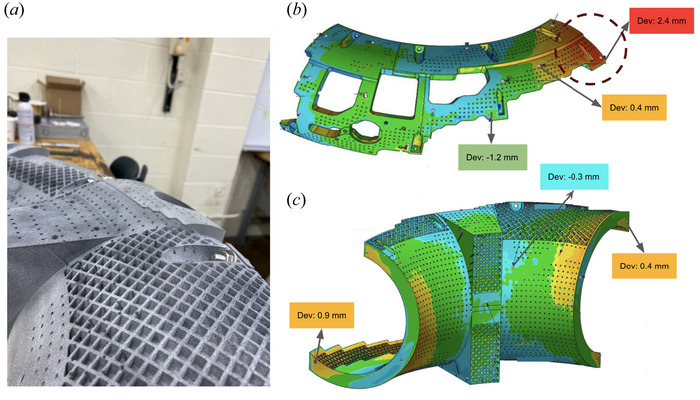

In their results, the researchers revealed that 3D printing met all the manufacturing requirements for the outer casing. Using additive manufacturing, a double-curvature bracket was created, with multiple cavities of different inclinations and radii where the magnets would go. This project of superior complexity was made possible by the design freedom of 3D printing, something that would have been more difficult to achieve with conventional manufacturing methods. During the development stage, several partial and full-scale prototypes were also manufactured, all using 3D printing.

Printed part and its rendering in OpenSCAD

MUSE was crafted with precision using OpenSCAD design software and brought into reality through the advanced capabilities of HP’s Multi Jet Fusion technology. The researchers carefully considered their options and settled on this particular technology for its remarkable ability to capture even the smallest details with finesse. While exploring alternatives like selective laser sintering, concerns arose about potential distortions due to heat during the cooling phase, leading the team to opt out of this approach.

In a PPPL press release, it has been stated that the creation of MUSE could lay the groundwork for the development of more affordable star generators. Certainly, 3D printing has conferred them to reduce the costs of both testing and the end result. Michael Zarnstorff, senior research physicist at PPPL explains, “MUSE is largely built with commercially available parts. By working with 3D printing companies and magnet suppliers, we can shop around and buy the precision we need instead of making it ourselves.” To learn more about this project, click here.

What do you think of this MUSE project? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: PPPL