Empa Researchers develop 3D printing ink from Cellulose

The Swiss Federal Laboratories for Materials Science and Technology (Empa) have created a new ecological ink that is made from one of the main building blocks of plant material, cellulose. Thanks to their research, their ink may be the development needed to bring more environmentally friendly inks into fruition.

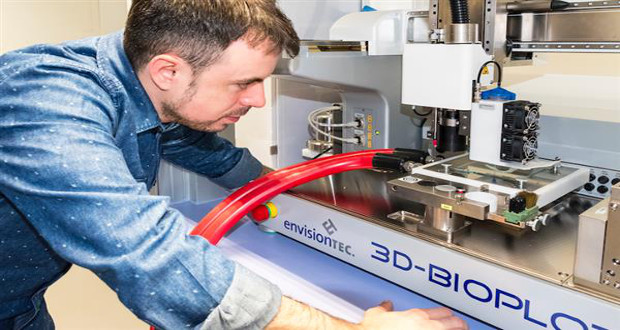

Working alongside researchers Dr. Gilberto Siqueira and Dr. Tanja Zimmermann from the Laboratory for Applied Wood Materials, as well as researchers from Harvard University and ETH Zurich, they were able to bring a new technology that has the power to bring 3D printing down an even more sustainable path.

The cellulose nanocrystals under a microscope

The ink is made up of nanocrystals, that are created using cellulose- a glucose packed structure that is found in wood. As cellulose doesn’t naturally take the form of a crystal, the researchers found parts of the structure where the cellulose fibrils, the small, slender fibers, had a more ordered structure. Once found, researchers applied an acid treatment that left them with the nanocrystals, tiny rod-shaped structures that were 120 nanometers long and 6.5 nanometers in diameter.

The places with a higher degree of order appear in a more crystalline form. And it is these sections, which we can purify with acid, that we require for our research,” explained Dr.Siqueira.

One of the biggest challenges that the team of researchers met was ensuring that they attained the elastic consistency that would allow the material to be squeezed through the nozzle of the 3D printer, as the ink needed to be “thick” enough to keep the material in the required shape before it dried and hardened. This wasn’t the only challenge that the researchers faced when creating their ink. In one of their trials, they used a water-based ink that ended up creating a fragile structure that would be of no use. After, researchers decided to put the CNC into a polymer-based mix. While, this shouldn’t have worked in theory, since polymers are “water-repellent or hydrophobic” and cellulose attracts water as “it is hydrophilic”, they fortunately succeeded when printing them together, as it hardened under UV radiation, giving them a product with all the conditions they were looking for.

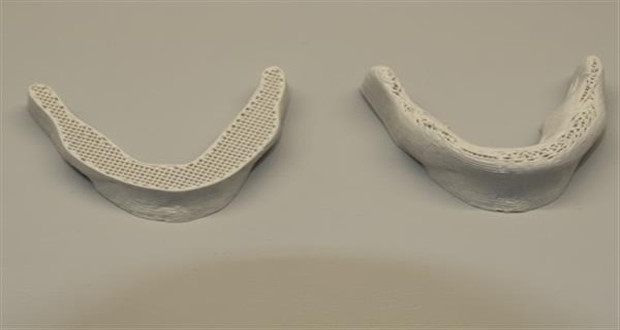

A jaw bone printed using the cellulose based ink

Thanks to these researchers, this technology has the potential for biomedical applications and implants, as the microstructures have outstanding mechanical properties. In addition, there are other advantages to this ink such as it being biologically safe for the body as well as it being a renewable resource.

“The most important area of application for me is in biomedicine,” explained Dr. Siqueira, “for example in implants or prostheses.” Today, the researchers are continuing to develop their ink along with students with the aim of finding new ways to develop their 3D printing material for other applications.

Watch the printing in action:

Be sure to check out their paper on their findings here.

What do you think of this new environmentally friendly 3D printing ink? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!