An exclusive interview with the creator of the BlackBelt 3D printer

Back in May, we introduced you to the BlackBelt 3D printer, the first 3D printer that incorporates a conveyor belt into their 3D printing process. Since publishing our article, the buzz surrounding this printer has yet to stop, in part thanks to their Kickstarter campaign that has already raised €75,836, surpassing their original goal of €50,000. With the creation of this innovative machine, makers are now given the chance to create their objects without worrying about the length, with a few examples of chairs and leg prostheses that were printed using the BlackBelt on their website. To learn more about the BlackBelt printer and team, we decided to sit down with Stephan Schürmann, the founder of BlackBelt, to get the full scoop.

3DN: What is your connection to 3D printing and how did the idea of BlackBelt come to you?

First of all, I wanted to emphasize that I am not the first person to have had this idea of incorporating a conveyor belt into a 3D printer, but I am the first to actually implement it. It was during my design studies on industrial products at the Fontys International Campus in Venlo, that I had my first contact with a 3D printer. It was here where I became very dedicated to 3D printing and also where I learned how to design for 3D printing. From the beginning, I found that the existing technology is neither mature nor simple in its operation. During one of my classes, I had a project that’s goal was for me to design a user-friendly 3D printer. My work resembled the picture below. At the end of my studies, I wrote a thesis on the filament manufacturer colorFabb, in which I built a 3D printed bike.

Stephan’s Graduation Project

3DN: How does the 3D printer work and what challenges did you have to overcome during the development process?

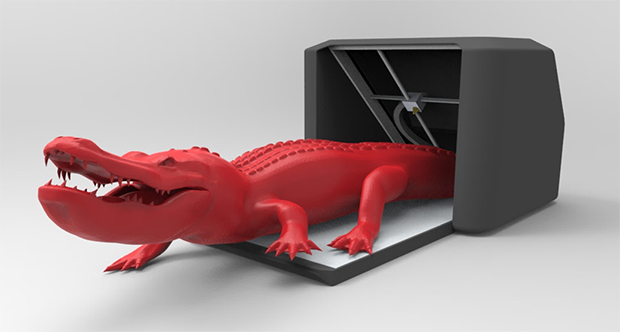

The 3D BlackBelt printer builds the object from the side onto the assembly line, i.e. at a certain angle. During the construction of the machine, the assembly line worried me the most because, in spite of its length and mobility, it still had to be a stable pressure bed. It took a lot of trials with different materials until we finally decided on a carbon fiber composite.

The BlackBelt 3D printer

3DN: Where do you see BlackBelt in the next 10 years?

When we finish our Kickstarter campaign, we want to build a production line and develop a user-friendly software. At the moment, I can only speculate about the future of BlackBelt, as the size, structure, and direction into which BlackBelt ultimately goes will depend heavily on the Kickstarter campaign. However, we have already considered different scenarios as to how we will build the company.

We believe that in the next 10 years households will not yet be equipped with a 3D printer. However, there are many different industrial applications that can benefit from our technology. Our vision is that in at least 10 years, this printing technology will be an established production tool that will be used in many areas.

For the moment, the BlackBelt 3D printer is currently available on their Kickstarter campaign for only €6,500, with the first Early Bird Reward already sold out. However, if you’re still sold on the BlackBelt printer, normal sales for the printer will begin at a price of €9,500 for their desktop version. For more information, be sure to check out the BlackBelt website as well as their Kickstarter campaign!

Do you think that BlackBelt will become a key production tool in the next 10 years? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!