Clemson’s 3D Printed Fuel Cells Redefine Sustainable Energy Generation

Researchers at Clemson University have achieved a groundbreaking feat by harnessing the power of 3D printing to create protonic ceramic fuel cells (PCFCs), a technology poised to reshape the landscape of renewable energy. Unlike conventional energy sources that heavily rely on fossil fuels, PCFCs employ renewable fuels such as hydrogen, ammonia, alcohols, and sustainable hydrocarbons. This marks a significant step towards a greener and more sustainable approach to electricity generation. The challenge, however, has been scaling up the production of PCFCs to a level that makes them feasible for widespread adoption.

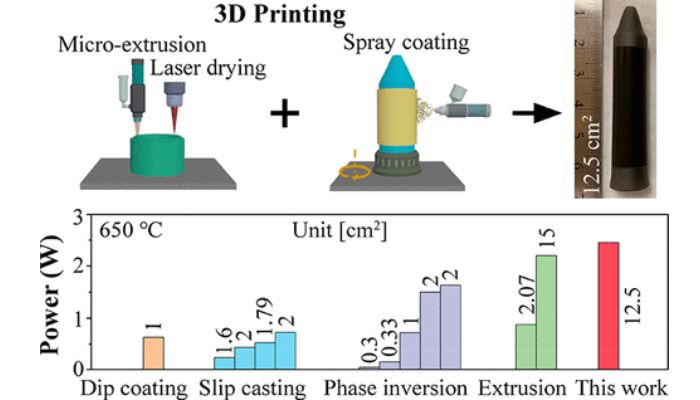

To address this hurdle, a team of researchers at Clemson’s Advanced Materials Research Laboratory turned to the capabilities of 3D printing. This innovative technology allows for the creation of complex and customizable objects with exceptional precision, which in the case of PCFCs, proved to be a game-changer in terms of manufacturing.

The team of researchers comprised Jiawei Zhang, Jianhua “Joshua” Tong, Bridget Sheridan, Kyle S. Brinkman, Minda Zou, Fei Peng, and Jacob Conrad (from left to right).

The team’s breakthrough came in the form of tubular PCFCs, a design that offers distinct advantages over traditional flat designs. Tubular PCFCs exhibit enhanced durability and sealing, making them more resilient and suitable for real-world applications. In a notable experiment, the researchers used hydrogen as fuel and tested a single fuel cell for 200 hours, consistently producing power throughout the test period. This achievement alone highlights the potential of 3D printed protonic ceramic fuel cells to offer improved precision, consistency, and cost-effectiveness compared to traditional manufacturing techniques.

The entire team of researchers at Clemson University, including Jiawei Zhang, Bridget Sheridan, Jacob Conrad, and others, reported their groundbreaking findings in a paper published in the esteemed journal ACS Energy Letters. Minda Zou, a Ph.D. candidate, led the research as the first author, with Jiawei Zhang and Professor Jianhua “Joshua” Tong serving as corresponding authors from the Department of Materials Science and Engineering.

Enabling Scalable Tubular Protonic Ceramic Fuel Cells Through 3D Printing (Photo credits: ACS Publications)

A New Era For 3D Printed Fuel Cells

The uniqueness of this research lies in the team’s success in 3D printing all three critical layers of a fuel cell—the anode, cathode, and electrolyte—in a single integrated process. Professor Tong emphasized the significance of this achievement by stating, “Nobody else has done that.” Furthermore, he highlighted the simplicity and cost-effectiveness of their method, which holds great promise for future commercialization.

While the current time required to 3D print a single fuel cell stands at around three hours, the researchers are already envisioning more advanced designs for the next phase of their work. With these advancements, the team anticipates the potential commercialization of 3D printed protonic ceramic fuel cells within the next five years.

The paper titled “3D Printing Enabled Highly Scalable Tubular Protonic Ceramic Fuel Cells” is a testament to the team’s dedication and innovative spirit. As renewable energy gains more attention in the global drive towards sustainability, technologies like 3D printed PCFCs offer a glimpse into a future where clean energy sources can be harnessed more efficiently and effectively. To access the original study, click the link HERE.

What do you think of Clemson’s 3D Printed Fuel Cells? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.