Ursa Major Propels U.S. Navy Missile Program With 3D Printing

Denver-based rocket innovator Ursa Major, a leading force in propulsion technology, has recently announced the company has secured a landmark contract with the US Navy’s Naval Energetics Systems and Technologies (NEST) Program. The collaboration aims to propel the Navy’s Standard Missile program into a new era of precision and reliability, strengthened by cutting-edge advancements in 3D printing technology. Additionally, through this partnership, the Navy will see the launch of new weaponry, specifically 3D-printed solid rocket motors (SRMs) built using Ursa Major’s Lynx approach to manufacturing.

Leveraging the recently unveiled Lynx, Ursa Major seeks a complete redesign of the Mk 104 dual-thrust rocket motor, the workhorse powering the Navy’s Standard Missile family. This component, critical for a diverse range of missiles, drives the SM-2, essential for surface-to-air defense; the SM-3, critical for ballistic missile defense; and the SM-6, a versatile anti-air, land, and sea missile. Notably, the SM-6 is the only multi-role missile capable of intercepting hypersonic threats – a growing concern for national security.

Launch of an SM-6, powered by the Mk. 104 dual-thrust rocket motor component. (Photo Credits: U.S. Navy)

Ursa Major’s Lynx approach tackles longstanding hurdles in SRM production by integrating 3D printing with a versatile tooling system. This method, encompassing a variety of additive manufacturing technology and techniques, promises to streamline the production process, slashing lead times and boosting overall reliability – crucial factors for rapid response capabilities. The use of 3D printing will prove especially beneficial, as manufacturing current versions of the Mk 104 dual-thrust rocket motor presents a significant challenge due to its complex and time-consuming processes. This bottleneck coincides with a critical period for the US Navy, as domestic demand for SRMs is surging, driven by the need to replenish stockpiles and support Ukraine’s ongoing conflict.

Joe Laurienti, the Founder and CEO of Ursa Major, expressed profound enthusiasm for the partnership, stating, “We are proud of the Navy’s support and recognition of Ursa Major as a trusted partner to develop the next generation of Mk 104 solid rocket motors. Our new approach to manufacturing SRMs allows Ursa Major to quickly develop high-performing motors at scale, driving volume and cost efficiencies to address this critical national need.”

Captain Thomas Seigenthaler, Director of PEO IWS 3.0, echoed the sentiment, adding, “PEO IWS is excited to work with Ursa Major on this effort to bolster a critical component of the Nation’s industrial base. The production of solid rocket motors is a top priority, and we are impressed with Ursa Major’s innovative approach to address manufacturing challenges.”

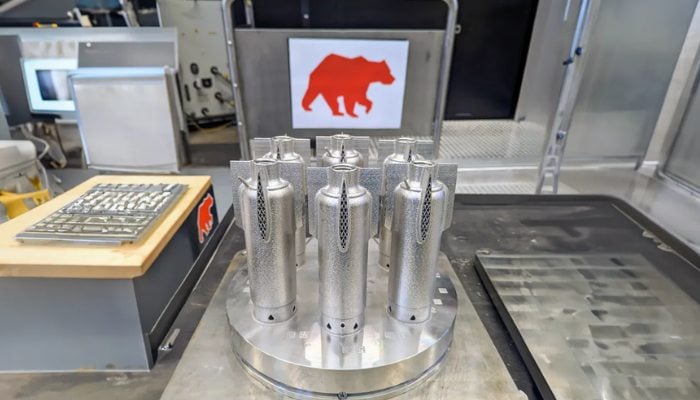

Small prototype motors. (Photo Credits: Ursa Major)

This initiative signifies the Navy’s continued efforts to modernize its fleet and arsenal to meet the demands of contemporary warfare. Furthermore, it follows the growing trend of military adoption of 3D printing in the push for state-of-the-art technology. To learn more about Ursa Major’s Lynx approach, click here.

What do you think of the U.S. Navy’s partnership with Ursa Major? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: U.S. Navy