The Top 3D Printed Robots

Robotics brings together all the technologies that make it possible to design autonomous machines; combining knowledge in electronics, mechanics, and even biology. This is a field that has evolved quite a bit since C-3PO first hit the movie screens in Star Wars in1973. Roboticists have been in constant search of innovations that result in greater speed and productivity. Today, we have smarter robots because of advancements in artificial intelligence, machine learning, and of course, additive manufacturing. Indeed, 3D printing is widely used to manufacture robots, whether in the prototyping or final production stage, to imagine structure, materials, and new functionality. This is why we wanted to present to you some of the fascinating 3D printed robots we’ve come across, everything from humanoids, research tools, or even DIY machines—a section that should be of interest to all makers!

DIY Projects

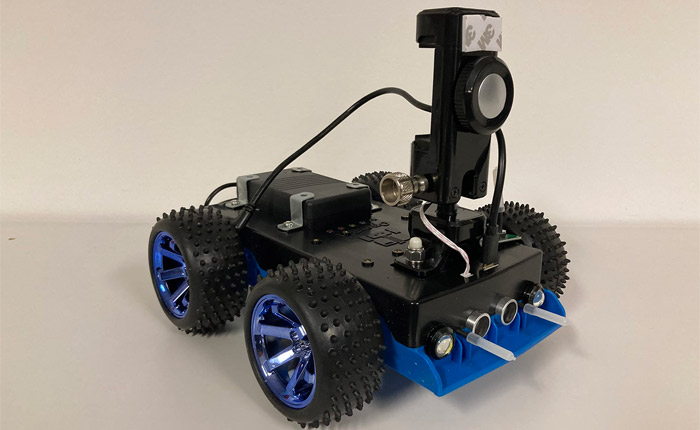

OpenBot

The OpenBot Foundation has set itself the goal of making robotics accessible to everyone. To this end, it has designed a small robot on wheels that can be controlled using a smartphone – the project’s motto is “Turning smartphones into robots”. It can be mounted directly in the home, and offers a wide range of functions. Part of the robot has been 3D printed using FDM technology – this includes the vehicle’s body. A number of sensors are integrated, enabling the robot to be handled with complete peace of mind. Various models are currently available, with prices ranging from $100 to $400.

Photo Credits : OpenBot

X-KIT From AOSEED

AOSEED’s DIY project offers an opportunity for children of all ages and creative minds to turn their ideas into reality. With the X-KIT, you can create toy robots using 3D design, 3D printing and coding. The Hub anclever application makes it easy to design parts that can be transformed into 3D printed models, compatible with any 3D printer. Whether you want to build trucks or intelligent robots, the possibilities are endless. What’s more, you can modify existing models as you see fit. A modular 3D design offers over 650 robotic components, enabling new models to be created simply by dragging and dropping. When encoding robots, two different modes are available, depending on your level of knowledge. Robots can be controlled using the program and a console. The Robot Creation Kit is currently available for $179.

Photo Credits: AOSEED

TOPS, the 3D Printed Quadrupedal Robot

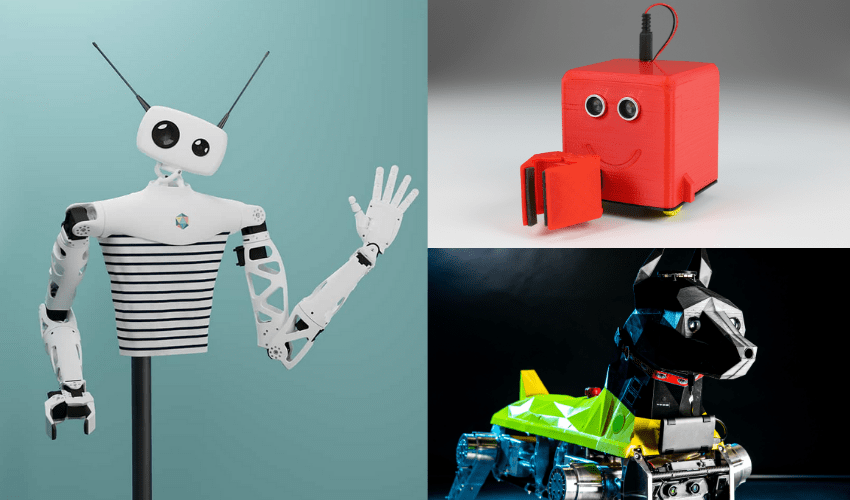

TOPS (Tranverser of Planar Surfaces or SPOT spelled backwards) is a partially 3D printed 12DOF quadrupedal robot made by Purdue University student Aaed Musa. Heavily inspired by James Bruton’s openDogV3 robot, TOPS took 4 months to build and cost $3300. Weighing a total of 29.6 lbs (13.43kg), around 1/3 of that or 9.98lbs (4.53kg) comes from 3D printed parts made on a Creality CP-01 3D printer, including custom QDD actuators and a 9:1 planetary gearbox. The robot also has 3D printed feet that have been coated in silicone and has been designed specifically to imitate the natural gait of an actual dog. In fact, it was so successful that the creator was even able to make the resulting robot dance! Check it out in the video below:

Otto DIY

Otto DIY is an interactive, educational robot designed to introduce children to robotics and coding. Developed with the support of HP, Otto is available in three versions. First is the HP Otto Builder kit, in which parts are supplied already printed, and the robot can then be fitted with wheels, a motor and additional tools for producing sounds and melodies. In the DIY Builder kit, 3D-printed parts are also supplied, requiring only the assembly of electronics to get it up and running. As for the DIY Maker kit, it comes with a printing guide and open source templates, ideal for those who have a 3D printer and wish to customize their robot. After printing, simply install the supplied electronics and program Otto’s movements, an intuitive task performed via a browser application. In this way, Otto offers not only an introduction to robotics, but also a fun and rewarding experience.

Humanoids

Atlas by Boston Dynamics

Boston Dynamics’ Atlas humanoid robots have recently caused quite a stir online with their performance during an obstacle course. Although they have already had some success, Boston Dynamics aims to test the limits of what is possible and continue developing Atlas to make robots withstand extreme conditions. The company relied on 3D printed components for the development of Atlas robots. For example, the legs are 3D printed, which made it possible to integrate hydraulic lines into the structure. Additive manufacturing has also been used to produce custom servo valves.

Reachy From Pollen Robotics

French company Pollen Robotics has developed Reachy, an open-source expressive humanoid, programmable in Python and 3D printed. Featuring a torso, head and arms, this robot excels at interacting with people and manipulating objects. The innovation lies in its recent ability to move around thanks to a new mobile base offering fluid navigation and automatic detection of the environment. Equipped with three omnidirectional wheels, multiple sensors and LiDAR for mapping, Reachy can now access a wider range of applications and an extended workspace. Its head can move freely, and its antennae can transmit emotions. What’s more, its arms, with dimensions and movements similar to those of an adult, can lift up to 500 grams.

The 3D Printed Robot PIB

The PIB (or Printable Intelligence Bot) is a 3D printable humanoid robot that can be printed at home. Developed by the German company PIB.Rocks, the robot serves as a versatile and customizable educational tool and platform designed to engage students in STEM learning. PIB features a modular design, allowing users to easily add and upgrade components such as sensors, actuators, and controllers, enabling a wide range of educational activities and projects. Upgrades and attachments can be downloaded directly from the company’s website, along with step-by-step guides and detailed tutorials to help users properly construct their bots. Additionally, PIB comes equipped with a graphical programming interface, ensuring accessibility for users across all proficiency levels. Designed to spark curiosity and creativity, the PIB aims to make learning STEM skills a fun and engaging experience for young learners.

Photo Credits: Ron Hübner, NN

Research Projects

Pleurobot the Ambphibious 3D Printed Robot

Pleurobot is a 3D-printed robot that mimics a salamander and was designed by the Ecole Polytechnique de Lausanne in Switzerland. This amphibious robot has practical application for neuroscientists, biomechanists, functional morphologists, and paleontologists as well as roboticists. For instance, Pleurobot will enable research that benefits quadriplegic patients as researchers gain better insights into anatomy and motor skills. Research may also focus on the evolution of the passage from a swimming animal to one that walks. Swiss engineers also replicated a nervous system using electronic components with a careful scan of a real salamander. Equipped with motors, Pleurobot can swim, crawl and walk like its amphibian counterparts.

“Micro-Bristle-Bots”

While most of the time human-designed robots are large, this is not always the case. At the Georgia Institute of Technology, researchers have developed microscopic 3D printed robots. Dubbed ‘micro-bristle-bots’, they are barely visible to the naked eye and can be controlled by tiny vibrations. Like ants, microscopic robots work in teams and are able to transport materials. To manufacture the ‘micro-bristle-bots’, the Georgia Tech team used Nanoscribe’s Photonic Professional GT 3D printer, based on the two-photon polymerization (TPP) process. According to the manufacturer, this technology achieves a high level of precision and detail and is ideally suited for micro-printing.

3D Printed Soft Robots from UC San Diego Jacobs School of Engineering

At the University of California San Diego’s Jacobs School of Engineering, engineers have been working on soft robotics, or the construction of robots from compliant materials, often taking significant inspiration from the movements of living organisms. One such recent project was when researchers designed and tested 3D-printed insect-like robotics. Using FDM and filaments like ABS or PLA, the insects were made using a flexoskeleton process that added rigid features to key components, allowing them to keep their flexibility. This is not the only 3D-printed soft robotics project coming from the school with more expected in the future.

Micro-Robots From Purdue University

For several years, researchers at Purdue University in Indiana have been focusing on the development of micro-robots the width of a human hair. These tiny robots can move through water at a speed of two millimeters per second, and can be remotely controlled to adjust their trajectory. A recent evolution is represented by 3D printed swimming micro-robots. Despite their simple appearance, with just a head and a tail, these micro-robots demonstrate considerable potential. Their tail, made of hydrogel which acts as a propeller, is designed using the two-photon polymerization 3D printing technique. This approach enables the micro-robot to adapt to different environments while maintaining its efficiency. The hope is that this initiative will continue to progress, paving the way for potential medical applications such as internal body navigation or precise drug delivery.

Filobot and I-Seed 3D Printed Robots Inspired by Nature

The Genoa-based Italian Institute of Technology (IIT) stands out for its innovative research into the use of 3D printing to design soft robots. Researchers are exploring soft robotics by marrying technological advances with biomimicry. Among their flagship projects, the I-Seed project aims to develop a new generation of miniaturized, flexible, autonomous and biodegradable robots using 4D printing. Inspired by plant seeds, these robots are able to monitor temperature, soil and air humidity, as well as detect pollutants. Another project is Filobot, a self-generating robot inspired by climbing plants. Equipped with a rotating head, it deposits a thermoplastic filament to gradually form its body, using FDM technology. Thanks to motion sensors, Filobot can orientate itself and move in response to various external stimuli, such as gravity, light and shade, mimicking the behaviour of plants. For the researchers, these advances could open up new horizons in the exploration of areas that are hostile or difficult for humans to access.

What do you think of our selection of 3D-printed robots? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!