TU Graz Achieves Breakthrough in 3D Printed Optically Active Nanostructures

Researchers Harald Plank, Verena Reisecker, and David Kuhness from Graz University of Technology have achieved a significant breakthrough in the production of 3D nanostructures, ensuring their precise shape and size to attain desired optical properties. The key to this success was the meticulous simulation of nanostructures (or nanoarchitectures), serving as a foundation for their fabrication. Additionally, the team effectively eliminated chemical impurities that commonly occur during the manufacturing process without compromising the integrity of the structures. These optically active nanostructures play a crucial role in applications such as solar cells, as well as chemical and biological sensors.

The objective behind nanoparticle production is to strategically apply them to surfaces, enabling the concentration, manipulation, or initiation of specific reactions of light. Although this practice has been in existence for two decades, the ongoing goal is to broaden the potential applications of this methodology.

A Decade of 3D Nanoarchitectures

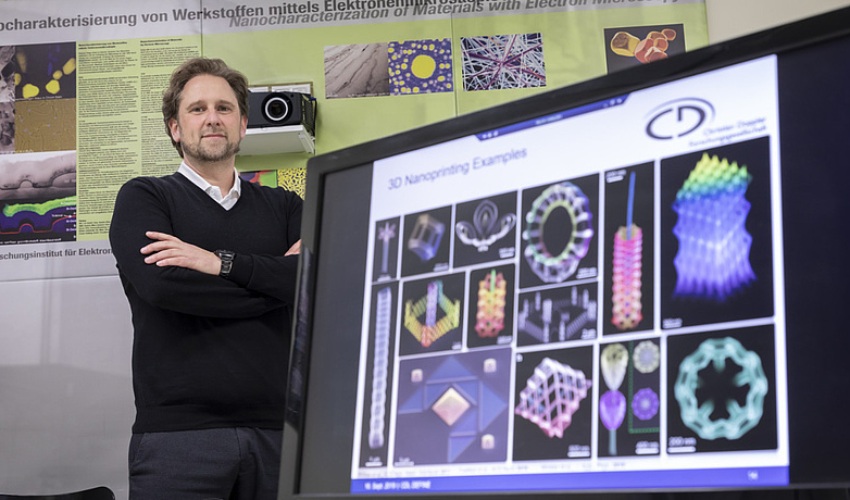

Over the past ten years, researchers at the Institute of Electron Microscopy and Nanoanalytics at Graz University of Technology and the Center for Electron Microscopy (ZFE) have been dedicated to advancing this vision. Their focus has centered on pioneering the development of intricate, self-supporting 3D architectures at the nanoscale, distinct from the conventional flat structures developed thus far.

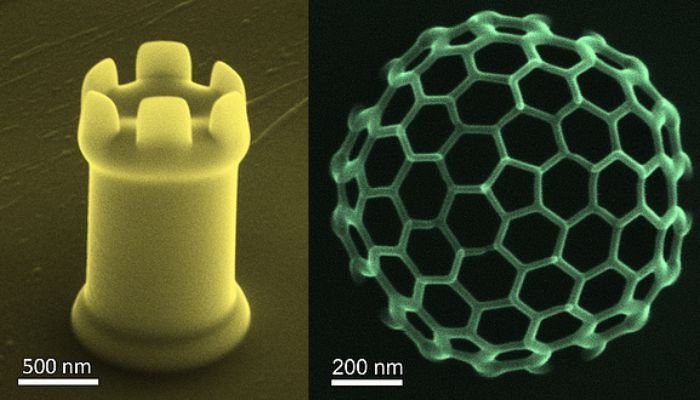

Structures manufactured using 3D nanoprinting technology; Left: Miniature chess tower, Right: Ball made of nanowires (Photo Credit: CDL DEFINE/TU Graz)

Harald Plank explains, “The hard work of the last few years has finally paid off. The biggest challenge in recent years was to transfer the 3D architectures into high-purity materials without destroying the morphology. This development leap enables new optical effects and application concepts thanks to the 3D aspect. Nanoprobes or optical tweezers with sizes in the nanometer range are now within reach”

How Exactly Are 3D Nanostructures Crafted?

At TU Graz, researchers employ the focused electron beam-induced deposition (EBID) process to create the 3D nanostructures. As part of the EBID process, the targeted surface is coated with specific gases in a vacuum. In order to convert portions of the gas molecules into a solid state and ensure their adherence to specific positions, these molecules are split with the help of an electron beam.

Harald Plank explains that the researchers are able to achieve production of complex nanostructures with lattice or sheet-like structural elements in a single step by precisely controlling the beam shift and exposure time. To achieve the desired three-dimensional nanostructures, the nanovolumes are meticulously stacked atop one another. Thanks to the advancements made by researchers at Graz University of Technology, optical tweezers or probes could be produced on a nanometric scale in the future. To learn more about this breakthrough achieved at TU Graz, click here.

What do you think about these recent developments in 3D nanostructure production? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: TU Graz