#3DExpress: Aurora Labs Unveils Lighter, Higher-Performance, 3D-Printed Turbine

It has been a busy week for 3D printing! And we are happy to tell you all about it in this;s 3DExpress which highlights some of the tidbits you may have missed from the week. First, learn more about the latest project from Australian company Aurora Labs: they’ve come up with a lighter, more efficient 3D-printed metal turbine. Then, check out the new metal 3D printer from Nikon. Finishing it off, we checked out the new expansion from Sintavia in Florida, Anycubic’s teasing of new products and Materialise’s new materials. Happy reading and have a great weekend!

Aurora Labs and its 3D-printed turbine

Aurora Labs, an innovative industrial technology and development company based in Canning Vale, Australia, has announced the successful manufacture of a metal 3D-printed engine, with a particular focus on a new, lighter, higher-performance turbine. The latter, due for launch next month and available for lightweight propulsion systems in a wide variety of markets, is a 200N-class gas turbine engine. According to the company, it has been successfully designed, printed and tested. What’s particularly interesting about this project is the design phase: the aim was to produce a lighter turbine. The teams therefore sought to reduce the number of parts making up the turbine, and eliminate assembly steps where possible. For one part of the engine, for example, they succeeded in assembling 18 parts into a single unit, reducing weight by 20%.

Photo Credits: Aurora Labs

A New Metal 3D Printer From Nikon

Nikon has announced the launch of a new metalworking machine, based on DED. Called Lasermeister LM300A, the solution has been designed for industrial applications. It goes hand in hand with a new 3D scanner, the Lasermeister SB100. The aim is simple: to enable parts such as turbine blades or molds to be repaired quickly and efficiently. In concrete terms, the damaged component is placed inside the 3D scanning solution. This analyzes the part, measures it and generates the data for the 3D printer’s repair path. This data is sent to the DED machine for printing. Once the Lasermeister LM300A has finished, the part is returned to the 3D scanner for inspection and validation of the repair. A solution that should offer greater automation and minimize the risk of errors. In terms of materials, the DED 3D printer is compatible with SUS316L stainless steel, nickel-based alloys (Ni625, Ni718), titanium (Ti64/Ti-6Al-4V), and high-speed steel (SKH51/M2/HS6-5-2).

On the left, the 3D scanner; on the right, the DED 3D printer (photo credits: Nikon)

Sintavia Announces $25M Hollywood Expansion

Sintavia LLC, which considers itself to be the world’s first all-digital aerospace component manufacturer, announced this week its large expansion in facilities and equipment since 2019. The $25 million expansion, to be completed in the fourth quarter of 2024 in Hollywood, Florida, is expected to include additional advanced manufacturing space (notably with a long-term lease on an additional 25000 ft2 of manufacturing space adjacent to its existing headquarters for printing, post-processing and materials testing), large format printers, large format post-processing equipment and component testing. The investment was deemed necessary to meet the demand from programs it supports across the U.S. Department of Defense. Furthermore, a major focus of the expansion will be the continued design and development of high-performance thermodynamic components such as aerospace heat exchangers, according to a press release from the company.

The expansion includes the purchase of a second SLM NXG XII 600 (photo credits: Sintavia)

Anycubic Teases New Launch

There’s no need to introduce Anycubic, a Chinese manufacturer of affordable, easy-to-use 3D printers. This week, it presented its roadmap, announcing the long-awaited arrival of the Kobra 3 Combo FDM machine. This is a fast (600 mm/s) 3D printer that can print up to 8 colors simultaneously. The solution is even said to be able to distinguish between filaments and colors. In addition to this launch, Anycubic is also enhancing its Photon resin machine range with the Photon Mono M7 Pro and M7. The Pro version is said to feature a smart assistant capable of understanding all stages of the printing process. OuYang Lu, founder of Anycubic, concludes: “Our goal is to elevate our users’ entire 3D printing journey with the latest technological trends, optimal functionalities, and premium quality. In 2024, we plan to introduce a comprehensive lineup of products designed to inspire individuals in every household to unleash their creativity.”

Anycubic to unveil its solutions shortly (photo credits: Anycubic)

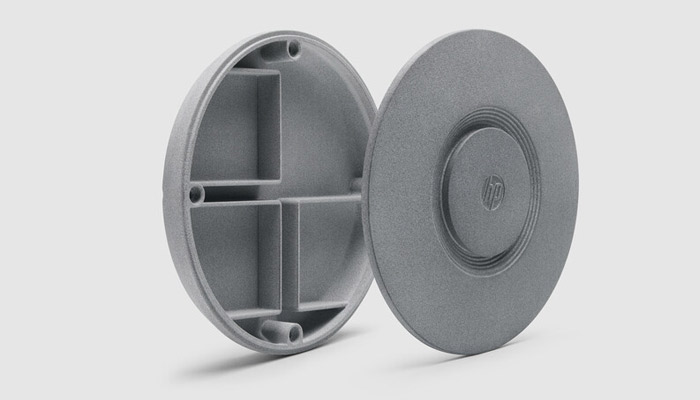

Materialise Adds Materials to Its Portfolio

Belgian 3D printing service Materialise announced this week the addition of 3 new materials to meet its customers’ needs. These are PA12S and PA11 powders for Multi Jet Fusion technology, and a carbon fiber-reinforced polyamide filament for FDM. A total of 38 materials are now on offer, enough to satisfy a wide range of professionals. Pieter Vos, Marketing and Product Manager at Materialise, comments: “Our decision to incorporate PA 11, PA 12S, and PA-CF materials into our portfolio reflects our commitment to meeting the evolving needs of our customers and empowering them to explore new possibilities and unlock the full potential of industrial 3D printing. We constantly evaluate emerging materials and technologies. The new HP PA 12S is a strong addition, and we are proud to be an early adopter.”

Parts 3D printed with PA12S (photo credits: Materialise)

What do you think of this new 3D printed turbine from Aurora Labs? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.