The Complete Guide To Glass 3D Printing

Glass or crystal is a hard, brittle, transparent and amorphous inorganic material found in nature, although it can also be man-made. In additive manufacturing, it is an unusual material, but one that can be processed to create original glass parts, layer by layer. Thanks to emerging research into this manufacturing method, 3D glass printing is gaining in popularity, prompting more and more companies to develop their own solutions.

What’s more? The technology is attracting the attention of scientists and artists alike, as it opens up new avenues for glass manufacturing. To better understand this material, we have developed a comprehensive guide on glass 3D printing, including its characteristics, benefits, limitations and most notable applications.

Glass 3D Printing Characteristics

Before diving into the manufacturing process itself, let’s take a look at the material. Glass generally occurs naturally in the form of obsidian, generated when volcanic lava with a high silica content cools rapidly, without forming crystals. The type of glass that most are familiar with is highly versatile, coming in many color and with different properties.

Indeed, although we talk about glass in general all the time, there are in fact different variants. Depending on whether a user is working with soda-lime glass, art glass, crystalline glass or recycled bottles, the manufacturing temperature may vary slightly to achieve the desired results.

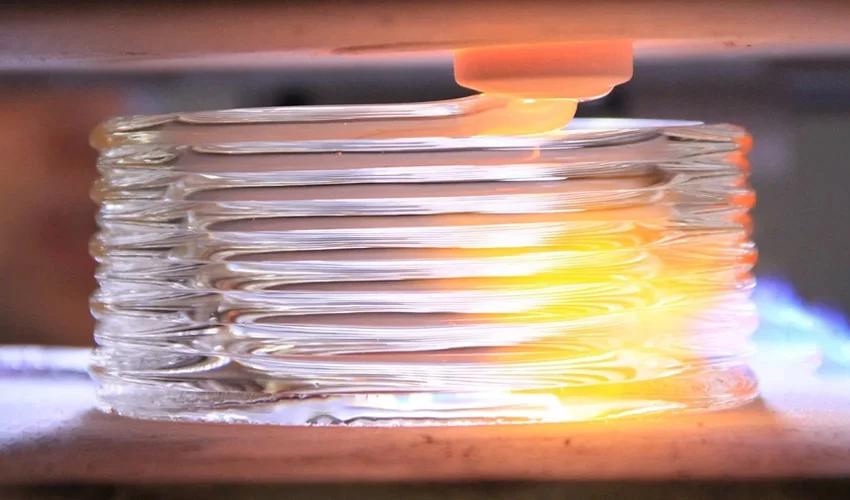

Parts created by glass 3D printing (photo credits: Chikara Inamura)

In terms of 3D printing with glass, as with all additive manufacturing process, first it is necessary to put the design through a slicer to generate the G-Code. Then, the glass rods must be inserted into the machine through a hole that leads to the heating element. There they are melted to the optimum manufacturing state, before passing to the nozzle of the printer.

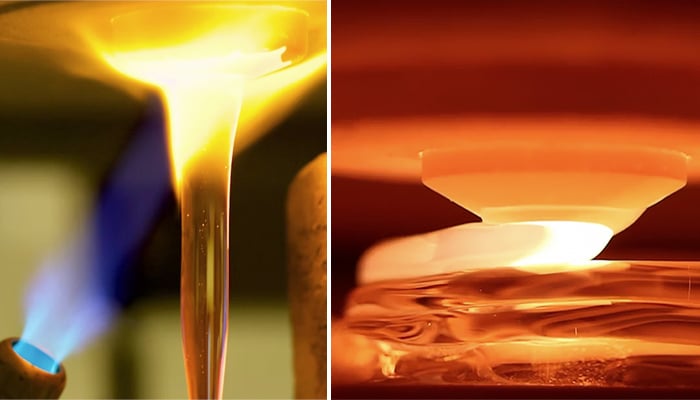

It should be noted that, although the layer-by-layer deposition process is very similar to the well-known FDM, very high melting temperatures are required when working with glass. Although it will depend on the type of glass, the temperature must be around 1300ºC in order to be extruded and applied on the manufacturing tray.

During manufacturing, the part is held in a closed chamber at around 400°C until the end of the process. The model is then slowly cooled down to room temperature. Once cooled, the parts may require some post-processing, although in general they are almost ready for use. Glass 3D printing is still in its infancy, and continues to grow steadily. For this reason, specific printer configurations and recommendations may vary as it develops.

Benefits and Applications

One of the most obvious advantages of additive glass manufacturing is its relationship with recycling. Glass is a material that can be recycled again and again without affecting its properties. In terms of design, additively manufactured glass enables the creation of precise lines, unique curves and internal geometries. Moreover, the passage of light through 3D-printed glass creates an aurora effect, dispersing and reflecting light through the lines and surface layers.

Glass 3D printing requires high manufacturing temperatures

In terms of applications, 3D-printed glass is mainly used for the creation of purely aesthetic objects. Being a fragile material, it is not generally used in industries where high mechanical properties are required, such as strength or durability. Sectors that can most benefit from the advantages of glass 3D printing include art, architecture, optics and jewelry.

Scientific research is another application where additive glass manufacturing plays an important role. It is an indispensable experimental asset in many STEM fields due to its intrinsic properties and the need for customization offered by 3D printing.

Main Manufacturers on the Market

One company known for its glass 3D printing solution is Maple Glass Printing, with the Maple 3. With a maximum manufacturing volume of 170 x 200 x 300 mm, this machine is capable of creating glass parts at high speed. In addition, the company has developed a device called Vitri-Glass, which transforms recycled and ground glass waste into bars with diameters between 3.5 and 6 mm for use with its 3D printer.

Another name to consider in this market is Nobula3D. This Swedish company is working with this technology while waiting to formalize a patent that will enable it to market its desktop 3D printer for glass. Finally, Neri Oxman’s research group at the Massachusetts Institute of Technology (MIT) was one of the first to study this manufacturing method.

To this day, he sells 3D-printed decorative pieces from his Evenline studio. Although they haven’t yet commercialized their solution, they are at least making their 3D works available to the public. And while there aren’t currently many more players developing this process, it’s expected that the massive research push will bring more technologies of this type to market.

What do you think of glass 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: MIT