Mummy Research Used 3D Printing to Reveal Archaeological Secrets

In ancient Egypt, preparation of the dead was an important occasion, one which would allow the person to pass into the afterlife. Embalmers performed mummification of deceased people, protecting the body from the decay of the human or often animal body. Despite the discovery of an increasing number of mummies as time continues, investigating these artefacts is challenging since with a wrong movement the mummy could be destroyed. That’s why researchers used CT scanning to study a mummy recovered in Upper Egypt in 1916, but also used 3D printing to reproduce an amulet found there.

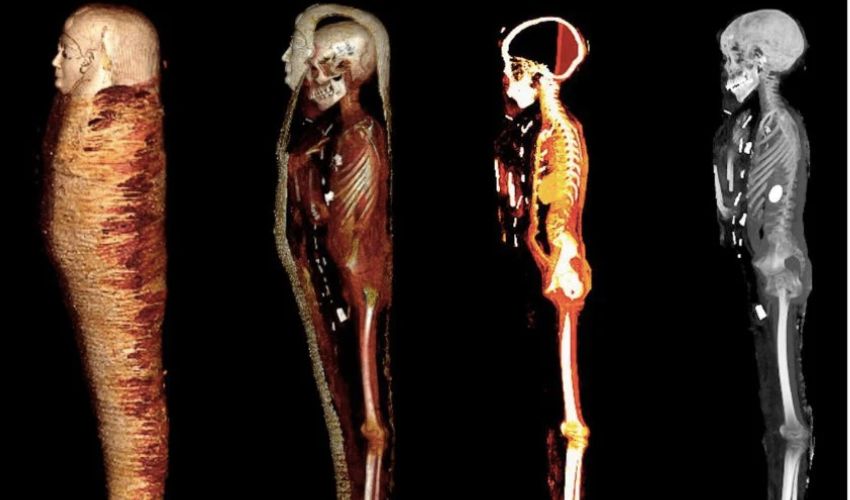

Additive manufacturing has already been able to demonstrate its suitability for use in archaeology. But in this case, the researchers in Cairo explain that it was only after performing the CT scan that they came across what was actually special. The result of the scan revealed a total of 49 amulets placed inside the mummy and between the wrappings, which were given to the mummy in 21 different forms to take with him on his final journey. The “golden boy”, nicknamed for the 30 golden amulets it was buried with, provides further provide information about living conditions at that time. This was aided with the means of 3D scanning and printing.

Left: the scan of the outermost bandages; right: the scan shows the crossed arms and the amulets.

The Procedure for Researching the “Golden Boy” Using 3D Printing

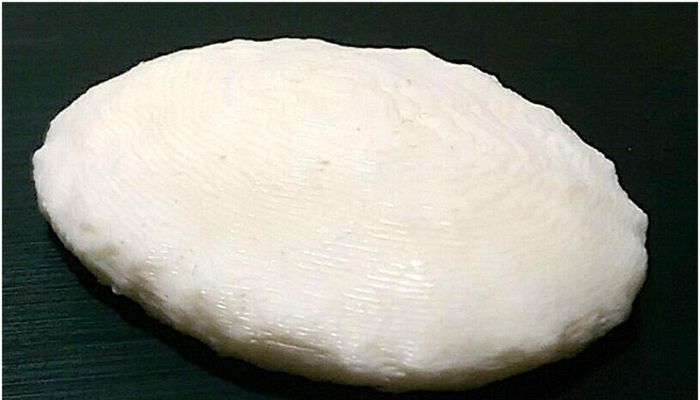

In their paper titled “Scanning and three-dimensional-printing using computed tomography of the “Golden Boy” mummy,” which appeared in the journal ‘Frontiers in Medicine,’ the researchers stated that after successfully scanning the selected object – in this case, the largest amulet located in the mummy – they transferred it into a printable format. Since this heart scarab was located in the chest cavity of the mummy, which was probably 14 to 15 years old at the time of death, the researchers indicated that the ancient Egyptians held their children in extremely high regard. One drawback noted by the research team is that due to the overlap of the 3D file of the amulet on the 2D X-ray film, there was a loss of data.

The STL file was then manipulated within the software using the tools so that the researchers obtained the surface shell of the amulet. According to the research team, a commercially available 3D printer was used to finally 3D print the amulet. Specifically, it was the Dremel 3D40 Ideal Builder, which uses the Fused Deposition Modeling (FDM) process. The material used in this case was a white ABS plastic material, which was subsequently 3D printed with a layer thickness of 0.1 mm based on the CT data. The result after 3D printing was an impressively detailed disc-shaped amulet. Even the engraved characters on the amulet were clearly visible and it was even possible for the researchers to interpret them. The assumption is that these were ritual inscriptions intended to protect the heart.

The amulet was 3D printed using ABS

The researchers from the Department of Radiology at Cairo University and the Egyptian Museum in Cairo conclude their research by adding, “We anticipated that this study would provide information about the mummy that could help with conservation and promote the display of the mummy in the museum’s exhibition space.” If you would like to learn more about the use of 3D printing of the “golden boy” mummy, you can find the research paper HERE.

What do you think of the use of 3D technologies for archaeology of mummies? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: Sahar N. Saleem et al./ “Scanning and three-dimensional-printing using computed tomography of the “Golden Boy” mummy”