Additive Manufacturing Plays A Growing Role in the Jewelry Industry

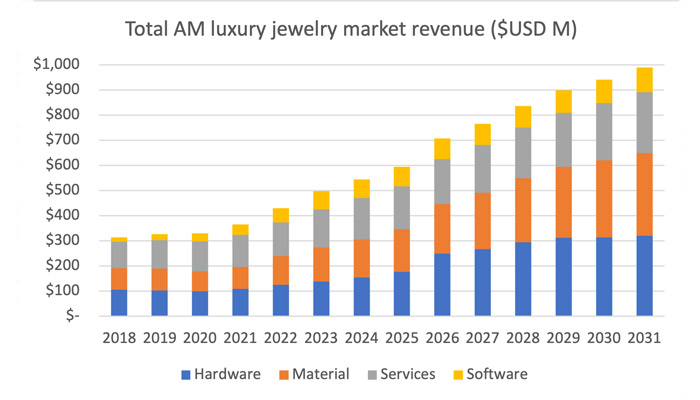

SmarTech Analysis has published a new study dedicated to the additive manufacturing market, this time focusing on the jewelry sector. According to the report, the 3D printed jewelry market is expected to reach a value of $989 million by 2031, up from $489 million this year, representing a 10% annual growth rate over the study period. This could be attributed to the emergence of precious metal printing processes, but to the declining costs of resin machines, which are popular with the industry, especially for producing molds for investment casting.

Jewelry is a complex market, most often associated with luxury, which relies on very traditional methods and long-standing craftsmanship. Yet it is also a field where innovation is key, where players must reinvent themselves to offer unique and sensational pieces. The use of additive manufacturing in jewelry is not new, and historically, the technology was primarily used in the design of prototypes and lost-wax casting models. This is still the case and the recently published report shows that these application cases hold a significant market share.

The evolution of the 3D printing and jewelry market (photo credits: SmarTech Analysis)

However, if the market for 3D printed jewelry is growing at an annual rate of 10% until 2031, it is mainly due to the development of processes such as binder jetting or developments around laser powder bed fusion, which allow the design of jewelry with precious metals. We can now rely on 3D printers to produce complex and unique rings, necklaces and bracelets. However, be aware of the costs that such a machine can represent – it is doubtful that all jewelers will immediately be able to equip themselves with a 3D metal printer, even if the price is lower than before.

The answer may lie in light curing: according to the SmarTech Analysis study, one of the factors driving market growth would be greater accessibility to resin 3D printing solutions. They also offer high resolution – stereolithography produces highly detailed parts. And today, manufacturers are striving to improve not only this print quality but also speed and volume. So, players in the jewelry market could count on more reliable and efficient 3D printers.

Finally, the study offers comprehensive forecasts for the different segments of the value chain, looking at 3D equipment, materials, but also software and services. Among the most influential players are names like Sisma, Formlabs, Desktop Metal and 3D Systems. If you want to know more, the report is available for purchase HERE.

What do you think of the role of 3D printing in jewelry? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

How is it possible to compare hand craftsmanship with 3D printing? It is day and night. Of course, they will be new designs of course but are not the same.

One state of art hand made jewelry it will be always better

3D printing is jewelry by ChatGPT. Also could be likened to living merely on Fast Food.