Scientists Eye 3D Printing for Next-Gen Flexible Batteries

3D printing has proven to be the perfect ally for a myriad of technologies. We’re increasingly witnessing a growing trend of 3D printing expanding into diverse fields with remarkable outcomes. Recent breakthroughs, such as the proposal by a team of researchers from various Chinese universities to 3D print flexible batteries, exemplify this trend. Their scientific article sets the stage for future advancements in manufacturing, particularly in the realm of flexible electronics.

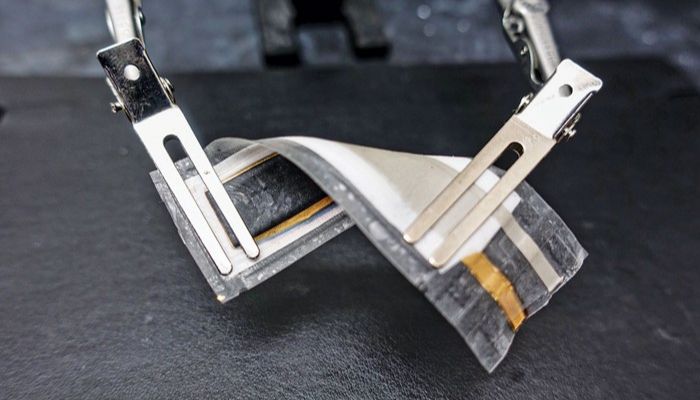

Since the inception of flexible batteries, the proliferation of wearable electronic devices has surged. From watches to foldable smartphones, smart clothing, and even medical implants, these batteries have found diverse applications. Their unique ability to bend and stretch without compromising functionality makes them ideal for devices with varied designs, seamlessly conforming to the contours of the human body. Just as flexible batteries have changed the technological landscape, so has 3D printing. Today, we’ll explore a groundbreaking collaboration among researchers from various universities in China, pioneering the fusion of additive manufacturing of flexible batteries.

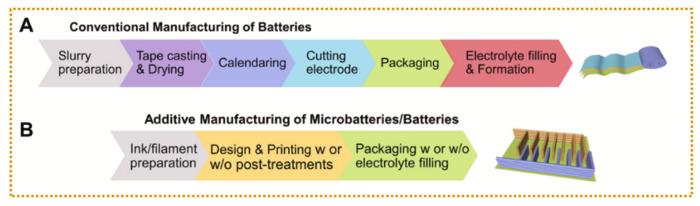

The concept of 3D printing flexible batteries holds promise, potentially streamlining the manufacturing process with fewer steps.Propuesta de impresión 3D de baterías flexibles. (Photo Credits: Journal of Power Sources)

Not So Flexible, Flexible Batteries

The conventional approach to manufacturing flexible batteries, known as “sludge coating,” involves combining cathodes, anodes, and electrolytes, which are the primary components of batteries. While effective, researchers note that this method falls short, leaving much to be desired in terms of customizing the battery’s architecture, configuration, and appearance.

Addressing this challenge, a collaborative team comprising researchers from China University of Petroleum, Qingdao University, and Wuhan University of Technology has devised a solution. Their approach is outlined in a comprehensive scientific article, offering a detailed review of the current manufacturing landscape and underscoring the potential benefits of incorporating 3D printing into the process. Through their proposal to merge these two technologies, they address both the challenges and solutions within this domain. Given the increasing presence of derivative products in the market, there is an urgent demand for advancements in production techniques to optimize outcomes.

A flexible battery pack. (Photo Credits: American Chemical Society)

The Benefits of 3D Printing in Battery Production

The researchers are optimistic about integrating 3D printing into flexible battery manufacturing, viewing it as a solution to many existing challenges. They highlight two key advantages: firstly, the ability to transform battery materials into printable inks, and secondly, the increased freedom in design and customization. They emphasize that this potential stems from 3D printing’s inherent attributes, such as precision, automation, customization, compatibility, efficiency, and cost-effectiveness. For instance, they envision the production of smaller batteries suitable for integration into medical implants as a tangible application of this technology.

The viewpoint presented by the Chinese researchers remains speculative at this stage, aimed at catalyzing future research and potentially revolutionizing flexible battery manufacturing. As an initial step, they have outlined several avenues warranting exploration. These include the advancement of 3D nano-printing technologies, conducting finite element simulations, and the development of advanced printable ink formulations. With the burgeoning market for portable devices, the appearance of the first 3D printed flexible batteries remains imminent. To find out more about this project, click here.

What do you think about the proposed utilization of 3D printing for flexible batteries? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Pexels