Ginger Additive Talks Making Pellet 3D Printing More Accessible

The use of pellets as a material for extrusion 3D printing is proving to be an increasingly viable technology. Already it is offered by a number of players in the market, particularly for large-format 3D printing. In fact, the benefits of using pellets for 3D printing are many: from the use of a wide variety of plastics, to increased sustainability due to the potential to use recycled material and even the ability to power large robotic arms, making works possible that were until recently unfeasible with additive manufacturing. We discussed this and more with Ginger Additive, a young Italian startup that has decided to focus on this very technology to make it increasingly accessible.

3DN: Could you introduce yourself and tell us about your connection with 3D printing?

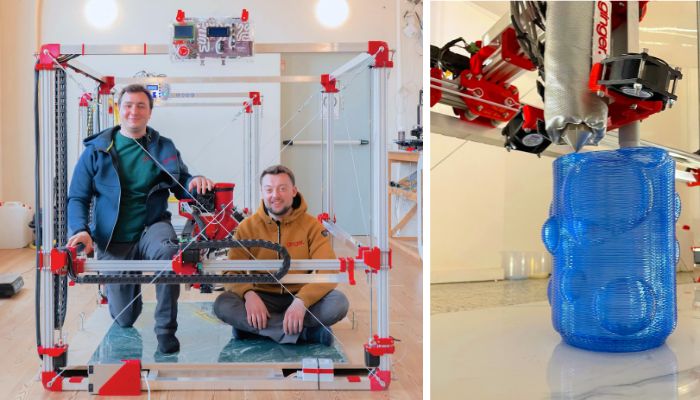

Hi everyone, we are Umberto Bisotti and Davide Malnati, founders of Ginger Additive. We are two under-30 engineers who studied together at Politecnico di Milano. Almost 3 years ago, we made our first prototype for pellet 3D printing and realized the huge potential of this technology. So we founded Ginger Additive and currently manufacture and sell Ginger.one, the first low-cost printer using FDM technology with pellets. In addition, our production department works closely with designers and design studios for the manufacturing of specific parts.

Umberto Bisotti and Davide Malnati with their solution, Ginger.one

3DN: How did Ginger Additive come about and what is its mission?

Ginger Additive is a Milan-based startup working on large-format pellet 3D printing. 3D printing is destined to be, in its countless variations, a sure option in the manufacturing world. However, pellet printing has, to date, still been lacking. Though it is a technology that is already well-developed, it is still searching for its place in different sectors. The machinery on the market as of now reflects this situation. So today Ginger’s mission is very simple: accessibility. We want to develop technology that can be used in everyday life and also open the doors of this world to SMEs and independent professionals.

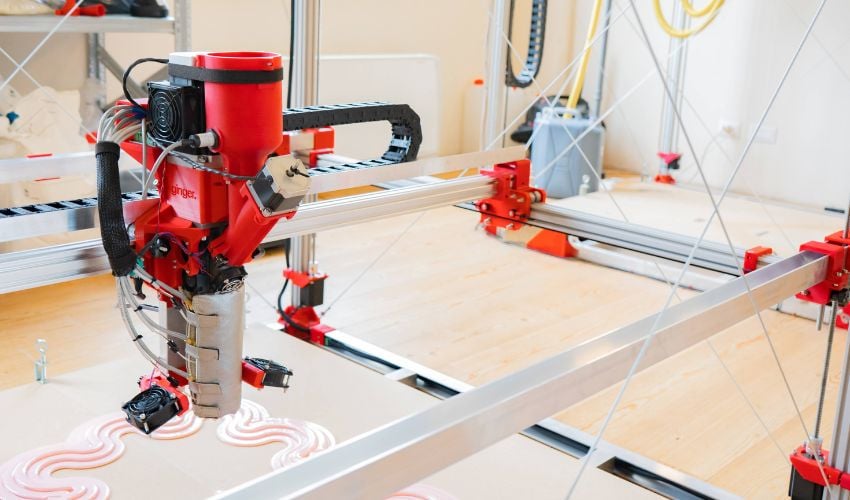

Ginger Additive’s solution, Ginger.one, is a pellet 3D printer designed to be a solution for low to medium complexity projects. It works with granule extrusion technology, up to 2 kg/h, with industrial pellets. It has a print volume of 1 m x 1 m x 1 m, low energy consumption and most importantly a low cost compared to the market. Ginger.one is a Cartesian with an optimized footprint that could therefore fit easily in a living room or small studio. A large part of the components of our printer are themselves 3D printed and all files are supplied with the machine. This allows for self-maintenance and also the possibility of modifications.

3DN: What are the benefits of using pellets, as opposed to filament, as a material for FDM 3D printing?

Pellet extrusion makes it possible to use the industrial plastic format, and thus cut down the cost and consumption of the filament production step. It also makes possible the use of uncommon, loaded materials, materials with which it would not be possible to make a filament, and especially the direct use of shredded and recycled plastic. Filament also does not allow the use of nozzles larger than a couple of millimeters. Our machines basically use nozzles up to 8 mm, for line thicknesses of up to 2 cm. This allows high extrusion flows to cut down the variable cost of printing time.

Pellets are the key to large format additive manufacturing. Printing with filament above certain sizes becomes a dastardly choice for both cost and printing time. The only obstacle to the widespread use of this technology at this time is the fixed costs of equipment, which is why Ginger Additive exists.

A part made with pellet 3D printing on the Ginger.one from Ginger Additive

3DN: What markets and applications is Ginger Additive targeting?

The world of design, particularly with regard to furniture, is definitely the area where this technology can make the most difference. And it is already something that has been taking root for a few years. We target this sector both as a machine manufacturer and as a manufacturing force. In fact, almost all of our machinery sold to date has gone to design and architecture firms. Obviously, the flexibility of 3D printing and its materials leaves room for areas that can go from pure aesthetics to total functionality.

Working shoulder to shoulder with artists and designers, Ginger Additive has been lucky enough to see many incredible projects come to life. We can with pleasure mention those that we were involved in, for example, at the last Milan Design Week. Among them: the printing of beautiful and striking Buoy lamps, which were up to 5 meters high, by Parisian designer Lucas Zito, the collaboration with Lyla Design studio that develops online software for intuitive modeling of furniture objects, or the printing of a special natural lacquer deposited by an insect, in collaboration with designer Ori Orisun.

Photo Credits: Ginger Additive/Lucas Zito

3DN: Any last words for our readers?

We would like to thank 3Dnatives and all your readers. We hope that in the very near future seeing a 3D printed chair or lamp, in a house or bar, will be an absolutely common thing! You can find out more about Ginger Additive HERE.

What do you think of Ginger Additive? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Ginger Additive