Road Repairs with 3D Printing Technologies

In the world today there are 1.446 billion cars – that is, approximately one car for every five people. In order to keep transport running smoothly and efficiently and reduce nuisances like traffic and road closures, it is important to have high quality roads. However, a threat is posed by cracks and potholes, which can damage vehicles and cause accident risks. Additive manufacturing could solve this problem by fixing these road defects, according to researchers from Hebei University of Technology in China, and Michigan Technological University, USA.

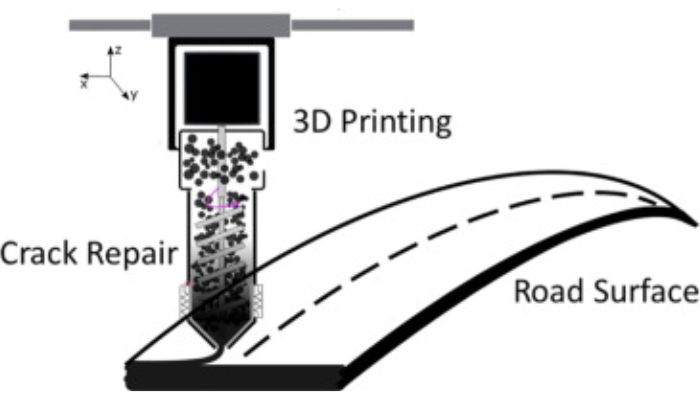

Traditional methods for pothole repair are various, and include cold, hot and jet patching. These methods have several disadvantages: human factors such as low automation, dependence on manpower, as well as a lack of preventative maintenance and material waste. 3D printing could provide an alternative with the application of 3D printing asphalt using extrusion technology – FFF. The repairs take several steps: obtention of 3D structural information of the problem, then rehabilitation of the issues. For the latter, the researchers offer two suggestions: in situ repairs, or treatment with prefabricated 3D structures. Finally, you would perform quality evaluation using tests.

Photo credit: Richard Jackson et al., 3D printing of asphalt and its effect on mechanical properties

Why Use 3D Printing Instead of Traditional Methods?

3D printing offers a number of advantages over traditional methods; for example, the automation level can be increased by the combination of 3D scanning and 3D modeling, thus reducing manpower consumption and road closure duration. Also, this method can be applied to preventive maintenance, and the steps can improve repairs quality and reduce material waste. In terms of application, 3D technologies could be combined with traditional distress detection, either through distress detection then application of the printer or through the two steps being combined in an asphalt 3D printer. This could create the optimum treatment of potholes and ensure that they are detected while still in the early stages, saving time and effort.

The researchers recommend a 3D printing robot equipped with a lithium battery crawler for in situ repair. They also mention the necessity to control the temperature according to the material’s optimum temperature and the required viscoelasticity of the stage of printing, as some stages (eg extrusion) require high viscoelasticity, but not so high that there is a risk of layer collapse.

Asphalt 3D printers are already a reality in some areas as part of experimental schemes, such as this one developed at the University of Leeds. (Photo credit: Doychinov, Viktor & Abdellatif, Mohamed & Kaddouh, Bilal & Malik, Bilal & Jackson-Mills, G & Fuentes, Raul & Cohn, Anthony & Richardson, Ricardo & Chudpooti, N & Robertson, Ian & Somjit, N. (2019). Infrastructure Robotics Research at the University of Leeds)

Similar examples of 3D printing being used to improve transport include the 3D printing of spare parts for trucks carrying freight across Europe, allowing companies to cut repair times and prevent logistics issues. You can find this full study on repairing road defects on ScienceDirect – the link is available HERE.

What do you think of 3D printing being used for road repairs? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credit: Burnaby Blacktop