Trucks Given 3D Printed Spare Parts

Transport can hardly do without additive manufacturing these days. Trucks in particular are extremely important for the transport of all kinds of goods: indeed, in 2021 U.S. trucks moved 10.93 billion tons of freight. Naturally, these vehicles require spare and replacement parts for trucks from time to time, but challenges can exist regarding their procurement. Be it the delivery, storage, quantity or even the quality of these parts. In order to specifically avoid these problems, the German company Stegmaier Group has looked into 3D printing and directly recognized its advantages in spare part manufacturing.

The company, which was founded in 1927 and is based in Baden-Württemberg, Germany, focuses on the manufacture and supply of trucks. Within this field, the vehicles are not infallible, and long journeys lead to parts wearing out more quickly. One fairly common problem is for the oil filler neck cap to break, causing the truck to lose engine oil and be hindered in its further journey. The subsequent effects can be loss of sales and other economically important events. Previously, the only solution was for Stegmaier Group to reorder the broken part and then replace it. However, the lead time of several days and the chance that perishable goods in particular would lose quality made the company rethink, and turn to 3D printing as a solution. As a result, the subsidiary STEBAG Land- und Nutzfahrzeugtechnik in Ellwangen now has a 3D printer for this purpose.

Mercedes-Benz uses 3D printing for spare part manufacture (Photo credit: Mercedes-Benz)

3D Printed Spare Parts Are Available Faster

Prototypes, small series or even tools and signs find their way from the 3D printer directly to the application at Stegmaier Group. The transport company lists the fact that these parts are available enormously quickly as just one of the many advantages. They are particularly impressed by the possibility of replacing metal parts with 3D-printed parts made of PA-6, for example. Although these are thermoplastics, they have low wear and tear and are tough and therefore durable – and if such a part breaks, a new part can be produced from the 3D printer in no time at all.

Sven Groß is project manager of the 3D printing STEBAG Land- und Nutzfahrzeugtechnik and provides further insight into the benefits this brings: “A 3D printer allows the spare parts inventory for rarely needed items to be reduced, because many parts are only needed a few times a year, but are only available in larger packaging units.” Above all, the fact that this eliminates the need for additional costs and CO2 emissions for transport is convincing for Stegmaier Group. The company relies on a 3D printer from Schubert Additive Solutions and produces officially licensed original parts from the manufacturer, which they can download from a database and 3D print directly.

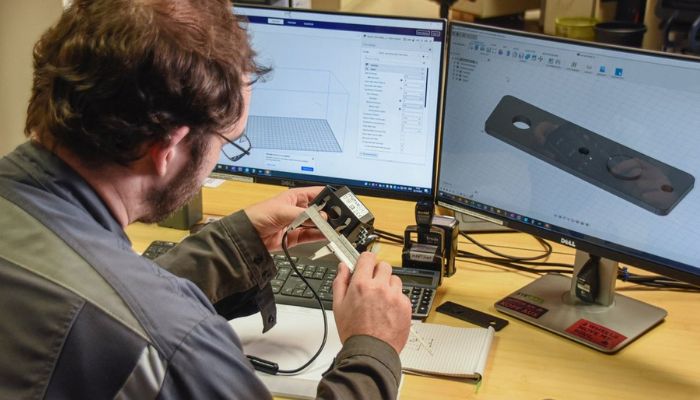

Sven Groß and the modeling of a mount for a rear view camera (Photo credit: Stegmaier Group)

What do you think of the use of 3D printing in transport? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credit: Mercedes Benz