Material Testing of 2PP 3D Printed Parts Has Been Successful

There is now a wide variety of processes in the field of innovative 3D printing technology. One of these is so-called two-photon polymerization (2PP), which is often used in applications for 3D printing in the micrometer range, such as in micro-optics and micromechanics. The process is also attractive for industrial applications and high-volume production. Considering that this method is used for high-precision applications, the standardization of material testing of 2PP 3D printed parts is highly relevant. This ensures, for example, that the parts produced have a certain level of quality and safety.

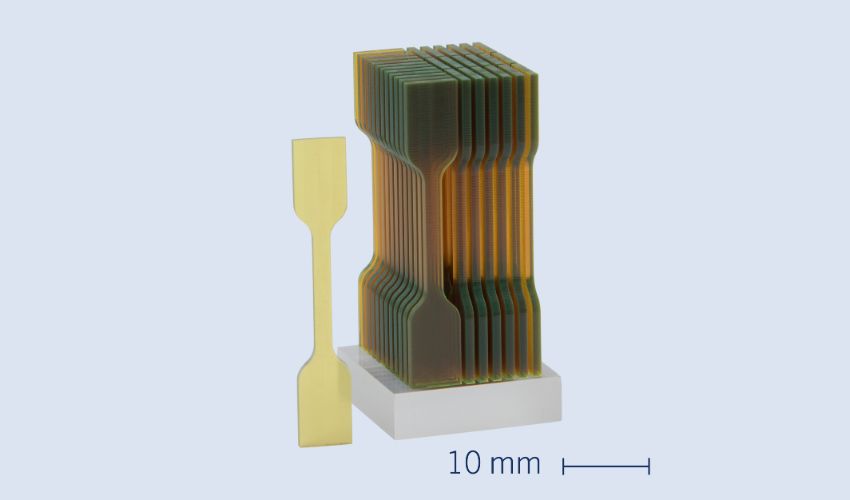

Now, in a multinational collaboration as part of a study by researchers from the Vienna University of Technology (TU Wien), the California Institute of Technology (Caltech) and RWTH Aachen University as well as material experts from UpNano GmbH, standardized material testing of (macroscale) 2PP 3D-printed parts, such as 35 mm test specimens in accordance with the ISO standard, has now been achieved for the first time. Through this, it has been possible as well to learn more about the mechanical properties of these parts.

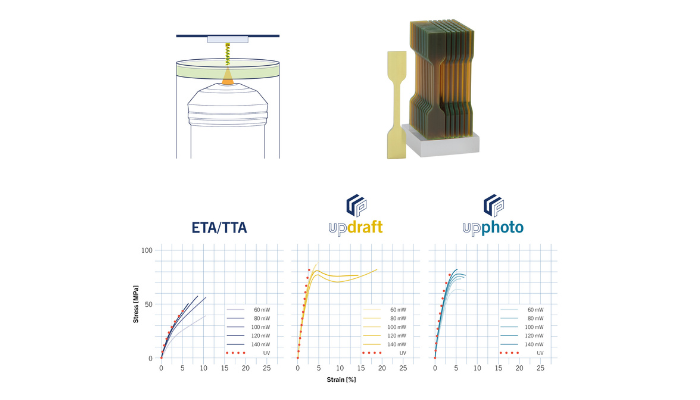

The NanoOne 2PP 3D printer

The study, which was published in “Advanced Materials”, represents the first testing of 2PP 3D-printed bulk samples with regard to their mechanical properties in the mm to cm range using standardized methods. The new findings are significant in that they help 2PP 3D printing to develop into a manufacturing method for mass production. This follows from the fact that the study establishes procedures for material testing that can meet the requirements of ISO standards. The study was carried out using the NanoOne 2PP 3D printer and resin materials. The research team’s results show that UpNano’s UpPhoto and UpDraft resins for macroscopic test specimens not only outperform traditional resin-based 3D printing with acrylic resin (ETA/TTA) in terms of material quality, but also require no post-treatment as they solidify quickly on their own.

The CEO of UpNano, Bernhard Küenburg, added, “Currently, there is no accepted standardized test method for micro- or nanoscale 2PP 3D-printed parts. But even if there were, the mechanical properties of a large-scale part could not simply be extrapolated from such small-scale samples. Therefore, the work of the TU Wien team and colleagues is a real breakthrough on the way to the industrial application of 2PP 3D-printing.”

Testing the Mechanical Properties of 2PP 3D Printed Parts

The mechanical properties tested for the 2PP 3D-printed 2PP material include tensile, flexural and hardness properties on the one hand and creep and fracture behavior on the other. The research team used the materials ETA/TTA (ethoxylated (20/3) trimethylolpropane triacrylate (ETA) in combination with trimethylolpropane triacrylate (TTA)) and UpNano UpPhoto and UpDraft. In addition, the NanoOne printer was used together with 10x and 5x objectives to help achieve a high printing speed, which was necessary for the large samples.

Team Lead Materials and Application at UpNano and last author of the study, Markus Lunzer, further explains, “One of the most remarkable results we obtained was that of the three materials studied, only UpPhoto and UpDraft were suitable for upscaling. This was due to their wide processing window and overall well-balanced properties. ETA/TTA, on the other hand, was found to be unsuitable due to its small processing window, stress-induced microcracking and generally low toughness of the final product.” This holds great potential for the additive manufacturing of microfluidic devices in particular, as complex internal microchannel structures can be produced in this way. In any case, it will be interesting to see how 2PP continues to advance and what new applications and parts we can see now that the possibility of standardization and testing has been introduced.

The testing results

What do you think of this standardized material testing of (macro-scale) 2PP 3D printed parts? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: UpNano