SPREAD on Its Mission to Streamline Engineering

The world of engineering and manufacturing is rapidly evolving, driven by advancements in technologies like 3D printing. In this interview, we sit down with Robert Göbel, co-founder of SPREAD GmbH, a pioneering force in simplifying access to product information through their Engineering Intelligence Network. As industries strive to innovate and streamline processes, the synergy between engineering insights and 3D printing technologies becomes increasingly vital. Join us as we explore how SPREAD’s innovative approach not only bridges the gap between these realms but also revolutionizes how companies like Mercedes, Porsche, and VW are shaping their futures through development, quality enhancement, efficiency gains, and a commitment to sustainability.

3DN: Could you introduce yourself and tell us about your company?

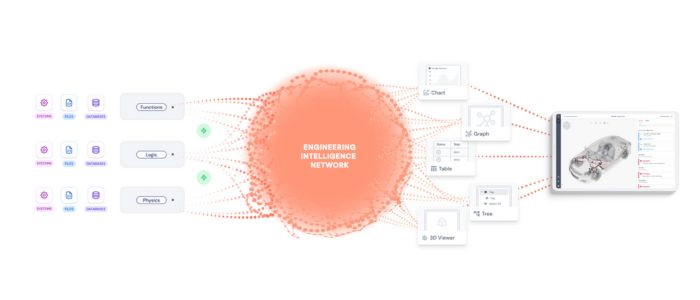

Hey everyone, I’m Robert Göbel, co-founder of SPREAD GmbH. SPREAD is committed to simplifying the access and application of product information for everyone. Through our Engineering Intelligence Network, we transform your product data into user-friendly, intuitive, and actionable insights. Our platform seamlessly integrates various forms of product information, facilitating engineering teams in comprehending intricate systems such as automobiles, aircraft, and machinery. Catering to a range of applications from Research and Development to Aftersales, SPREAD’s Engineering Intelligence Network has been instrumental in propelling the advancement of esteemed clients like Mercedes, Porsche, and VW. By expediting development cycles, enhancing quality, minimizing inefficiencies, and fostering sustainability, our platform is reshaping the landscape for these industry leaders.

Meet co-founder of SPREAD GmbH, Robert Göbel

3DN: How does your software function?

Imagine a complex product like a car. You need thousands of highly specialized engineers and millions of lines of code to bring it from development to production. It is almost impossible to understand the interplay and the connections of all the mechanics, the electronics, and the software components. Engineers spend 70% of their time manually searching for product information. This is because their tool landscape is fragmented, causing essential information to be isolated or difficult to access. They need this information to get a complete understanding of how their product works. If you think about the huge effort that goes into manually building this contextual understanding, it is remarkable that engineers can make such innovative and complex products work. SPREAD’s Engineering Intelligence Network combines all separate product information sources into a knowledge graph of the product. This graph acts like a middle layer that interconnects resources or data streams with Opensource and open APIs data that are relevant for different use cases.

3DN: How can Engineering Intelligence Networks like SPREAD heighten efficiency in the 3D printing industry?

Our software helps engineers working on complex products quickly and intuitively get the information they need. Having all product information connected and accessible means engineers can identify opportunities to make the product more efficient. In the case of the 3D printing industry, our capability helps engineers access a system across parts, components, and domains, which is extremely valuable for one of the key questions in industrial 3D printing: which individual part combinations to replace with 3D printed components. Based on the information of all individual parts in the network, we can suggest the part combinations that carry the most potential to be printed as one unified component instead of individual parts. The more information we have in the network, the more valuable improvement potentials we can identify.

3DN: How does SPREAD reduce companies’ environmental footprint?

Our technology creates a knowledge graph for each product incorporating its carbon footprint and making it accessible via a web application. It gives customers traceability and transparency over the lifecycle, and they can apply different rule sets, such as sustainability regulations, to verify if all the involved parts from various sources meet the requirements. SPREAD analyzes designs and identifies material redundancies and optimization potential based on the requirements. This helps reduce excess weight without compromising safety or functionality. For example, it is possible to analyze existing wiring harness designs and help engineers use these insights to eliminate excess materials in their wiring design process and therefore reduce their carbon footprint. With this approach we allowed one automaker to save 1 kg of material per vehicle. Every kilo saved makes this car manufacturer reduce their scope 1, 2, and 3 emissions. The automotive industry had a global production volume of 80 million vehicles in 2021. Scaling this 1 kg savings to the global output, it would prevent 2,730,000 tons of CO2 from being released into the atmosphere.

3DN: Who are your partners today and what are your future developments (in terms of customers, and research)?

We collaborate with all the German Automotive OEMs and are also building on our first successes in the heavy machinery, and aerospace & defense industries. Going forward, we want to scale our successes to new markets. We want to develop our platform’s capabilities, increase our user base, and grow our team.

3DN: Any last words for our readers?

We’re hiring! Check out our website HERE and reach out if you want to learn more.

What do you think of SPREAD’s Initiative to streamline engineering? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: SPREAD GmbH

The equipment and machines used in mechanical engineering are often too complex to be clearly represented in sketches or mockups, but 3D models are much more practical, and are considered one of the best digital solutions in the industry. I fully support Robert Goebel’s words about the proactivity of using software.