Verne Unveils More Affordable PEKK SLS 3D Printer

It is no secret that there are very few SLS 3D printers that are compatible with high-performance polymers. In particular, SLS-PEKK 3D printing has found it difficult to establish itself on the market, as the acquisition costs are higher than for classic SLS printing and the powder required is also very expensive. However, the new SLS printing system STROM, which was designed by Verne Additive Manufacturing Labs, is now set to change this.

Back in 2014, the team founded the startup Norge, which developed the first affordable SLS 3D printer. This offers functions that were previously only available in industrial systems and thus achieved a significant breakthrough. The company also became known for its laser sintering printing systems, which are used by industrial companies in Europe and Asia. Now, Verne AM Labs is exciting a new project: the STROM project, which aims to make high-performance SLS printing more accessible and user-friendly, in particular through the development of a new printer. The team is currently working on software and machine design and prototype testing is planned for fall 2024, with the aim of starting series production in June 2025.

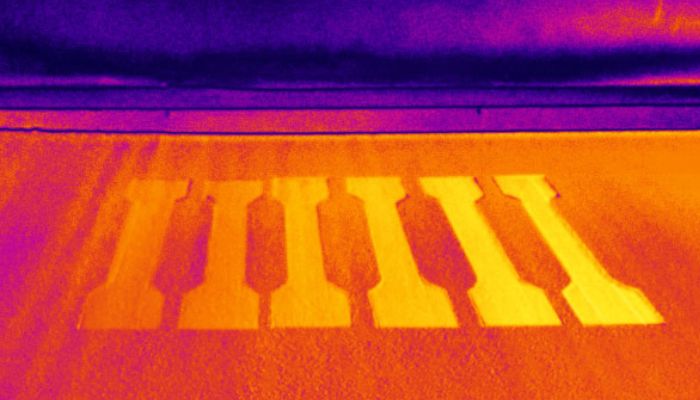

The temperature control system, which has an IR camera

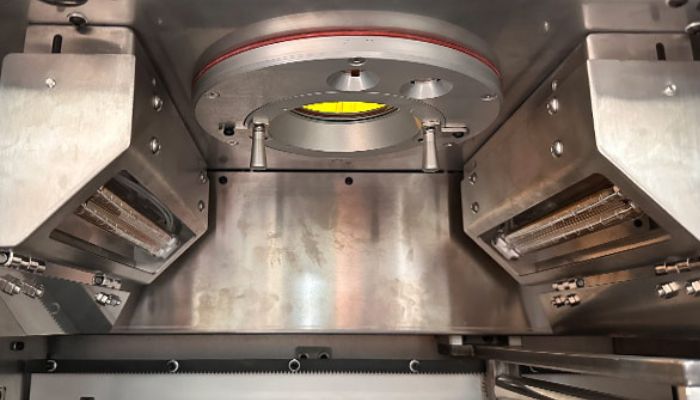

The new PEKK SLS solution, which has a build volume of 220 x 250 x 400 mm (about 22 liters), enables high-temperature SLS printing, making it suitable for high-performance thermoplastic materials. It is also said to be compatible with the requirements of research centers, laboratories and OEMs and can be used in these areas.

Particularly impressive is the printer’s ability to reach temperatures of up to 380°C in the build chamber, supported by an intelligent temperature control system with integrated camera. In addition, the printer offers layer-by-layer image analysis quality control, which ensures that the tools are monitored. The machine also uses artificial intelligence in the areas of scanning strategies and laser power management to efficiently improve mechanical properties and printing speed. The PEKK laser sintering 3D printer can process high-performance materials as well as standard SLS powders, including PA12, PA11, PP, TPU and PA6.

The printer is to expected to become part of an overall system. This includes innovative systems that contribute to the intelligent workflow, such as IntegAM Fibroblast Air, a powder removal system, and IntegAM SurfPro, which can be used for surface finishing. The SM-1 automatic powder management system enables automatic sieving, mixing and transfer of the powder.

The chamber of the SLS PEKK printer

The project offers numerous advantages, above all through an affordable purchase price and a faster market launch of the printed components. The compact print volume of the PEKK SLS 3D printer should also enable optimal and efficient use of the printing platform to accelerate innovation. You can find out more about the PEKK printer and the project HERE.

What do you think of the STROM project and the SLS-PEKK 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Verne Additive Manufacturing Labs