Can 3D Printing Improve Hospital Outcomes?

Does additive manufacturing have a place in healthcare establishments? This is precisely the question being analyzed in research conducted by Dr. Atana Chaudhuri, associate professor of technology and operations management at Durham University Business School. He conducted a survey that illustrates how 3D technologies in hospitals can impact the operational practices of doctors from a variety of specialties, and also the quality of patient care. The results show that 3D printing is a key tool to alleviate hospital pressures, in terms of both time and expense. Dr. Chaudhuri, however, calls for caution: healthcare establishments must measure the advantages and constraints of such integration into their structure and ensure that healthcare staff is sufficiently trained.

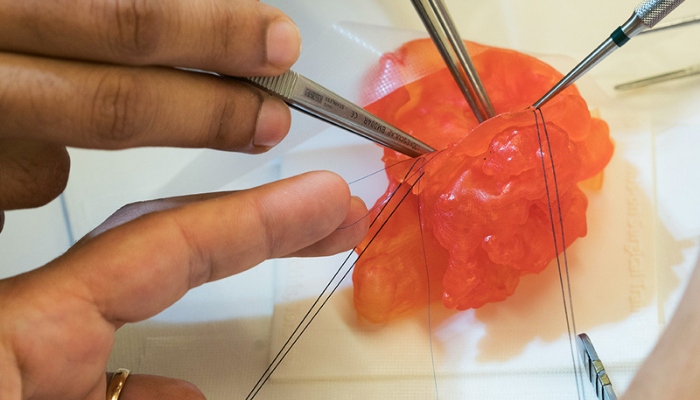

We could take many examples of hospitals in the United States that have integrated additive manufacturing into patient care. One of the top Children’s Hospitals in America, Seattle Children’s Hospital has been using the Stratasys Digital Anatomy 3D printer to plan and practice intricate surgeries for patients with rare conditions. This type of application within hospitals allows doctors to design anatomical models, imagine medical devices, or visualize their operations more precisely. This study from Dr. Chaudhuri is used to measure the effectiveness of 3D technologies in hospitals: do they really have a positive impact?

Digital Anatomy software and materials realistically mimic bone and tissue. (Photo Credit: Stratasys)

First observation of the report: additive manufacturing allows a reduction in operating time. Dr. Chaudhuri says: “Surgical operations lasting from 4 to 8 hours can be shortened from 1.5 to 2.5 hours if patient-specific instruments are used and from 25 to 30 minutes if only an anatomical model is used. used to plan the operation. ”An advantage that could allow more patients to be treated. This time dimension also concerns the convalescence of a patient. The study shows that the use of 3D printing would make it possible to recover better (about twice as fast) but above all to prevent the patient from returning to the hospital after his operation. This is particularly the case when an implant is transplanted: when this is 3D printed, it usually has a much longer lifespan than a conventional implant.

The report also claims that cooperation between doctors and 3D printing engineers is key: surgeons need to be integrated into the manufacturing process as quickly as possible so that the various 3D printed parts are optimal. Dr Chaudhuri adds: “ There is a myth that surgeons are not involved in 3D design or printing. But surgeons who learn how to segment, how to design a surgical guide, will be ahead of the rest. Ultimately, many surgeons will want to learn about 3D printing and it will be integrated into the medical curriculum. It should be noted that this also goes in the other direction: we tend to believe that 3D printing specialists do not understand the medical requirements but this is not always true, all the more so in recent times when manufacturing additive has been used extensively in the COVID-19 crisis.

Photo Credit: Formlabs

Finally, the study calls for caution: the integration of additive manufacturing represents definite benefits but it generates heavy and significant investments. However, hospital budgets are often quite tight. We could also say that the priority is elsewhere: additional staff, increase in nurses’ salaries, etc. Dr. Chaudhuri concludes: “The benefits can far outweigh the costs, both for hospitals and for patients. But, we need to know where to apply it and how to quantify the benefits.”

What do you think of integrating 3D printing into hospitals? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter , with all the latest news in 3D printing delivered straight to your inbox!