Cornell Revolutionizes Realistic Ear Grafts With 3D Printed Ear

3D printing has rapidly conquered the medical field, opening up a host of new possibilities. The technology enables the creation of complex structures with unrivaled precision, paving the way for new approaches in surgery, prosthetics, and tissue engineering. In this vein, researchers at Weill Cornell Medicine and Cornell Engineering have fabricated a realistic replica of an adult human ear using advanced tissue engineering and a 3D printer. This study indicates the potential for crafting grafts with precise shapes and suitable biomechanical properties, offering promising prospects, particularly for individuals with congenital ear deformities.

Nowadays, many surgeons resort to a procedure where they remove cartilage from a child’s ribs to build a replacement ear. However, this operation is very often painful and leaves scars. Although the resulting graft can be shaped to resemble the original ear, it generally lacks the same flexibility. So how have researchers managed to realistically reproduce a human ear using 3D printing?

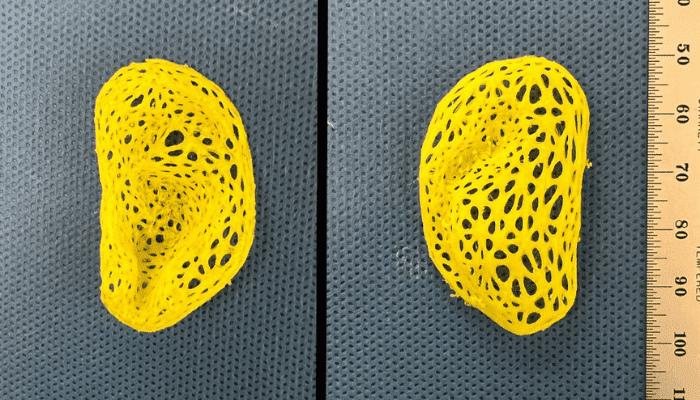

The 3D printed ear graph. (Photo Credits: Weill Cornell Medicine)

How 3D Printing Revolutionizes Ear Reconstruction

One method of creating a more realistic replacement ear involves the use of chondrocytes, the cells that make cartilage. Dr. Jason Spector (Chief of the Division of Plastic and Reconstructive Surgery at NewYork-Presbyterian/Weill Cornell Medical Center and Professor of Plastic Surgery at Weill Cornell Medicine) and his colleagues have previously used animal-derived chondrocytes to grow a structure composed of collagen, an essential component of cartilage. Although these grafts grew well, over time the distinct shape of the ear was lost. Dr. Spector explains: “Ear reconstruction requires multiple surgeries and an incredible amount of artistry and finesse. This new technology may eventually provide an option that feels real for thousands needing surgery to correct outer ear deformities.”

To solve the problem of ear shape, Dr. Spector and his team used sterilized animal cartilage, previously treated to prevent immune system reactions. They then inserted it into a complex plastic structure designed to mimic the shape of an ear, created using a 3D printer based on data from a human ear. These pieces of cartilage act as internal supports, helping to form new tissue within the structure. Strength tests were carried out to investigate the performance of the replicas, and they showed that they had an elasticity close to that of human ear cartilage.

Researchers at Weill Cornell Medicine have strived to develop improved 3D printed ear replicas as early as 2013. (Photo Credits: Weill Cornell Medicine)

However, the material employed lacked the strength of natural cartilage, making it prone to tearing. Dr. Spector proposed a solution by considering the addition of chondrocytes, ideally sourced from a small segment of cartilage in the recipient’s ear. These cells would facilitate the production of elastic proteins crucial for fortifying ear cartilage strength.

What do you think about this 3D printed ear? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.