Digitally Woven Series Re-Recycles Plastic Into 3D Printed Creations

When art and design meet 3D printing, there is always a measure of excitement and anticipation to see where form meets function or where reality and vision collide. Indeed, the role of 3D printing within the design world has come far and made several bold statements along the way. Chiefly among them is the concept of sustainability, which has been incorporated into many projects aimed at zero waste or reusability. Two more names added to that list are British designer Gareth Neal and Dutch studio The New Raw, who partnered together for a collaboration series of 3D printed objects made out of recycled plastics.

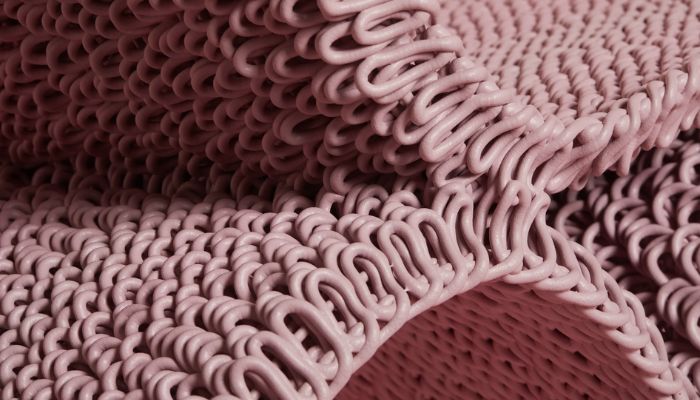

The Digitally Woven series, as it is known, is remarkable for two main things. First, the series’ use of ‘thrice-recycled’ plastic as a material demonstrates the reusability and viability of recycled products. And second, the material is extruded in interlocking loops, rather than the standard stacked layers of filament seen in 3D printing. The reason for this may not be evident. But while using and re-using materials over and over is a noble concept, it can pose risks as the structure of the material can break down over time and during reclamation. Thankfully the creators were able to circumvent this risk thanks to their innovative design style. The loops are able to retain their strength because of their interconnected layout, and the thickness of the extruded material. In addition, this method helped lower the overall amount of material needed to complete the project.

The fully 3D printed design resembles the loops on a knit or woven object.

This looping construction is not without its own reasoning either – as the collab team wanted to explore traditional crafting methods such as weaving and knitting through the medium of 3D printing. Because of the unique structure of the ‘woven’ print, they hoped that they would be able to ignore any small imperfections, as any irregularities would be supported and obscured by the overall structure of the loops. The printed object would therefore save time and reduce waste because any imperfections or misprints would continue to be supported by the strength of the surrounding structure.

“At the time of starting the project, The New Raw was printing in a very traditional style with layered prints that had come from putting 3D models through slicer tools. They asked me to look into how we could consider using their technology to capture craft techniques that they had started to explore to disguise the misprints,” Explains Neal, “The open weave structures were a totally new breakthrough and are really quite special in that they create structurally strong, lightweight objects using half the normal material use. I learned so much [and] it has also reinforced how important the close relationship is between artists and manufacturers. If a manufacturer is open to experimentation, a designer or a maker really can introduce new approaches to traditional methods.”

The Digitally Woven series was first on display at the London Design Festival, at the Material Matters fair. Since then, both have continued to work on the Digitally Woven line while pursuing their own new projects. For more information on Gareth Neal or The New Raw, feel free to check their websites for new products and designs.

The robotic arm-assisted 3D printer from The New Raw.

What do you think of the Digitally Woven series? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: James Champion