Researchers Use 3D Printing to Create Helical Tubes Inspired by Shark Intestines

Additive manufacturing is increasingly being used for research discoveries by laboratories and university teams. This is because the technology makes it possible to investigate elements and details that other methods cannot reproduce. Recall, for example, the recent example of an Egyptian mummy, which, thanks to 3D technologies, was able to be studied without disturbing the artifacts. This is possible mainly because researchers can 3D scan the part that needs to be studied before obtaining a digital twin of the part and then reproducing it through 3D printing. And it continues to be done. For example, team of researchers at the University of Washington, led by physicist Ido Levin, has turned to 3D technologies to investigate the workings of the shark’s intestine in order to mimic it in a variety of applications, from developing helical tubes to developing so-called “soft robots,” or soft robots inspired by nature.

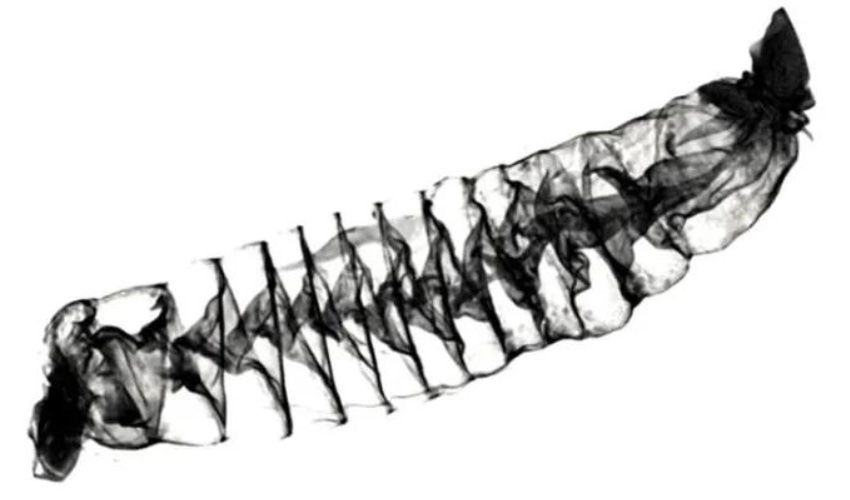

Contrary to popular belief, we don’t know much about what sharks eat or how their intestines work. The first images that led to a breakthrough on the topic were those released in 2021 by the team composed of researchers from California State University Dominguez Hills, University of Washington and University of California. The researchers used a 3-D scanner to scan dogfish shark intestines from specimens preserved at the Natural History Museum in Los Angeles and create 3-D images that could be studied.

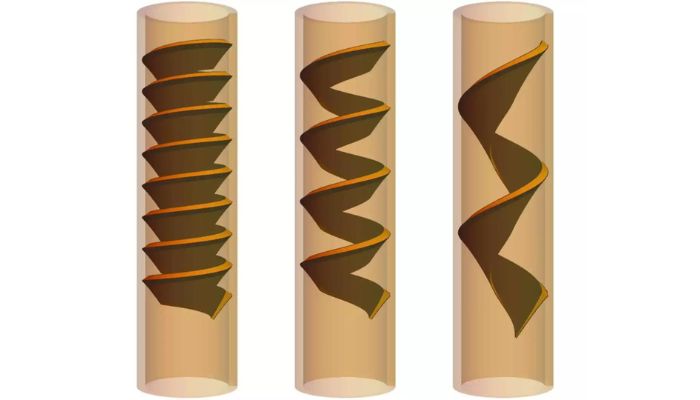

The results were extraordinary and led to the understanding that these spiral-shaped organs slow the movement of food and direct it downward through the intestines, relying on gravity in addition to peristalsis, the rhythmic contraction of the smooth muscles of the intestines. The intestines would function in the same way as the valve patented by Nikola Tesla in 1920. Furthermore, a recent study suggests that these structures also have asymmetrical flows, promoting flow along the digestive pathway (from the front to the back). The team at the University of Washington wanted to take advantage of these characteristics to create better helical tubes.

3D Printing to Create These Shark Intestine-Inspired Devices

The study yielded results in February 2023, after researchers 3D printed replicas of the shark intestine to study its underlying physics. The University of Washington team, led by physicist Ido Levin, then 3D printed simplified biomimetic models of helical shark intestines. By measuring the flow of various fluids through these structures in both directions, it was possible to extract their hydrodynamic properties. By printing the structures with softer materials, the researchers investigated the interaction between tube deformation and flow rate.

Photo Credits: Ido Levin/ University of Washington

These results are important because they will be able to be used to design structures that require control of fluid flow and pumping. Such an ability to control flow direction has significant potential in engineering applications ranging from industrial piping, microfluidic devices, and soft robotics to medical implants. It could therefore be useful in many industries, including the food, medical, pharmaceutical, and energy industries. You can learn more about the study in the publication HERE.

What do you think of this? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo: CT scan image of the spiral intestine of the Pacific spiny dogfish shark (Squalus suckleyi). The beginning of the intestine is on the left and the end is on the right (photo credits: Samantha Leigh/California State University Dominguez Hills)