Crack Detection in Concrete, 3D Printed Buildings Made Possible by Adding Graphene Oxide

Engineering students at the public research university Royal Melbourne Institute of Technology (RMIT) in the Australian state of Victoria have developed an approach to produce a conductive and more stable concrete for 3D printing buildings. As part of their study, the scientists investigated how the addition of graphene oxide to concrete affects its printability in additive manufacturing. The study carried out by the scientists is the first of its kind and highlights the immense potential of concrete 3D printing in the construction sector.

The study by the Australian scientists from RMIT was recently published in the journal “Additive Manufacturing Letters”. In it, they detailed their observation that the electrical conductivity of concrete in additive manufacturing is improved by adding graphene oxide to the cement. Graphene oxide is a nanomaterial that is often used in electronic devices and batteries.

3D-printed concrete with added graphene oxide (photo credits: Jonathan Tran)

According to research leader and RMIT Associate Professor Jonathan Tran, the results of their investigations open up possibilities for the development of “smart” buildings, where in the future walls could act like sensors to detect and monitor small cracks as early as possible. Graphene oxide as an ingredient in the concrete mix enables an electrical circuit in concrete structures that can detect a wide range of environmental factors, such as temperature changes.

Further Benefits of Graphene Oxide for Concrete 3D Printing

Research leader and RMIT Associate Professor Tran recognizes 3D printing in the construction sector as an advantageous alternative to traditional production methods, as AM has considerable advantages when it comes to cost and sustainability. As Tran explains, “Current concrete structures are created using formwork, which is where you create a mold before pouring fresh concrete mixture into it. Formwork requires a lot of labor, time and money, and it often creates a lot of waste. With 3D printed concrete, not only does it help save time, money and labor, but you can also create more complex structures and reuse some construction waste in cement-based materials.”

This therefore is the underlying incentive for the research team to target 3D printing in this sector. In addition to the electrical conductivity of the concrete, he notes other advantages that the addition of graphene oxide brings to concrete 3D printing. For example, the material can be extruded more easily thanks to the graphene oxide component in the concrete. This would optimize the bond between the individual cement layers during construction, which could often pose a problem due to the fact that concrete 3D printing involves layering in the form of weaker bonds between the layers. Graphene oxide could therefore increase the strength of the 3D-printed concrete, by up to 10% to be precise.

Lead researcher and RMIT PhD student Junli Liu also emphasized that the strength of the concrete depends on the amount of graphene oxide in the cement mix. If too much graphene oxide is added, there is a risk of negatively affecting the strength and thus the manageability of the mixture. In addition, the concrete construction could suffer a shortened service life. Care must be taken to not impact the balance of the concrete, though the team is undergoing extensive testing to avoid just that.

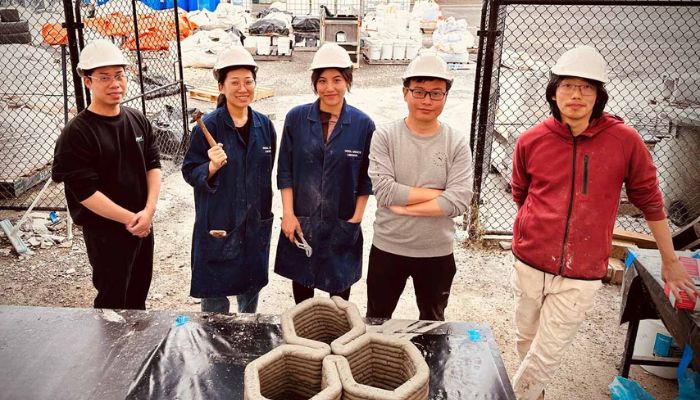

RMIT engineering students Hoang Khieu, Wen Si, Thanh Ha Nguyen, Junli Liu and Shuai Li (photo credits: Jonathan Tran)

Despite all the positive results from the tests, Tran makes it clear that further research is needed into the properties of concrete mixed with graphene oxide. The aim is to further investigate whether the newly developed cement mixture actually represents an improvement over conventional concrete in terms of strength. However, the researchers’ next project will initially be to investigate the electrical conductivity of the graphene oxide in the concrete mixture, which would open new doors for concrete 3D printing in terms of strength, durability and printability in the construction industry.

What do you think of the study on graphene oxide in concrete for 3D printing in the construction industry? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: RMIT University (Jonathan Tran)