WASP Unveils New Parametric Design Software App

WASP holds a significant position within the construction 3D printing sector. The company from Italy has introduced the WASP App, a parametric design software aimed at enhancing the user experience in crafting with clay. Clay has emerged as a primary material for this Italian manufacturer, serving as a viable alternative to concrete for construction that is both more sustainable and less environmentally taxing. By 2021, concrete is projected to contribute to 7% of CO2 emissions, according to the World Cement Association.

WASP’s proficiency in clay-based construction has already been evident through its 3D-printed architectural projects. The TECLA house stands out as a compelling instance, showcasing the use of locally-sourced materials and notably minimizing waste. This prototype acts as a catalyst for the development of ecologically conscious urban areas composed of similarly designed homes. Additionally, WASP has partnered with Dior to establish a pop-up store in Dubai. By employing 3D printing in these structures, the luxury brand’s handbags are artistically portrayed through diverse patterns featured on the walls.

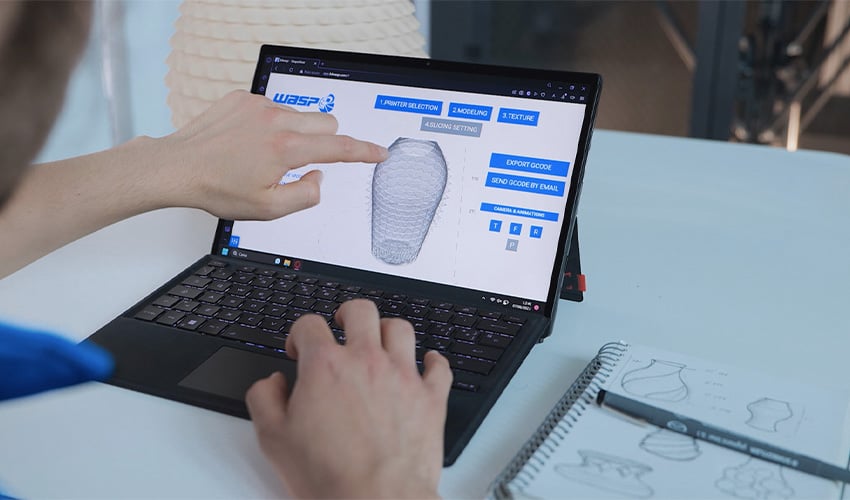

The WASP App is suitable for designing 3D printed clay parts

The New WASP App

As previously detailed, the parametric design software called WASP App is specifically tailored for 3D printing with clay. This software empowers users to craft their own designs, exerting control over shape, size, texture, and cutting parameters. These models can subsequently be exported in gcode format, ready for direct printing. The software seamlessly integrates with WASP’s Clay 3D printers, facilitating even series production. Notably, WASP emphasizes that the WASP App caters to a broad spectrum of users, including those without prior experience in 3D modeling and cutting.

Presently, WASP App is already in version 0.2, slated for public availability from August onward. This forthcoming update will grant open access to the application via the web. The Italian company has confirmed its commitment to incorporating new functionalities in the months ahead. One key enhancement will enable the queuing of various gcodes within a single file. This feature will be seamlessly integrated into the latest iteration of Clay Line 3D printers, notably the WASP 40100, a high-capacity machine designed for large-scale production. Employing an internationally patented continuous feed system, this 3D printing solution offers automated production of 3D printed components on a 24/7 basis. Further information on the WASP App can be found HERE.

*All photo credits: WASP