Krill Design on 3D Printing Furniture Using Oranges, Lemons and Coffee Grounds

As the topic of sustainability continues to grow in importance, 3D printing is increasingly at the center of the debate about greener production. One example of this comes from a possibly surprising source. Krill Design’s projects may in fact be proof that 3D printing and planet go hand in hand. The startup was founded by three students from Milan Polytechnic and now prints lamps, magazine racks and decorative objects for your home with materials made from recycled food such as oranges, lemons and coffee. We interviewed them to learn more!

3DN: Could you introduce yourself and tell us more about Krill Design?

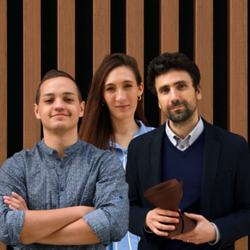

The Krill Design team (photo credits: acube).

We are Krill Design, an innovative startup born in Milan in 2018. We make 3D printed design products with biomaterials developed from recovered food waste instead of plastic. Krill Design was born from a meeting of three people united by different values, innovation, sustainability and design: Ivan Calimani, Martina Lamperti and Yack di Maio. The thinking of the three founders is quite simple: there are already several channels that intercept and valorize waste from the production of paper, glass and plastic, while for the organic by-products of the food chain, there are no suitable solutions. The three founders turned this problem into an opportunity by experimenting with the creation of innovative materials that, combined with 3D printing, resulted in a successful and environmentally friendly production process.

3DN: Why did you decide to use 3D printing?

3D printing was already well-known by of the founders, Yack and Martina, who had previously established a 3D printing center. Moreover, additive manufacturing allows us to be even more digital and sustainable. We manufacture our products on demand without creating large inventories in case of unsold products. In addition, 3D printing allows us to make products customizable and to constantly experiment internally.

3DN: How are your 100% natural and compostable Rekrill® materials produced?

Rekrill® is the material we developed in-house. We choose food waste from food and beverage companies. The process is the same for any type of waste: we dry it, finely chop it until it is micronized and compound it with a 100% vegetable material that gives the material its technical properties. The granulate obtained is then heated and extruded into filament by a machine. The coils are then installed on the molds.

The Rekrill® Orange material

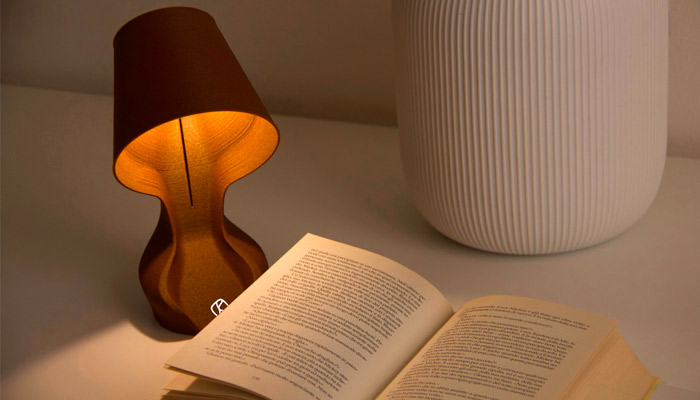

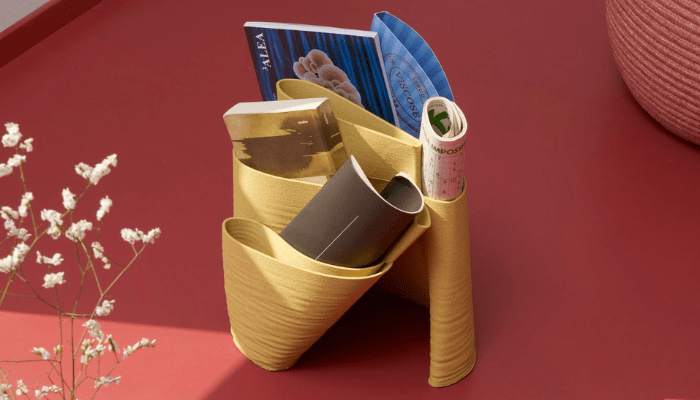

The material we print with is 100% biodegradable and compostable while still being designed to last. This and all our other products do not suddenly degrade as you might think. Our Rekrill® materials come in three different types: Orange, Lemon and Coffee, made from recycled orange peel, lemon peel and coffee grounds respectively. This is how our three collections of 3D printed home décor objects were born: Ribera, Amalfi and Napoli. Ohmie, our 3D printed lamp made from orange peels, is one of Krill Design’s most successful pieces. We are working on new biomaterials for 2023.

La lampada Ohmie.

3DN: What 3D printing technology do you use to create your products?

We use FDM technology, which allows us to successfully reuse waste. We have standard Prusa printers and a modified Creality CR10 Max. Our Ohmie lamp is produced in about 3 hours and the magazine rack in 5 hours. One of the challenges we faced was finding the perfect configuration of material for each product.

This incense holder was printed with Rekrill® Coffee material

3DN: How do you see the future development of Krill Design ?

In addition to consumer products, we also participate in circular economy projects with companies that have food waste and with whom we design ad hoc products from their waste. As mentioned earlier, 3D printing allows us to enter the world of digital manufacturing centers without creating more than necessary. In the future, we see Krill Design hubs scattered around the world to get closer to the end customer using local materials.

Krill Design’s 3D printed magazine rack made from recycled lemon peels

3DN: Any last words for our readers?

Our vision is easily summarized: “Feed the change, shape the future! Feel free to visit our website HERE if you would like more information.

What do you think of Krill Design’s 3D printed objects and their developed materials developed? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Krill Design

Honestly thank you so much for your page

Fascinating read! Krill Design’s approach to turning food waste into stylish, functional furniture is such an innovative win for sustainability. The ‘Recycling Heroes’ project with Whirlpool is especially inspiring—shows how circular design can merge eco-consciousness with modern aesthetics. Would love to see how this scales for broader impact. Brilliant work!