Top 5 Videos: Revolutionary 3D Printing Technology Transforms Artificial Eyes for Patients

Get ready for an exciting lineup of this week’s top 5 videos! We kick off with a groundbreaking development in ocular prosthetics, where additive manufacturing technology is revolutionizing the creation of artificial eyes. Discover how the Herston Biofabrication Institute is conducting trials to evaluate the effectiveness of 3D printed eyes compared to handmade ones, offering accurate and customizable solutions for patients in need. Next, we take you behind the scenes of SolidCAM’s headquarters, exploring their venture into 3D printing and providing an exclusive glimpse into their operations. Brace yourself for a thought-provoking discussion on the controversial world of 3D printed guns, examining the rise of homemade firearms and the ongoing debate surrounding regulation and individual rights. Then, we shift gears to Georgetown, where a groundbreaking project is underway, constructing 100 3D-printed homes that aim to revolutionize the construction industry. Happy Sunday!

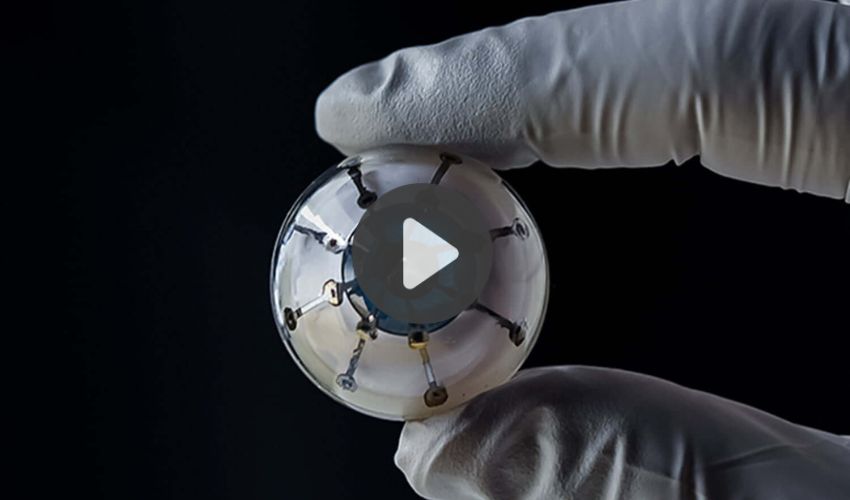

Top 1: Using 3D Printing for Creating Artificial Eyes for Patients

The field of ocular prosthetics is undergoing a significant transformation with the emergence of 3D printing technology. Ocularists like Nicholas Puls meticulously create prosthetic eyes for patients who have lost them due to cancer, trauma, or congenital conditions. The process involves intricate modeling and painting skills, resulting in individualized and realistic-looking prostheses. However, the Herston Biofabrication Institute is pioneering a trial to evaluate the effectiveness of 3D printed eyes compared to handmade ones. Using 3D scanning and high-resolution photographs, the team aims to produce accurate and customizable artificial eyes. This technology not only saves time but also allows for easy reproduction and distribution of prostheses to patients in need. While the machine-printed eyes are a promising advancement, ocularists believe that a hybrid approach, combining the strengths of human craftsmanship and 3D printing, is the optimal solution for achieving the best results.

Top 2: Visiting SolidCAM’s Headquarters

Recently, our team had the opportunity to visit SolidCAM’s Center of Operations in Israel. We were warmly welcomed by Dr. Emil Somekh, the Founder and CEO of SolidCAM, who provided insights into their brand expansion and venture into 3D printing. Accompanied by Michael Vinetski, the Vice President of Product Management, we had the chance to explore the milling area and later, under the guidance of Alexander Miasnikov, the Additive Technical Manager, we observed the operations of their 3D printers. Through our “Inside 3D Tour” series, we aim to take you behind the scenes of leading companies in the additive manufacturing sector, offering a glimpse into what happens beyond the public eye. Watch the video below:

Top 3 : 3D Printed Interbody Spacers by HEDRON

Globus Medical recently performed the first procedure using the Hedron IA implant, a 3D printed integrated ALIF (anterior lumbar interbody fusion) spacer designed for vertebral body fixation. The outpatient procedure took place at Englewood Health in New Jersey and was carried out by Joshua S Rovner. The Hedron IA spacer, intended for patients with degenerative disc disease, offers the benefits of minimally invasive surgery, easy insertion, and a sturdy construct. Its biomimetic porous scaffold promotes bone formation and achieves a balance of strength and porosity, leading to improved patient outcomes compared to traditional implants. Check out the video!

Top 4: Six 3D Printed Homes are for Sale in Georgetown

Georgetown, the fastest-growing city in America, is making headlines with its groundbreaking development of 100 3D-printed houses. This innovative project, a collaboration between Lennar and Austin-based ICON, is set to revolutionize the construction industry. Six of these futuristic homes, priced between $475,000 and $565,000, will be available for sale this weekend. With floorplans ranging from approximately 1,574 to 2,112 square feet, these homes boast three to four bedrooms and two to three bathrooms. The introduction of the world’s first 3D-printed community not only reduces construction costs and waste but also delivers homes at a faster pace. This significant milestone for Central Texas highlights the region’s emergence as a leader in technology. The Wolf Ranch community is still under development, with only a quarter of the project completed thus far.

Top 5: Exploring the Process of IPA Recycling: Distillation for Resin 3D Printing

In this intriguing video, explored is the fascinating possibility of recycling resin saturated IPA (Isopropyl Alcohol) back into its crystal clear form. Join us as we delve into a highly effective method of reclaiming IPA using a common water distiller. Along the way, we share valuable safety tips to minimize any potential fire risk associated with the distillation process. Furthermore, we delve into the recovery efficiency of this technique and conduct a thorough cost analysis, shedding light on the economic viability of IPA reclamation. Don’t miss this insightful exploration of recycling resin saturated IPA and uncover the potential for sustainable and cost-effective practices in the realm of 3D printing.

What do you think of the new 3D printing technology revolutionising artificial eyes for patients? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: ABC News