Shanghai Electric Adopts High-Performance 3D Printing Solution From IEMAI and Victrex

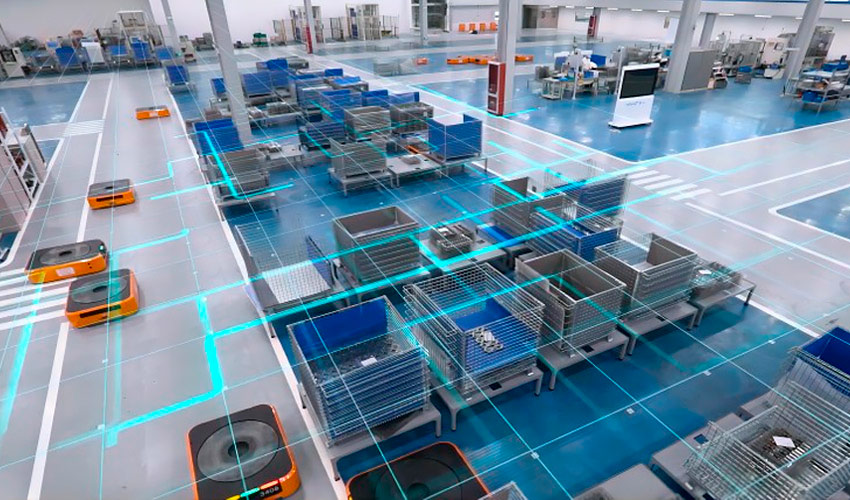

High-performance plastics for additive manufacturing are seeing significant demand at the industrial level. Many companies are already taking advantage of 3D technologies and advances in materials to produce parts with higher mechanical properties. One such company is Shanghai Electric, a leading global provider of industrial quality system solutions, with a focus on energy, manufacturing and digital intelligence integration. The company has turned to Victrex and IEMAI’s high-performance material 3D printing solution for the creation of a special-purpose binocular camera mounting bracket. This implementation aligns with a growing move towards manufacturing lighter parts that still have superior properties.

The use of advanced plastics is expanding significantly around the world, with a clear trend observed in the additive manufacturing sector as well. In fact, according to a study published by Markets and Markets, the market for high-performance polymers for 3D printing is expected to reach a value of $362 million by 2028, with a compound annual growth of 24%. This demand is due, among other factors, to the fact that low-cost plastics, such as ABS and PLA, do not offer enough strength for end-use parts in the most demanding industries. Meanwhile, high-performance 3D printing polymers make it possible to create engineering parts with high strength, light weight and durability. These benefits were key to the manufacturing of the mounting bracket carried out by Shanghai Electric thanks to materials from IEMAI and Victrex.

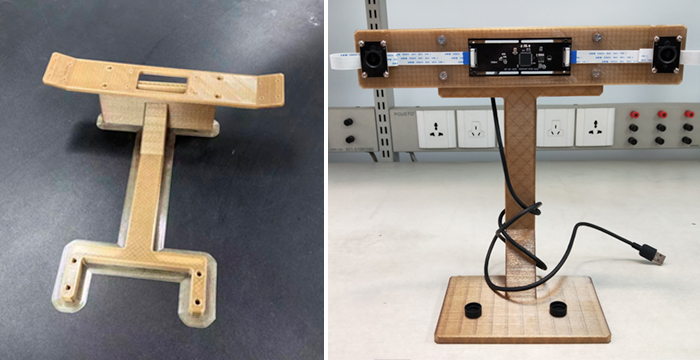

Shanghai Electric is turning to high-performance polymers to make a special-purpose binocular camera mounting bracket

PEEK 3D Printing for Binocular Cameras

Binocular cameras provide stereo vision thanks to the depth information obtained from the scene (done by calculating the disparity between two cameras), thus achieving 3D reconstruction and depth perception. However, the accuracy and stability of the calibration of the positions between the two cameras greatly impact the reconstruction’s accuracy. It is for this reason that there are high demands on the stability and conformal accuracy of the binocular camera mounting bracket. Thus, the overall performance of the materials used for the bracket are key, as it may be subjected to extreme temperature and humidity differences or external force conditions. In this context, the use of high-performance materials for 3D printing was the best option.

As we have seen on numerous occasions, polyetheretheretherketone (PEEK) is a very interesting plastic material option for a multitude of applications. It is a polymer that, although it is only 1/3 the density of aluminum, is eight times stronger. Thus, the so-called “golden plastic” is an ideal solution for creating lightweight yet strong parts.

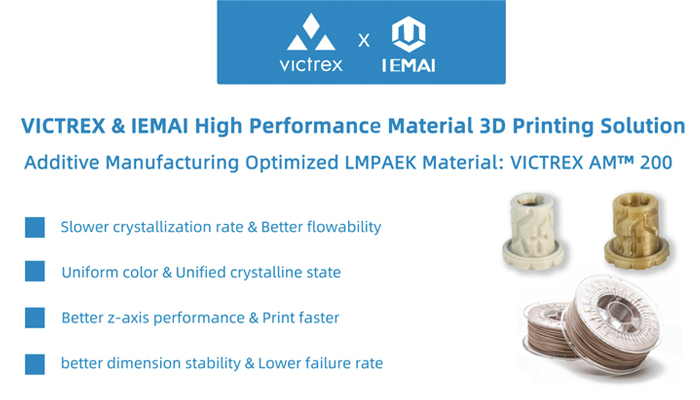

The benefits of the high performance material 3D printing solution from VICTREX and IEMAI

In the case of Shanghai Electric, the material was used in the creation of the binocular camera holder which, due to its special usage scenarios, has very demanding requirements in terms of material performance. The integration of this technology was made possible through collaboration between VICTREX, a leader in high-performance PEEK and PAEK solutions, and IEMAI, a Chinese high-tech company that focuses on research and development and 3D printing production.

This cooperation enabled Shanghai Electric to use the VICTREX AM™ 200 material, a material optimized for additive manufacturing, with IEMAI’s MAGIC-HT-L high-performance, high-temperature 3D printer. The machine in question uses FFF technology and has a maximum manufacturing volume of 310 × 310 × 480 mm. Its ability to reach a printing temperature of up to 450°C makes it capable of working with high-performance polymers such as PEEK, PEKK, PEI, as well as more standard and engineering polymers. Furthermore, IEMAI’s MAGIC-HT-L 3D printer has a modular mechanism in the extruder that facilitates maintenance and supports printing with water-soluble support materials.

The 3D binocular camera holder made by Shanghai Electric before post-processing (left) and in action (right)

Among the benefits obtained from this technology, the final 3D printed parts have a more uniform crystallinity, higher dimensional stability and better Z-axis tensile strength. Compared to conventional PEEK materials, the Z-axis yield is higher, reaching 60% of the XY axis. This ensures uniform mechanical properties in all directions. In addition, the temperature and chemical properties of the material can effectively guarantee the use of the part under any extreme conditions.

In addition, IEMAI3D has recently updated its system for large format high-temperature 3D printers MAGIC-HT-MAX to provide better temperature accuracy. With optimized electric lifting dual heads, connected to the network, it can perform cloud OTA, monitoring, and control, allowing users to manage printers in bulk.

Shanghai Electric’s binocular camera holder was 3D printed with the MAGIC-HT-MAX from IEMAI

In any case, for Shanghai Electric, these high-performance systems provided a better guarantee of precision for the binocular camera mounting bracket. If you would like more information about the high-performance 3D printing solutions used for this application, do not hesitate to visit IEMAI’s website HERE.

What do you think of Shanghai Electric and the adoption of high-performance polymers? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: IEMAI / Victrex