NASA’s 3D Printed Circuits Reach New Heights in Space Exploration

In recent years, the field of additive manufacturing, also known as 3D printing, has been rapidly gaining popularity across various industries. Its ability to offer customization, innovative design, and improved performance has led to its widespread adoption in diverse fields. Among the many industries exploring the potential of 3D printing, space exploration remains at the forefront.

NASA, the renowned space agency, has been actively researching and developing this groundbreaking technology for use in space missions. Collaborating with academic institutions, NASA engineers recently achieved a significant milestone by testing hybrid printed electronic circuits near the edge of space, marking a crucial step in the evolution of 3D printing technology.

On the Suborbital Technology Experiment Carrier-9 (SubTEC-9) mission, launched from NASA’s Wallops Flight Facility, engineers tested the viability of printed circuits in space conditions. The sounding rocket soared to an altitude of approximately 174 kilometers (108 miles), providing valuable data during its brief flight. This successful test showcases the potential of 3D printed electronic circuits in the development of smaller spacecraft with enhanced capabilities, offering new opportunities for space exploration.

“The uniqueness of this technology is being able to print a sensor actually where you need it,” said Dr. Margaret Samuels, electronics engineer at NASA’s Goddard Space Flight Center and co-leader of the SubTEC-9 experiment. “The big benefit is that it’s a space saver. We can print on 3-dimensional surfaces with traces of about 30 microns – half the width of a human hair – or smaller between components. It could provide other benefits for antennas and radio frequency applications.”

3D Printed Circuits Propel Space Technology Forward

This innovative approach not only saves space but also allows for the creation of intricate circuits with traces as thin as 30 microns – half the width of a human hair. With applications extending to antennas and radio frequency components, the possibilities for improved spacecraft design and performance become increasingly promising.

The collaboration between NASA’s Goddard Space Flight Center and the University of Maryland’s Laboratory for Physical Sciences (LPS) played a pivotal role in the success of the SubTEC-9 mission. Working together, these experts developed humidity-sensing printing ink and circuits, showcasing the power of collaborative efforts in advancing cutting-edge technologies.

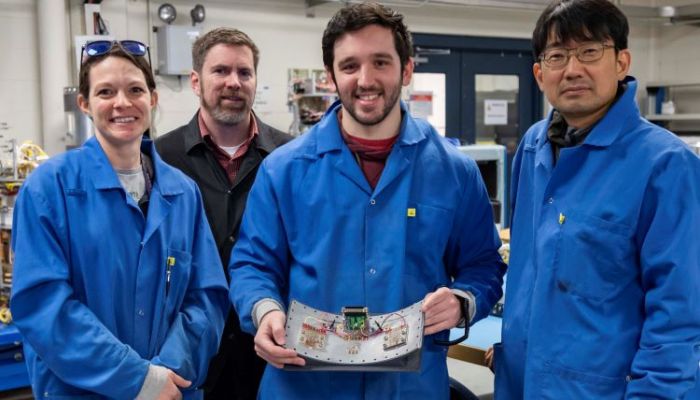

NASA and the University of Maryland’s Laboratory for Physical Sciences (LPS) engineering team showcased their printed electronics test assembly with a curved metal plate at a NASA Wallops Flight Facility lab before SubTEC-9’s historic technology test flight in April 2023. This marked the first flight of hybrid printed electronic circuits in space. (Credit: NASA/Berit Bland)

The success of the SubTEC-9 mission opens doors to further innovations. Engineers are exploring the potential of printing temperature sensors throughout a spacecraft’s interior, enabling better understanding of the effects of heating and cooling during space missions, particularly when approaching celestial bodies like the Sun.

As NASA and its partners continue to refine and expand the capabilities of 3D printing, the scientific community eagerly anticipates the future possibilities it holds for space exploration. From improved functionality in antenna connections to the use of printed X-ray instruments, the applications are extensive and far-reaching. For more information, find the original source HERE.

What do you think of the 3D printed circuits? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: NASA